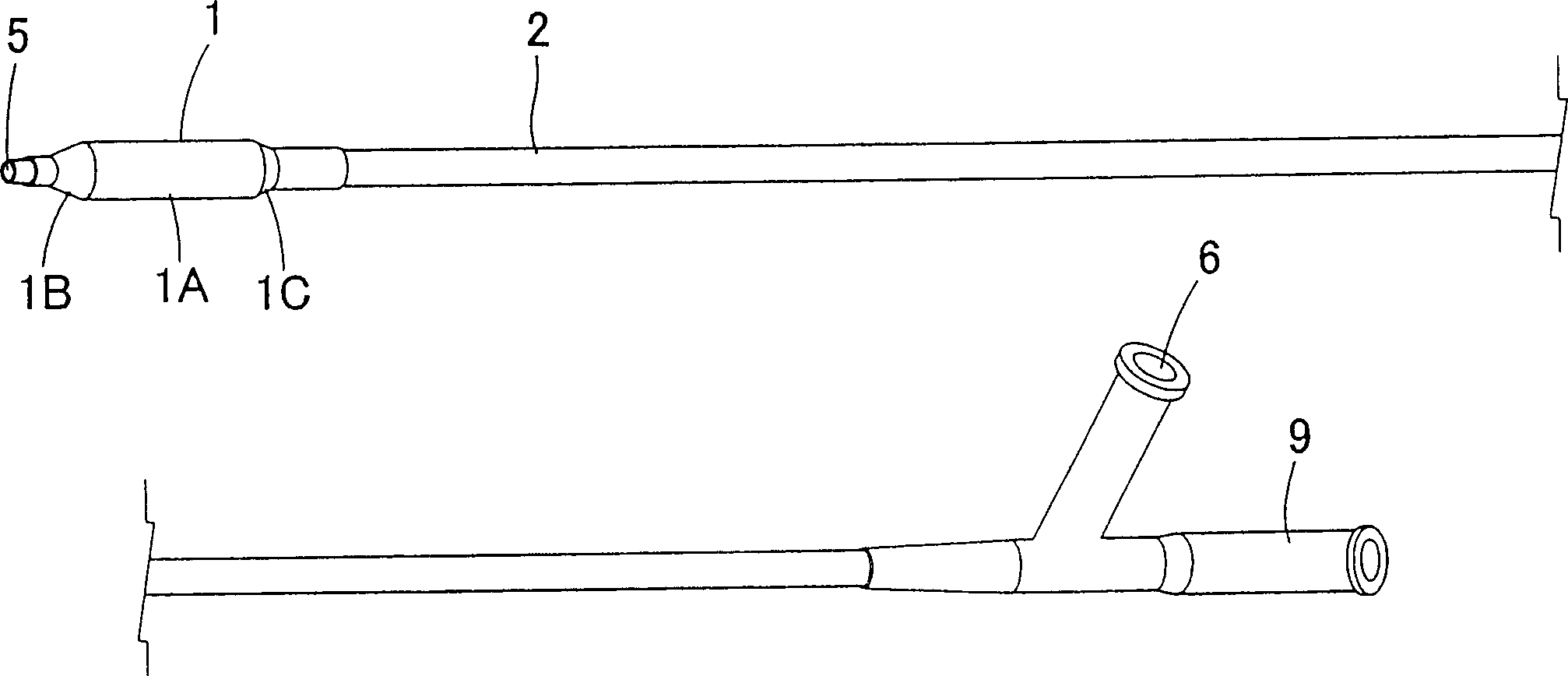

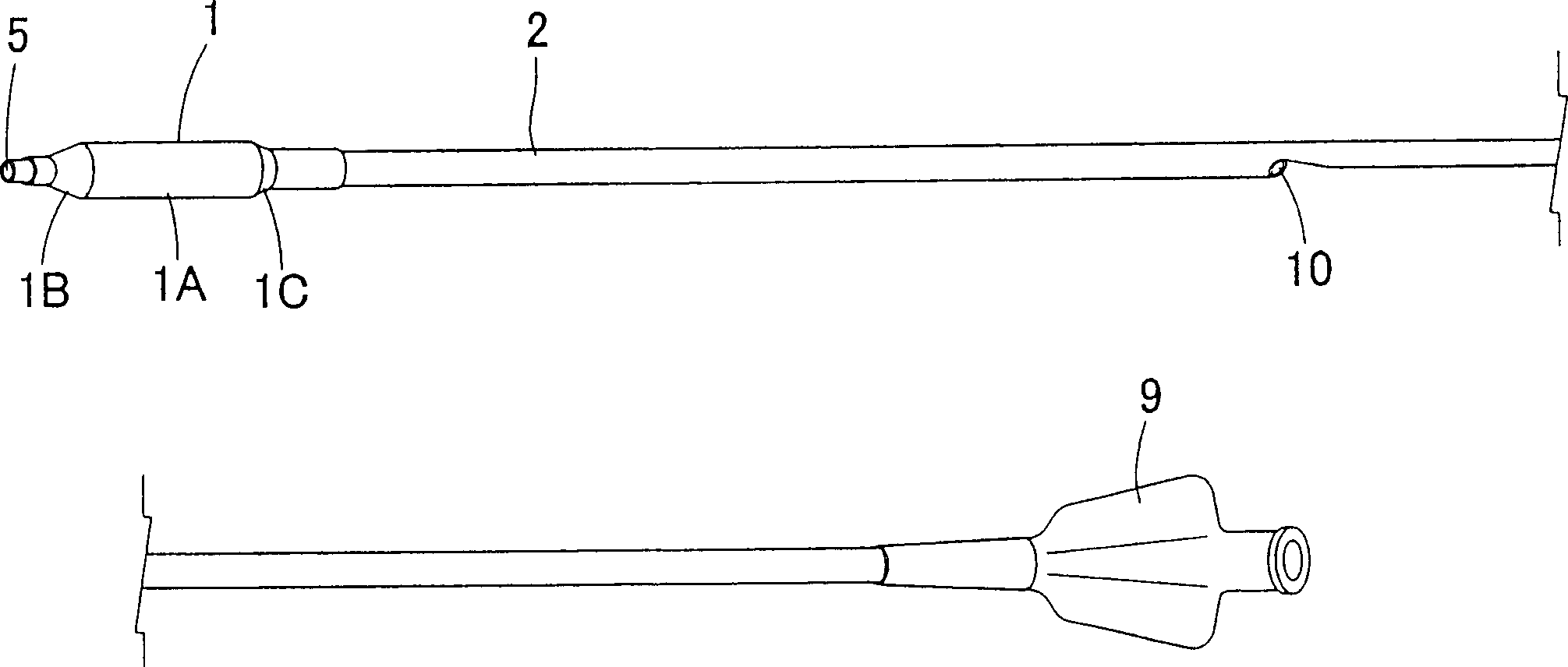

Stent delivery catheter

A catheter and balloon catheter technology, applied in catheters, stents, balloon catheters, etc., can solve problems such as reducing the sensitivity of balloon inflation and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

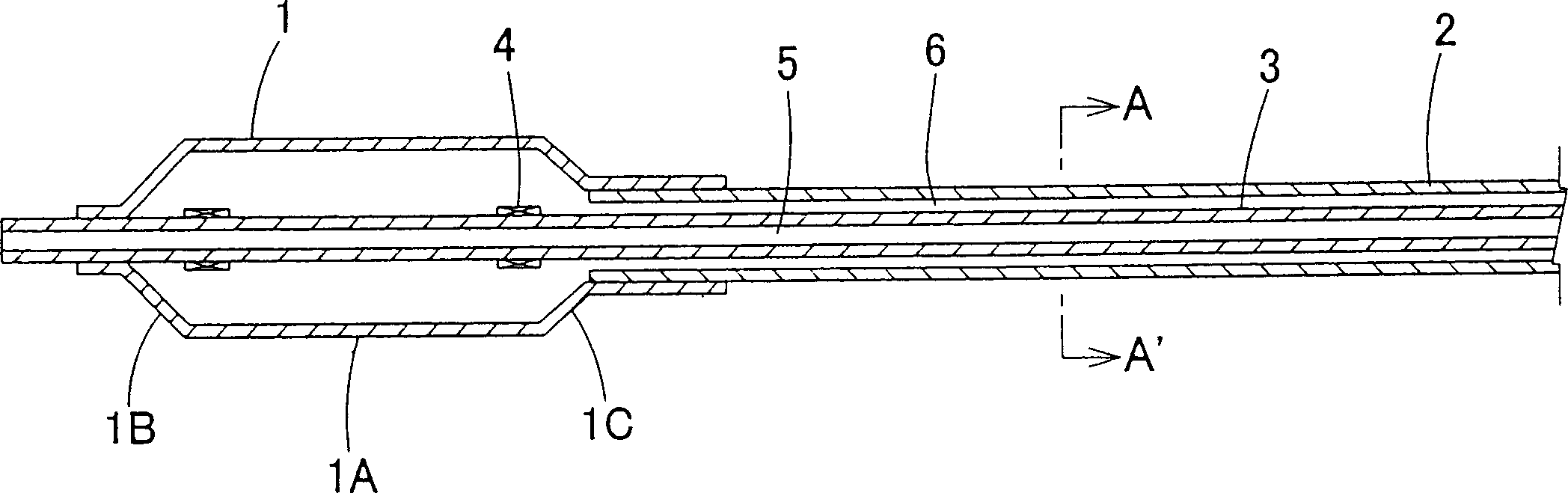

example 1

[0103] A tubular billet (inner diameter 0.51 mm, outer diameter 1.02 mm) was produced from a polyamide elastomer for extrusion molding (manufactured by Elf Atochem, trade name PEBAX7033SA01). The blank is formed into an airbag by a biaxial stretch blow forming process. The outer diameter of the straight pipe section of the airbag is 3.0 millimeters, and the inner diameter of the connecting part with the anti-displacement device is 0.95 millimeters.

[0104] The inner tube (inner diameter 0.42 mm, outer diameter 0.56 mm) and outer tube (inner diameter 0.71 mm, outer diameter 0.88 mm) were made of extrusion polyamide elastomer (manufactured by Elf Atochem, product name PEBAX7233SA01).

[0105] Polyamide elastomer (manufactured by Elf Atochem, trade name PEBAX7033SA01) is used for extrusion molding as a material to make a tubular anti-displacement device (inner diameter 0.65 mm, outer diameter 0.79 mm) on the far side of the airbag.

[0106] Polyamide elastomer (manufactured by ...

example 2

[0111] The prepared sample is the same as Example 1 except that the outer tube is used as the anti-displacement device on the proximal side of the airbag.

example 3

[0113] A sample was prepared, wherein the outer diameter of the part that stretched into the cone section at the far end of the air bag as the anti-displacement device at the far end of the air bag increased to 1.20 millimeters, and the anti-displacement device was like the tubular element in example 1; The outer diameter of the portion of the end-side anti-displacement device that protrudes into the cone section at the proximal end of the airbag is also increased to 1.20 mm. This anti-displacement device is like the tubular element in Example 1. In addition, the inner diameter of the connection between the airbag and the two anti-displacement devices is adjusted to 1.25 mm. The rest are the same as the sample of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com