Ethylene-vinyl acetates film for crosslink foaming , parts of shoes using the same and making method thereof

A technology of vinyl acetate and vinyl acetate, which is applied in applications, footwear, clothing, etc., can solve the problems of functional differentiation, narrow selection range, and difficulty in realizing the characteristics of material image characteristics in the forming process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

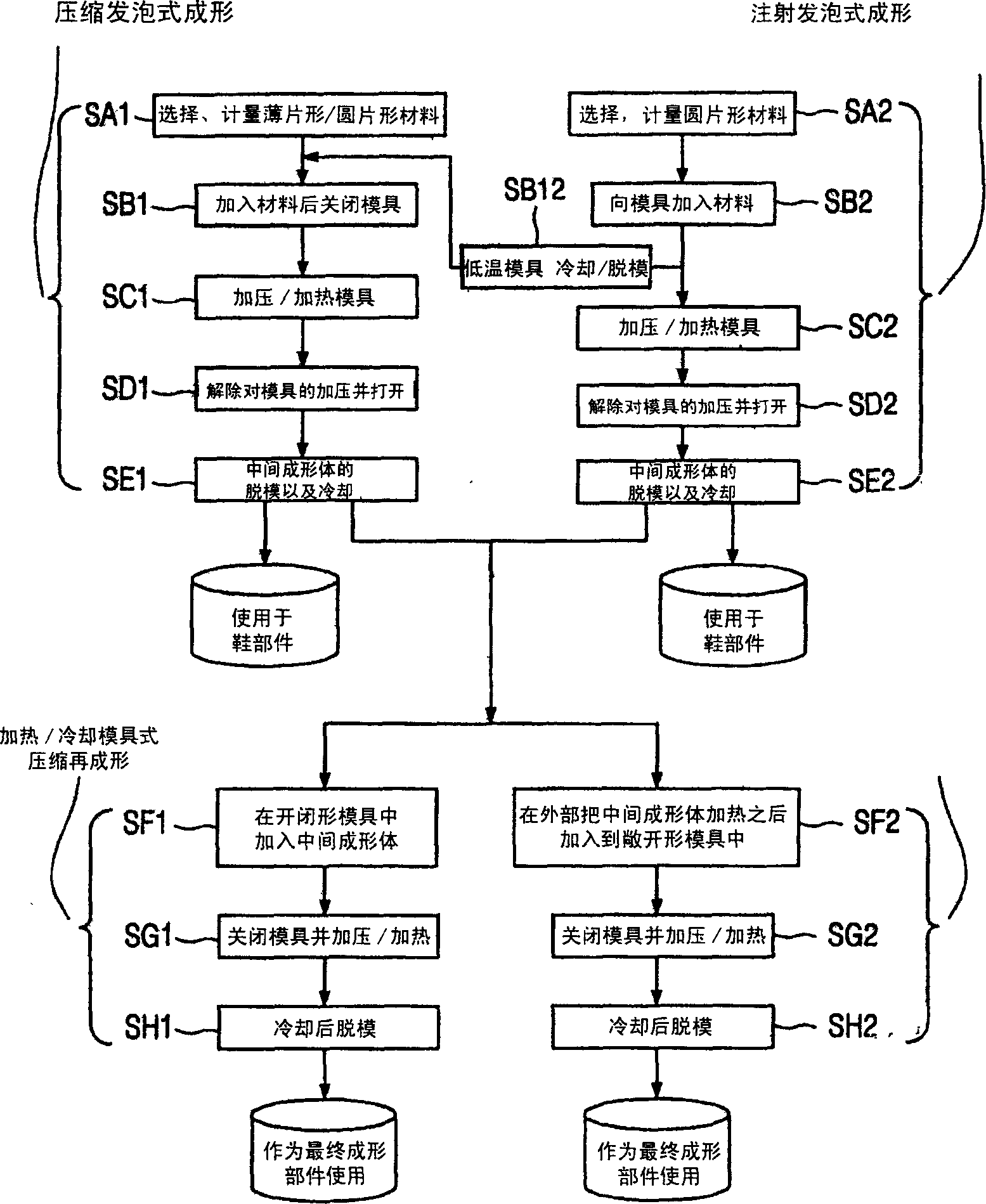

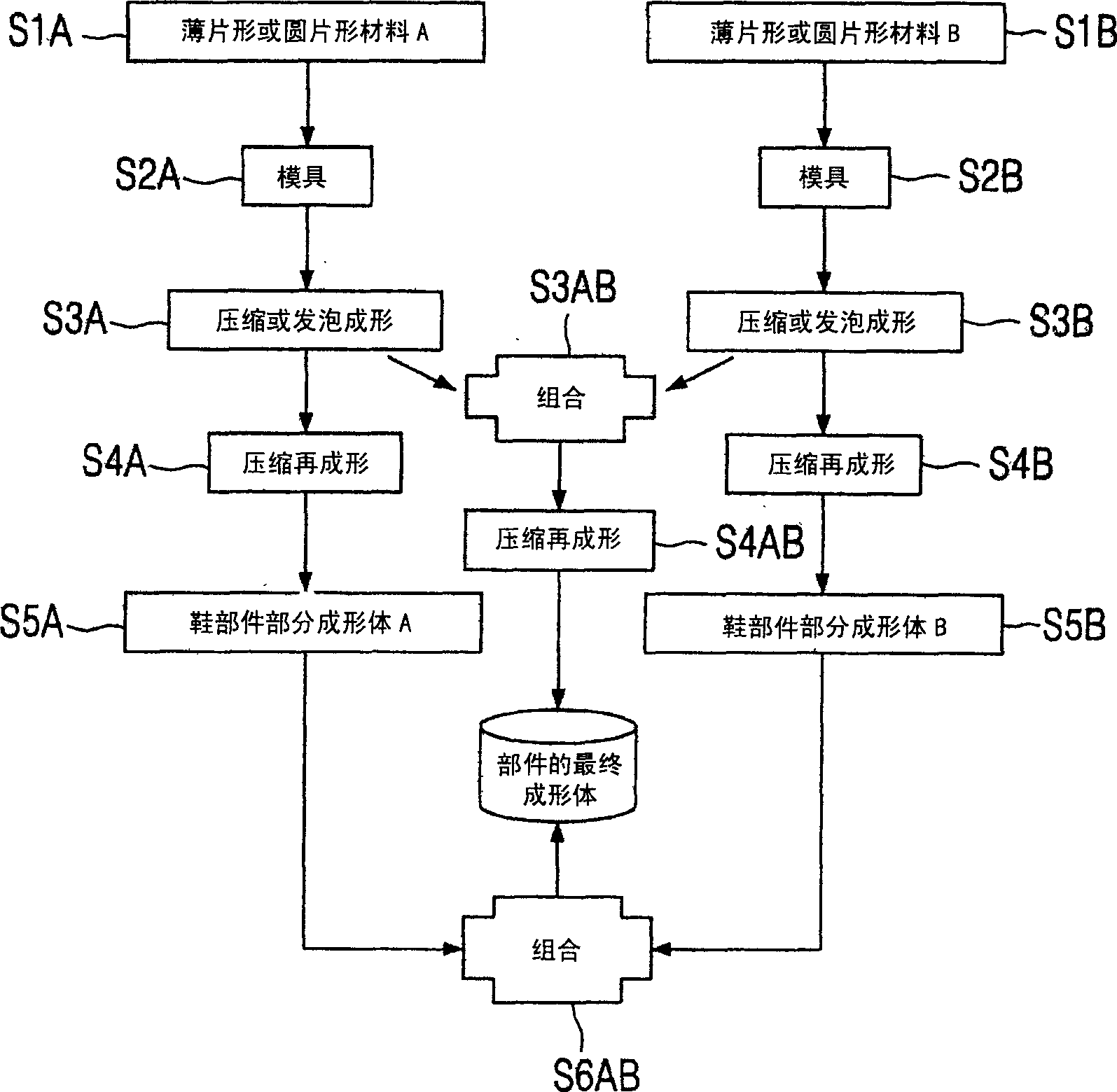

Method used

Image

Examples

example 1

[0115] EVA base compound (melt index 3.0g / 10min, VA content 22~23wt%); 100phr

[0116] The purity of DCP as a crosslinking agent is 98%; 0.66phr

[0117] As blowing agent JTR-M; 1phr

[0118] Stearic acid; 1phr

[0119] ZnO; 1phr

[0120] 75Ca-St; 1phr

[0121] MgCO 3 ; 8phr

[0122] TiO 2 ; 1phr

example 2

[0124] EVA base compound (melt index 3.0g / 10min, VA content 22~23wt%); 50phr

