Low temp rising high precision boosting regulated supply

A stabilized power supply and high-precision technology, applied in the direction of conversion equipment without intermediate conversion to AC, can solve the problems of labor-consuming and time-consuming operation costs, frequent traffic jams, poor construction safety, etc., and achieve improved comprehensive performance and long working hours , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

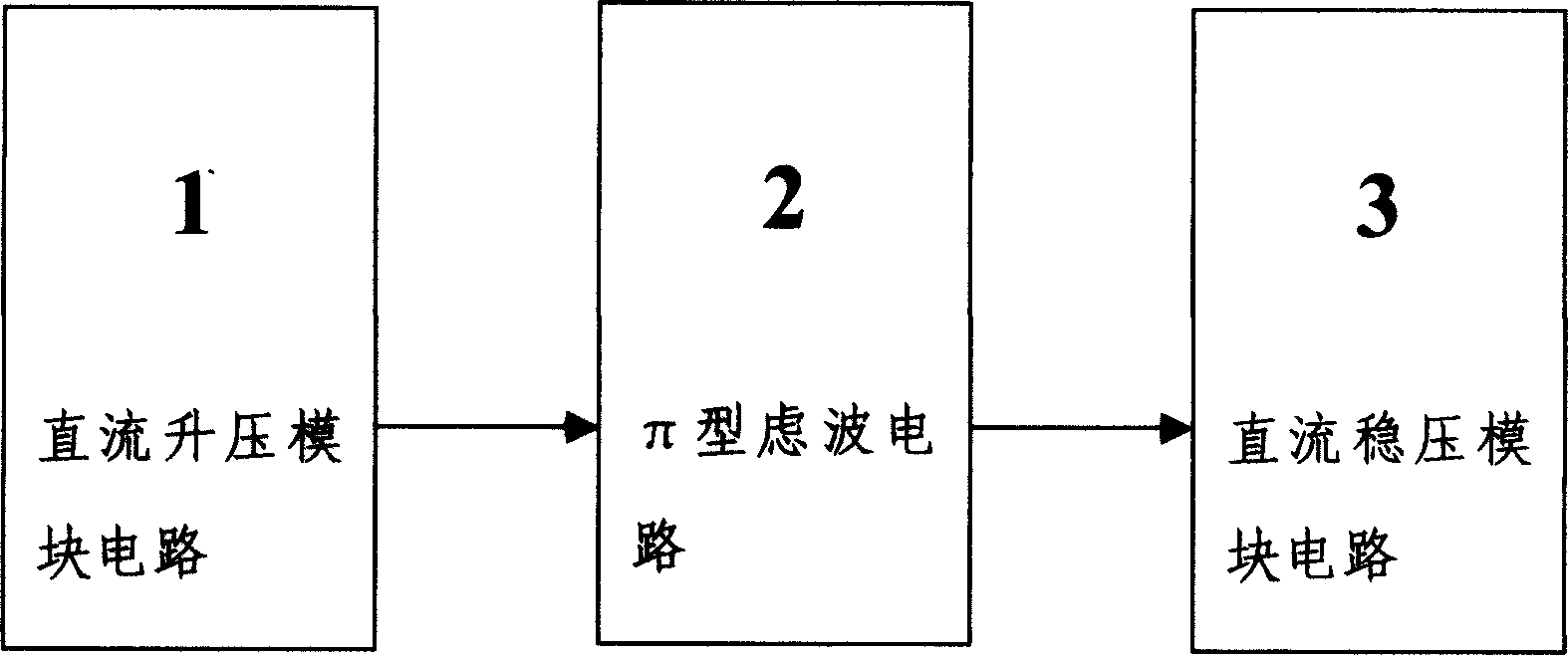

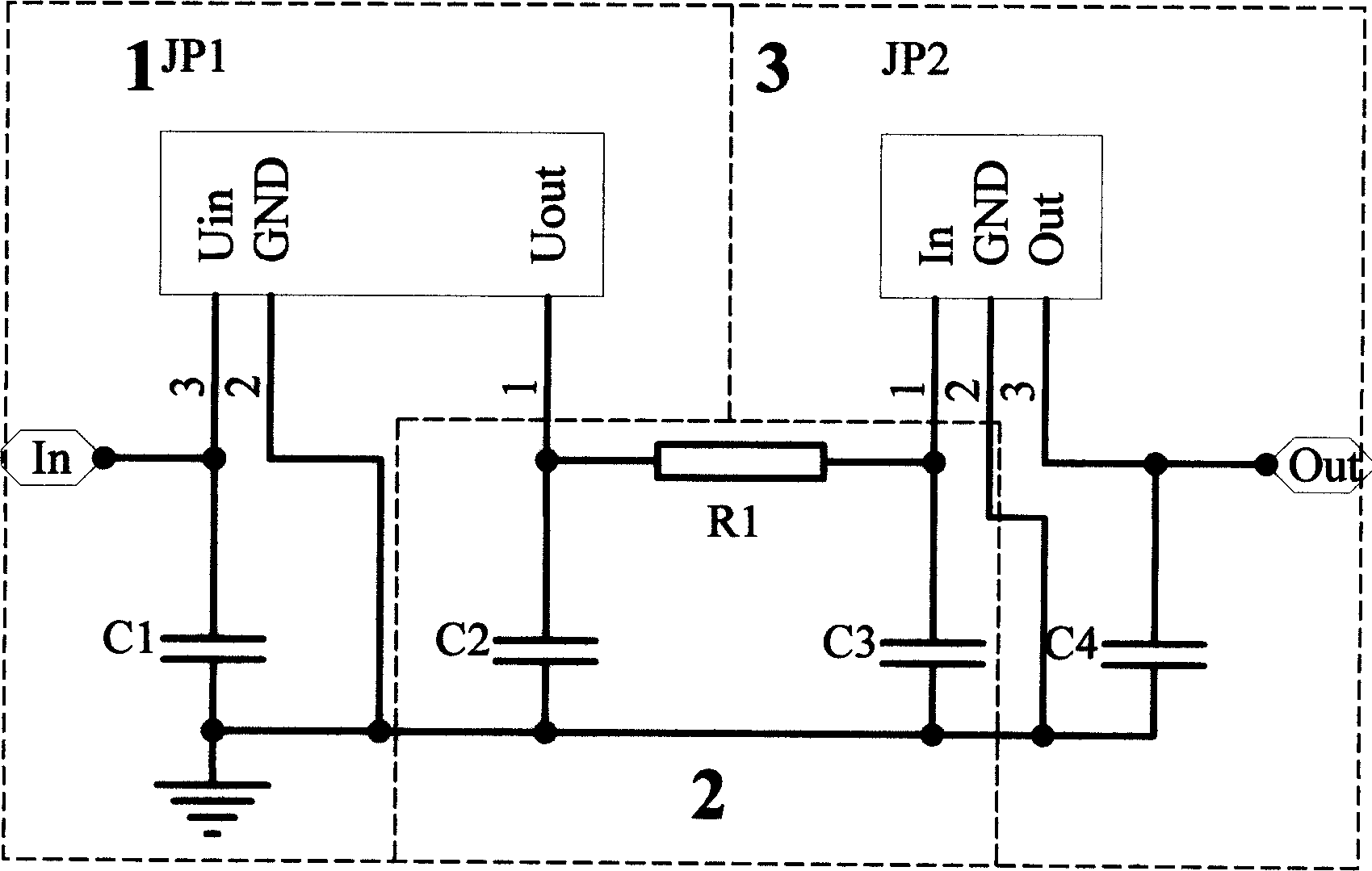

[0011] exist Figure 1 Among them, the present invention is composed of a DC boost module circuit (1), a π-type filter circuit (2), and a DC voltage stabilizing module circuit (3); the DC boost module circuit (1) is a low DC voltage input, high DC Voltage output voltage stabilizing circuit, the output high DC voltage is filtered by the π-type filter circuit (2) and input to the DC voltage stabilizing module circuit (3), and the required stabilizing voltage is output by it, so as to use only two sections of 1.5 The V battery makes it provide long-time, low-temperature drift, and high precision, which is in line with the purpose of detecting the working voltage of the oriented emission probe.

[0012] exist Figure II In the shown embodiment, the DC step-up module circuit (1) is composed of a DC step-up integrated circuit JP1 and a capacitor C1, and pin 3 of the integrated circuit JP1 is a 3V voltage input terminal. Connect capacitor C1 in parallel, the other end of capacitor C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com