Mixing dynamic gate type machine with electrical driving tires for hoisting ship

A hybrid electric and crane technology, applied in the direction of cranes, trolley cranes, load suspension components, etc., can solve the problems of serious emission pollution, large energy consumption, and insufficient flexibility in steering and driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

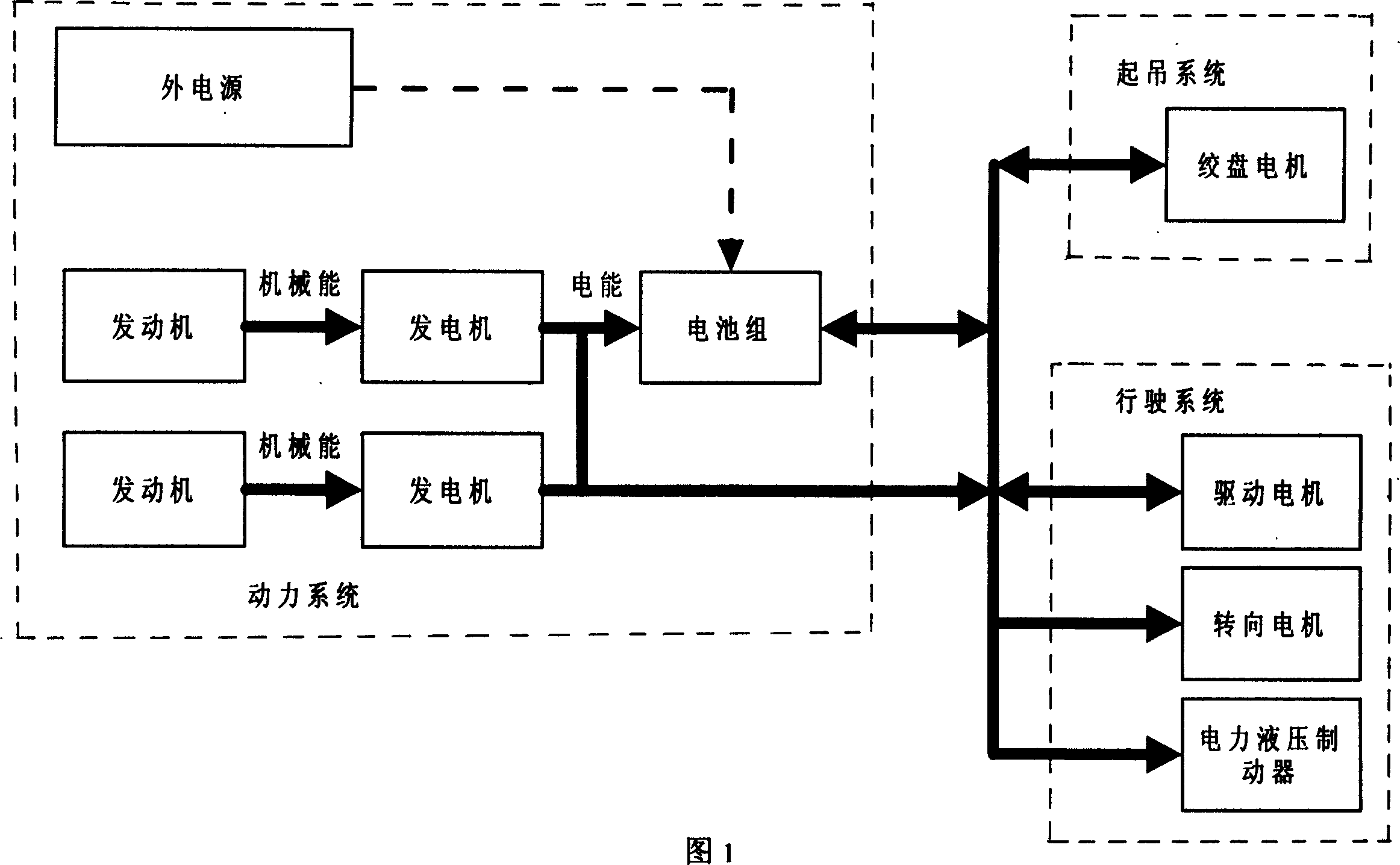

[0021] As shown in Figure 1, the hybrid electric tire gantry crane is mainly composed of a steel structure frame, a lifting system, a power system, a driving system, and a control system. The driving system is composed of a driving system, a braking system, and a steering system. The steel structure frame is the skeleton of the crane, the lifting system is used for the lifting operation of the crane, the hybrid power system provides energy and power for the crane, the drive system assembly enables the crane to realize the self-driving function, and the brake system assembly Realize the form braking function, the steering system assembly realizes the steering function for the crane, there are three steering modes to choose from (such as Figure 8 , Figure 9 , Figure 10 shown), the control system is the control center of the crane.

