High pressure pump system for supplying a cryogenic fluid from a storage tank

A low-temperature fluid and low-temperature system technology, applied in the direction of charging system, pump, pump control, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

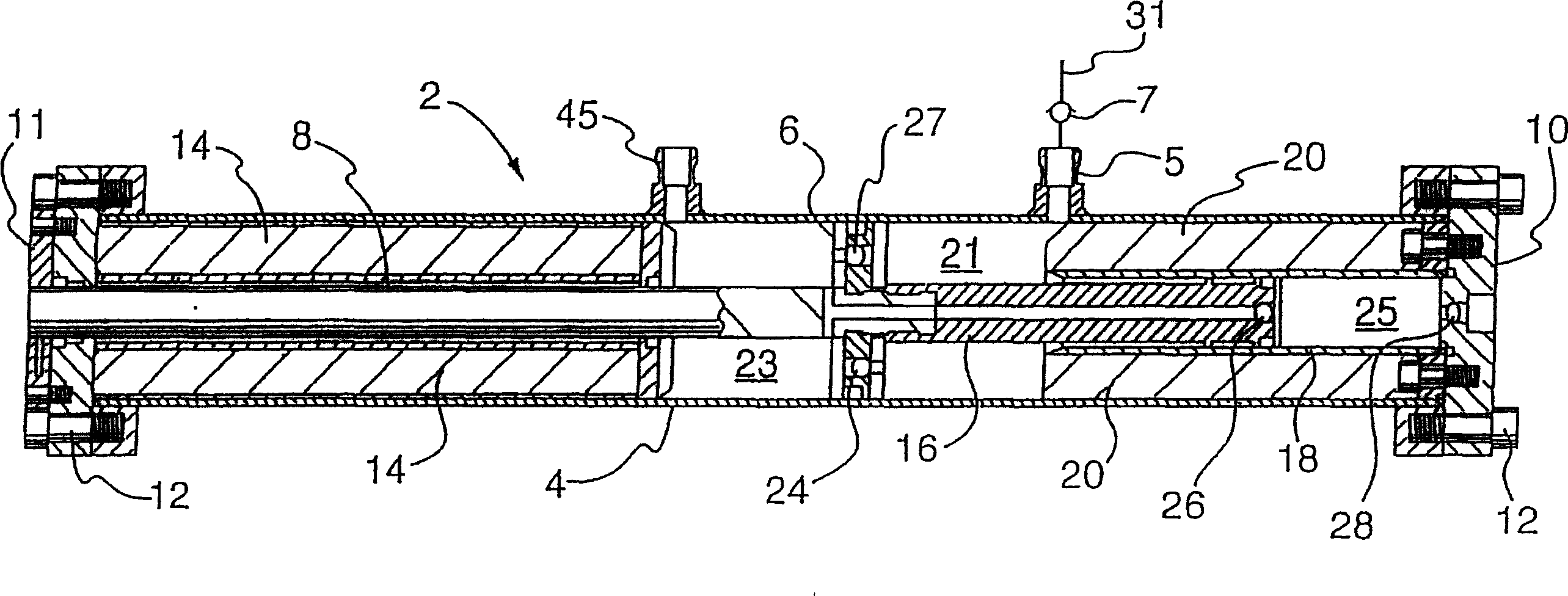

Method used

Image

Examples

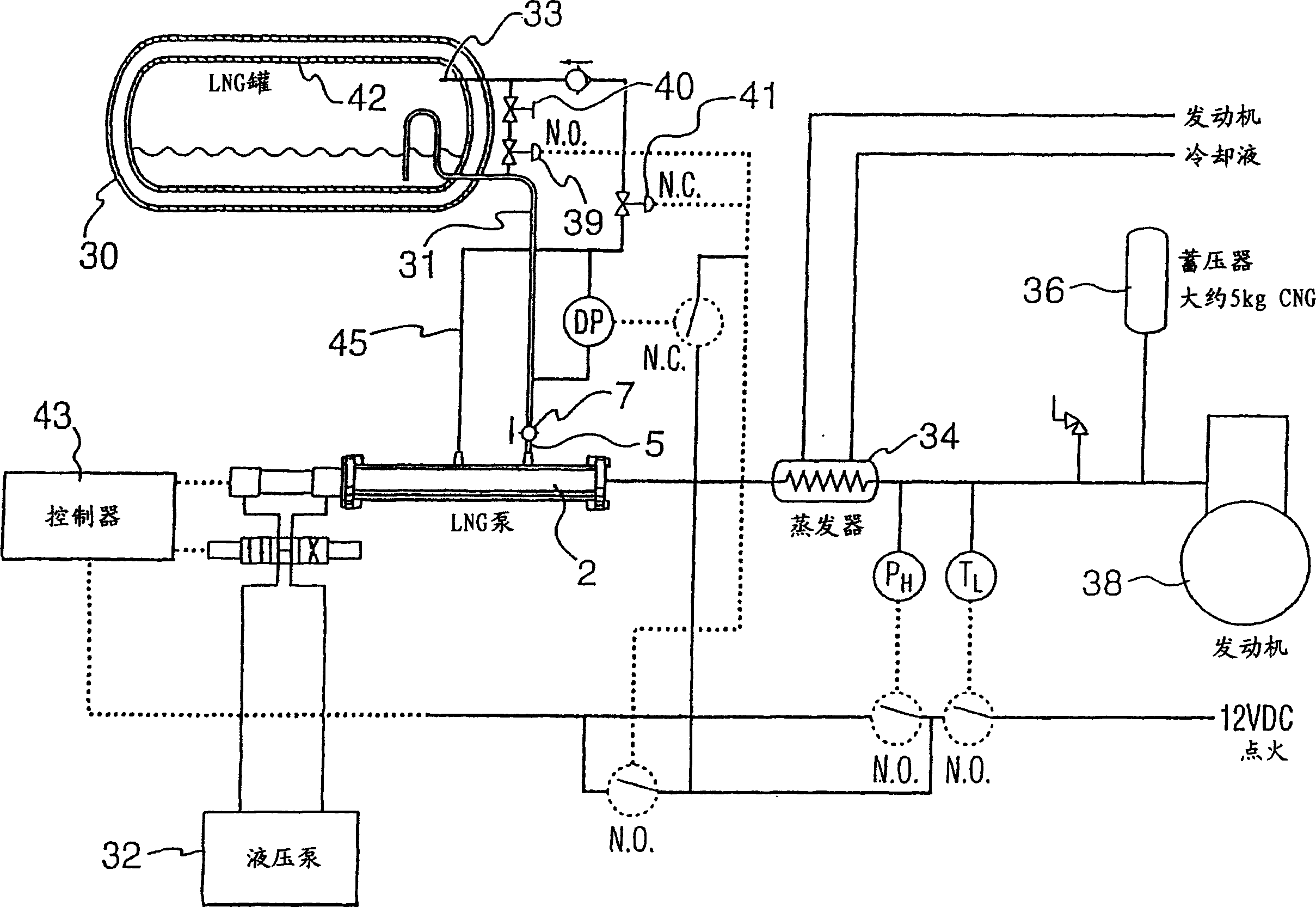

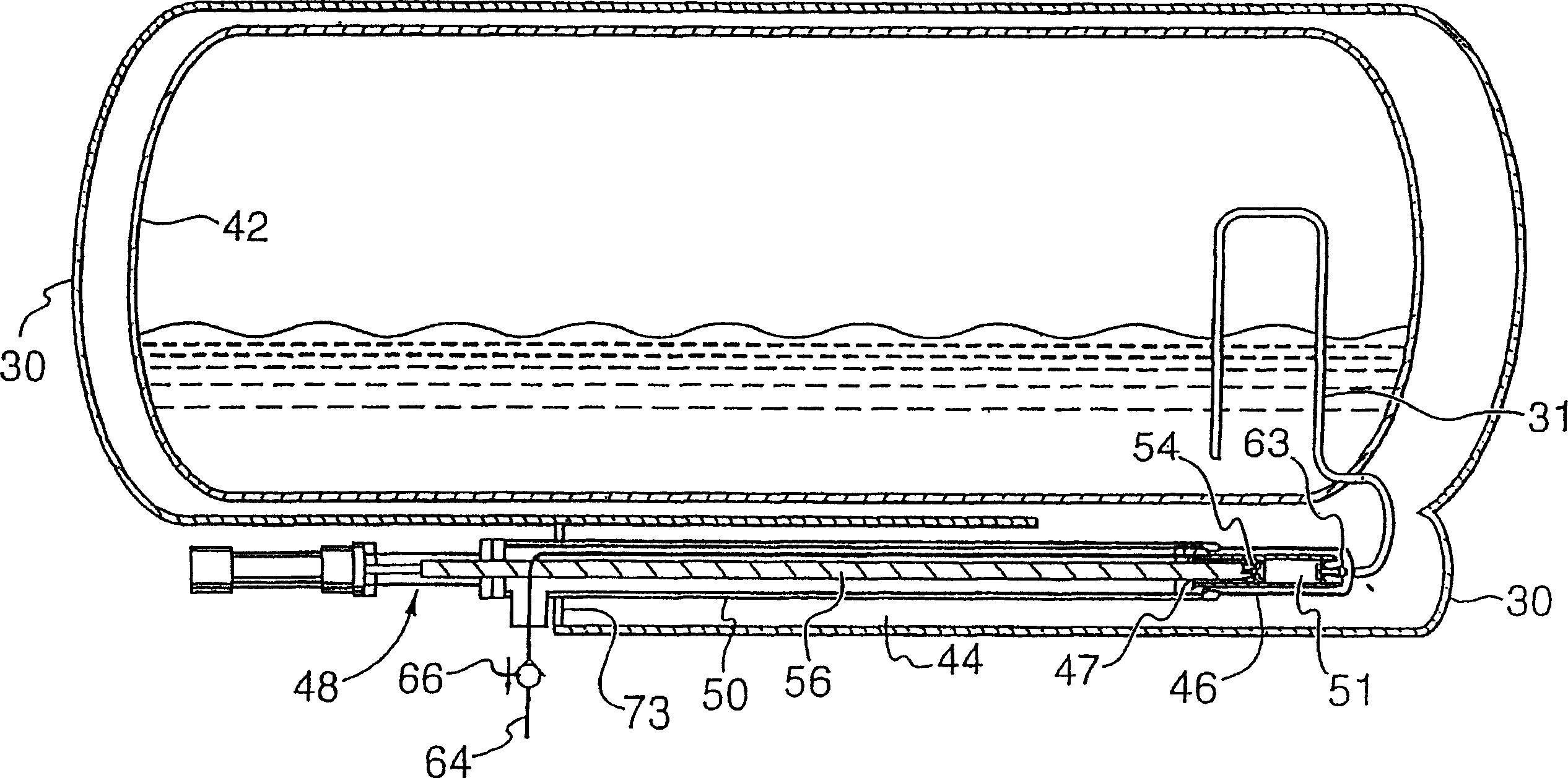

Embodiment Construction

[0072] Engines burning natural gas can be roughly divided into two categories, namely those with a low-pressure fuel system and those with a high-pressure fuel system. A low pressure fuel system is defined as an engine fuel system that operates at a fuel pressure lower than the minimum operating pressure of the storage tank. In this type of low pressure system, no fuel pump is required, and the storage tank has a vapor line to remove vapor from the storage tank and a liquid line to remove liquid from the storage tank. Each line is controlled by a corresponding valve which in turn is controlled by at least one pressure sensor. The engine normally receives fuel through the liquid line except when the tank pressure exceeds a certain pressure, say about 60 psig (516kPa), where the vapor line opens, releasing some vapors to the engine , which reduces the pressure in the storage tank, ensuring a longer holding time. This is a simple system that ensures that the tank pressure remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com