Natto food, and its prepn. method

A technology for food and natto, applied in food preparation, dairy products, food science and other directions, can solve the problems of unacceptable, bitter taste, dislike of eating, etc., to achieve the effect of comfortable and pure taste and elimination of ammonia odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

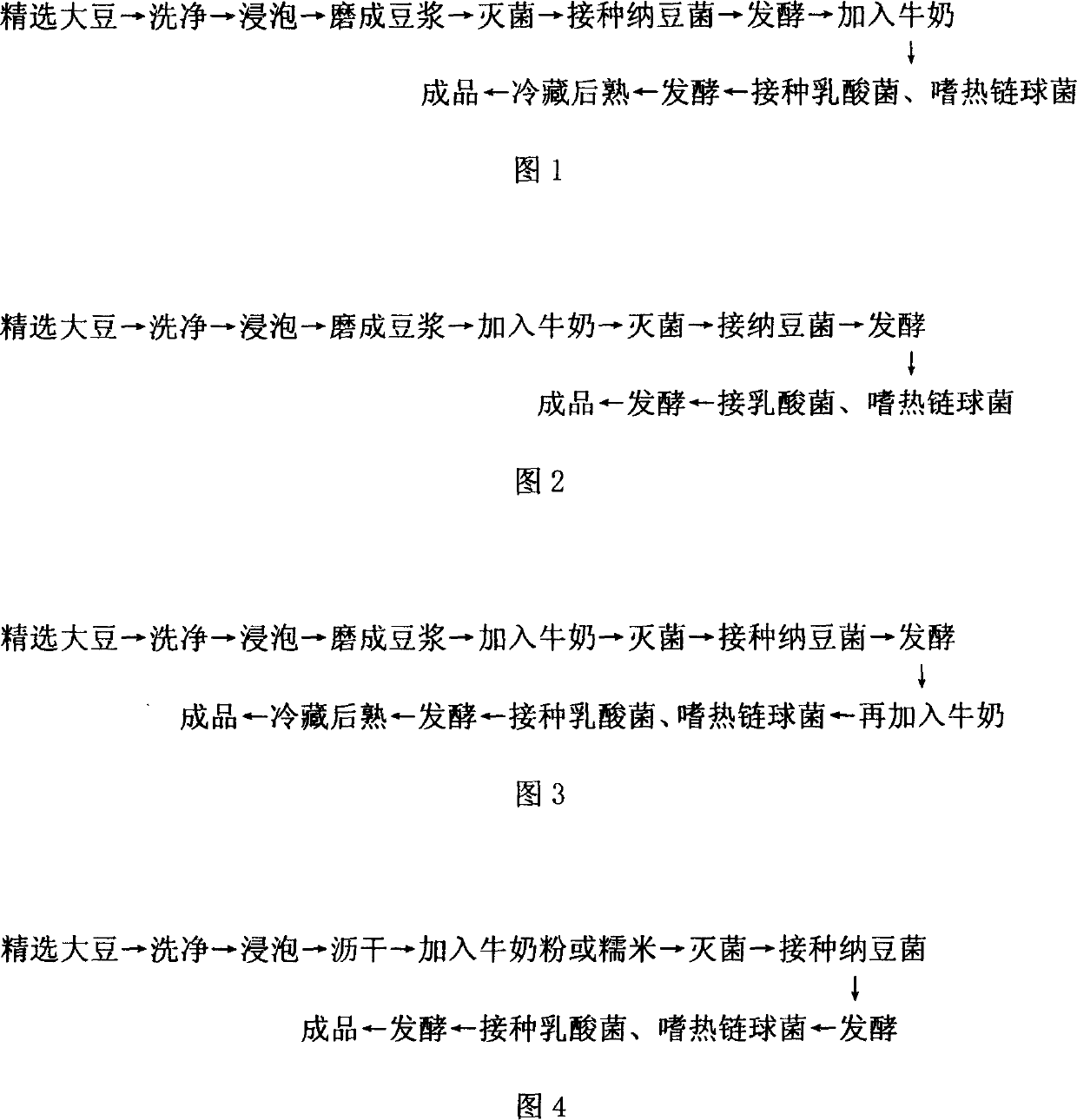

[0018] The natto food of the invention is prepared by inoculating soybeans, water, milk or milk powder or glutinous rice with Bacillus natto, fermenting, and then inoculating Lactobacillus bulgaricus and Streptococcus thermophilus for fermentation.

[0019] Embodiment 1 of the present invention as shown in Figure 1, the production process steps are: select 100 grams of soybeans, soak in 0.5% sodium bicarbonate solution for 12-24 hours, wash and drain, add 500 grams of water, grind into soybean milk, add 70-150 grams of sugar, 50-200 grams of fruit juice and other seasonings are placed in a container, sterilized, inoculated with Bacillus natto, sealed with gauze, placed in an environment of 28-45°C, and fermented for 12-72 hours. Add 16000 grams of fresh milk, add 800-1200 grams of sugar, inoculate Lactobacillus bulgaricus and Streptococcus thermophilus, place in 28-45°C environment, ferment for 1-5 hours, place in 0-4°C environment, refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com