Door brick of coke oven and preparation process thereof

A manufacturing method and a furnace door brick technology are applied to coke ovens, coke oven heating, coke oven parts and other directions, and can solve the problems of difficulty in removal, shortening the service life of furnace door bricks, damage to furnace door bricks, etc., and achieve removal of tar. Easy, improve labor conditions and labor intensity, improve the effect of finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

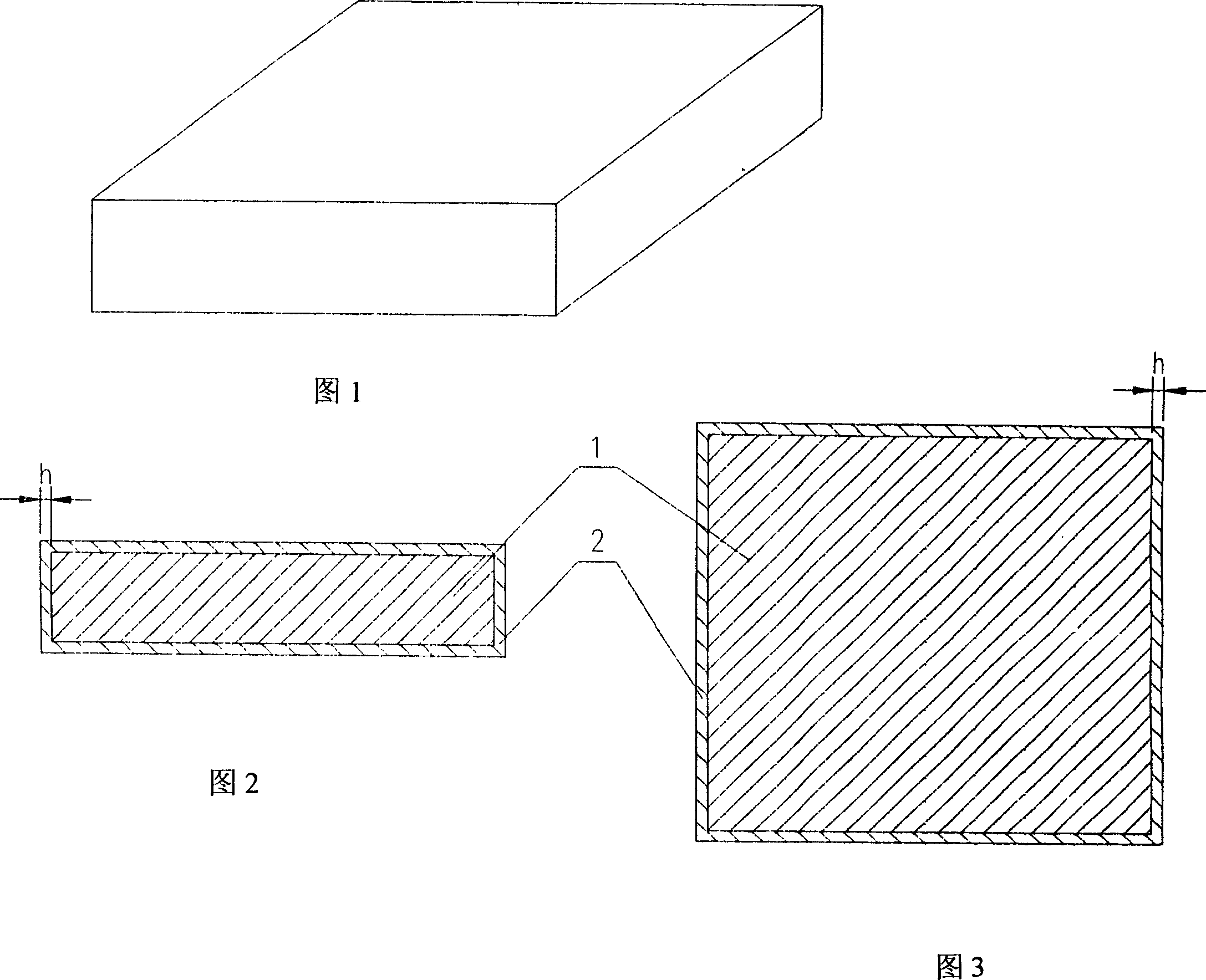

[0019] Referring to Figure 1, Figure 2 and Figure 3, brush or spray ceramic glaze or other glazes on the surface of the furnace door brick or brick 1 with a brush or spray gun, the thickness of the glaze layer 2 is about 0.2-4mm, and enter the kiln after drying Firing in a furnace, the maximum firing temperature is 1250-1400°C, and the temperature is kept for 2-10 hours. The furnace door brick is the finished product after it leaves the kiln. If the glaze layer 2 is less than 0.2 mm, it cannot play the role of the glaze layer; if it is greater than 4 mm, it is unnecessary, and it will also increase the cost and increase the difficulty of manufacture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com