[0125] Ethylene-butene copolymer 1 (Tafmer940); 15phr

[0126] Ethylene-butene copolymer 2 (Tafmer610); 30phr

[0127] Isoprene rubber; 5phr

[0128] The purity of DCP as a crosslinking agent is 98%; 0.78phr

[0129] ACDC as blowing agent; 2phr

[0130] TAC as a blowing agent; 0.2phr

[0131] Stearic acid; 1phr

[0132] ZnO; 3phr

[0133] CaCO 3 ; 5phr

[0134] As pigment TiO 2 ; 4.5phr

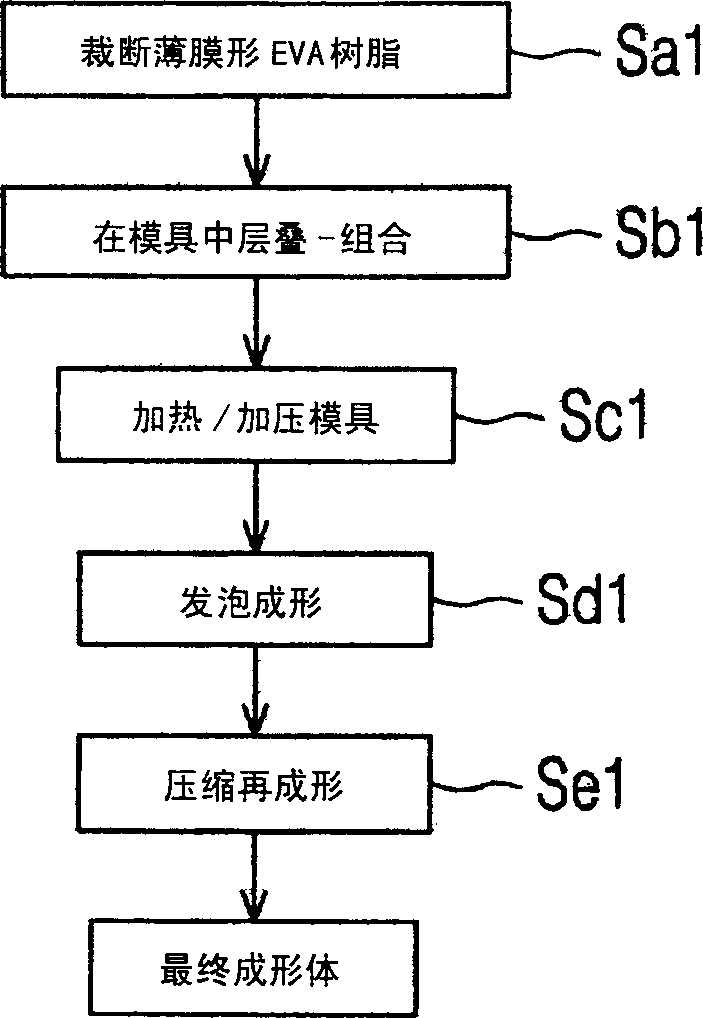

[0135] An example of the cross-linked foaming EVA film of the present invention will be described below. The cross-linked foaming EVA film of the present invention can be manufactured most effectively through a thin calendering process, and can be especially connected with the above The material is manufactured at the end of the manufacturing process of the conventional cross-linked foamed EVA-based sheet or disc-shaped material.

[0136] Use a Banbury mixer that can effectively consider the different characteristics o...

Embodiment 1

[0163] When preparing the EVA base compound material film, make a film with the same mixing ratio of the main component and the auxiliary component, and prepare the following film-shaped EVA base compound material with a thickness of 0.5 mm. Unless otherwise specified, the film material is the EVA base compound, which is the following material.

[0164] W1: White, hardness shore C50+ / -2 after one compression foaming process or after re-compression molding

[0165] Cut the above-mentioned W1 material according to the reduced shape of each part of the designed shoe component. Then, the above-mentioned materials, such as 10 cut-off W1 films, are superimposed into the mold and filled up.

[0166] Then, through the various steps described above, that is, if briefly described, the molded body obtained after the compression and foaming step is cooled, and then the compression and remolding step is not performed twice, and the part formed due to the structure of the mold during the moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com