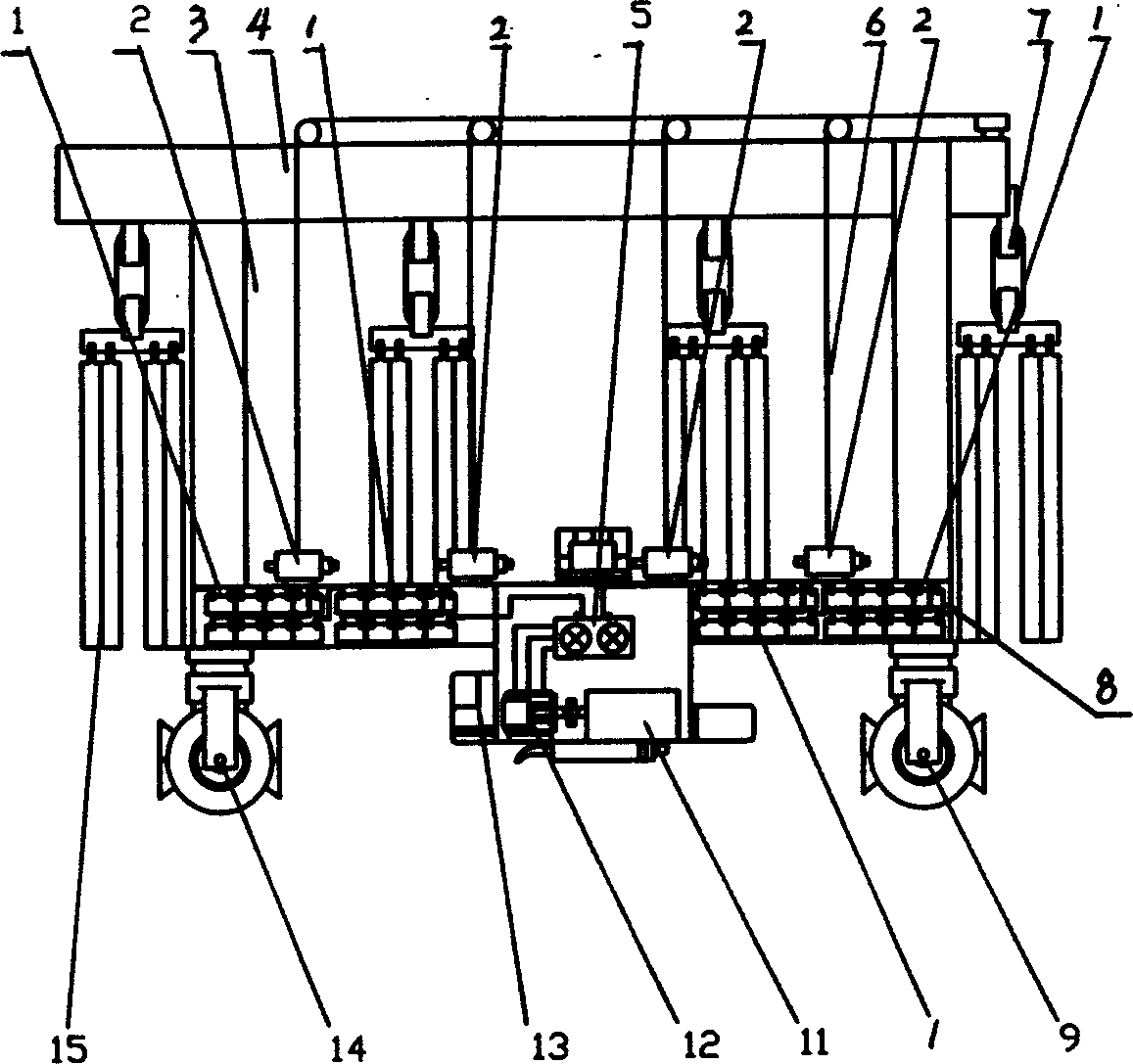

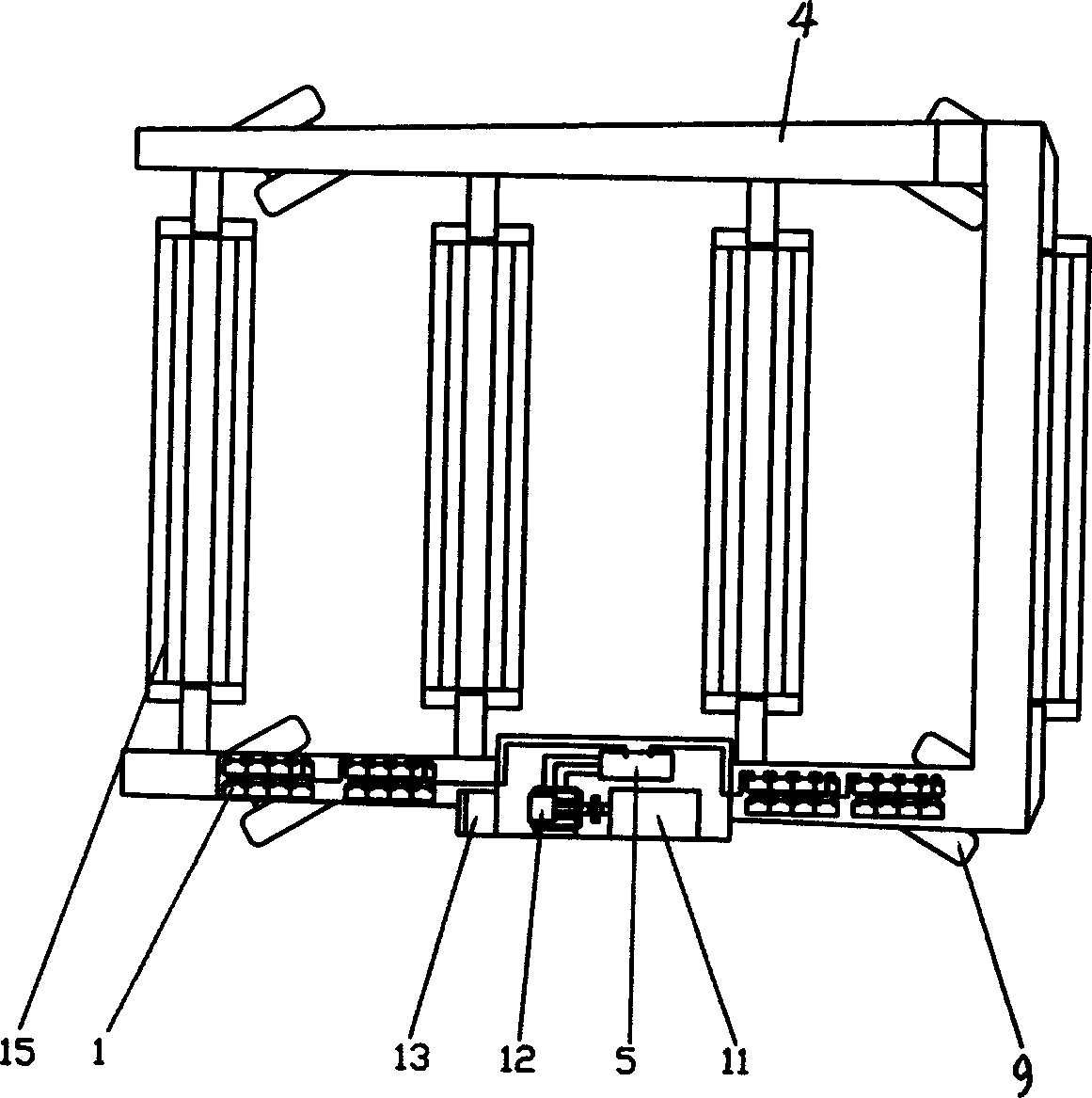

[0022] Such as figure 2 , image 3 , Figure 4 Shown, steel frame is prior art, and steel frame is made of column 3, upper bracket 4, lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com