Machine carried electric traction coal-mining machine with short main body

A coal mining machine and electric traction technology, which is applied in the direction of cutting machinery, earth drilling, driving devices, etc., can solve the problems of small explosion-proof box on the machine, the control signal is easily interfered by the outside world, and the low-speed performance of electric traction is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

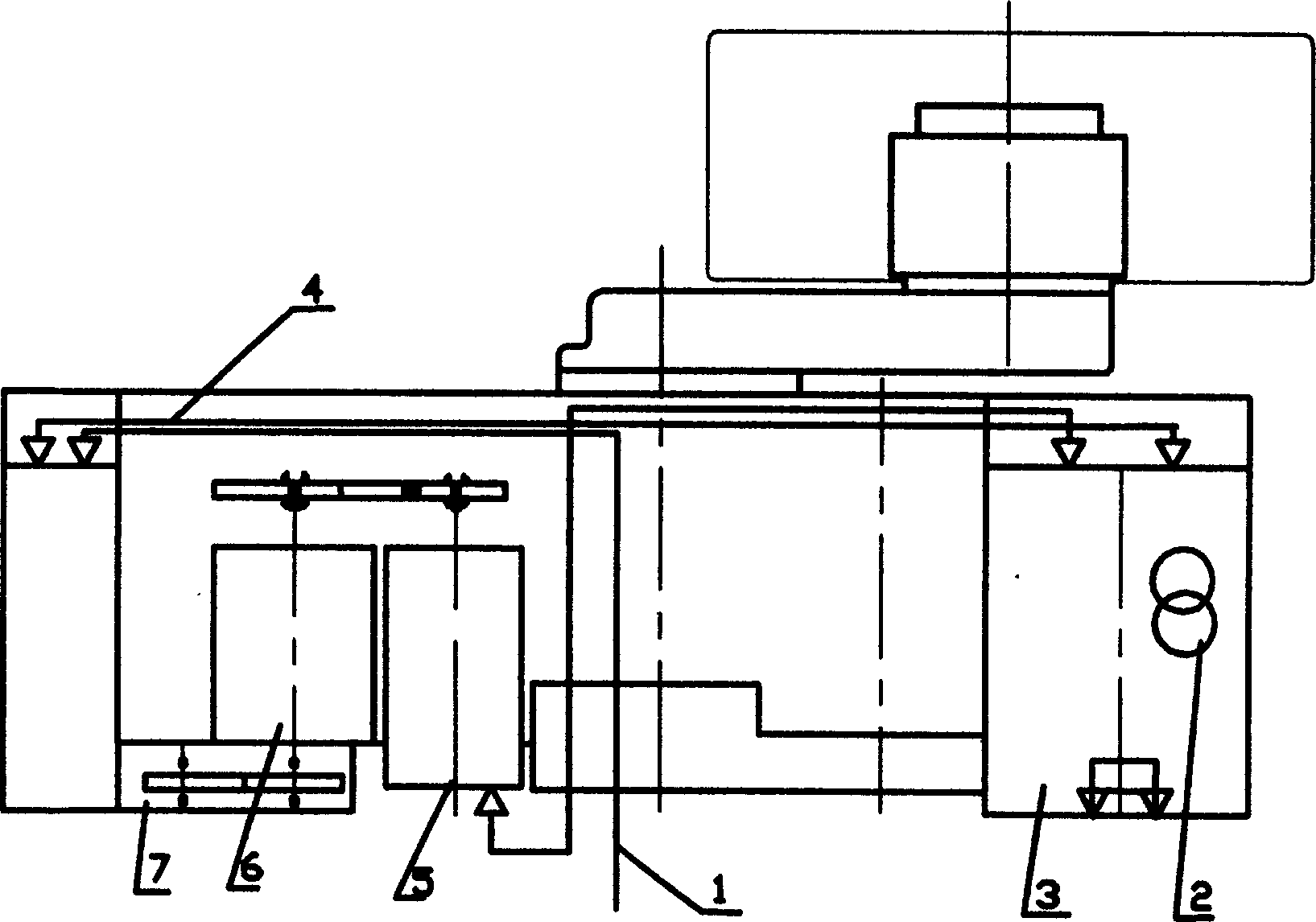

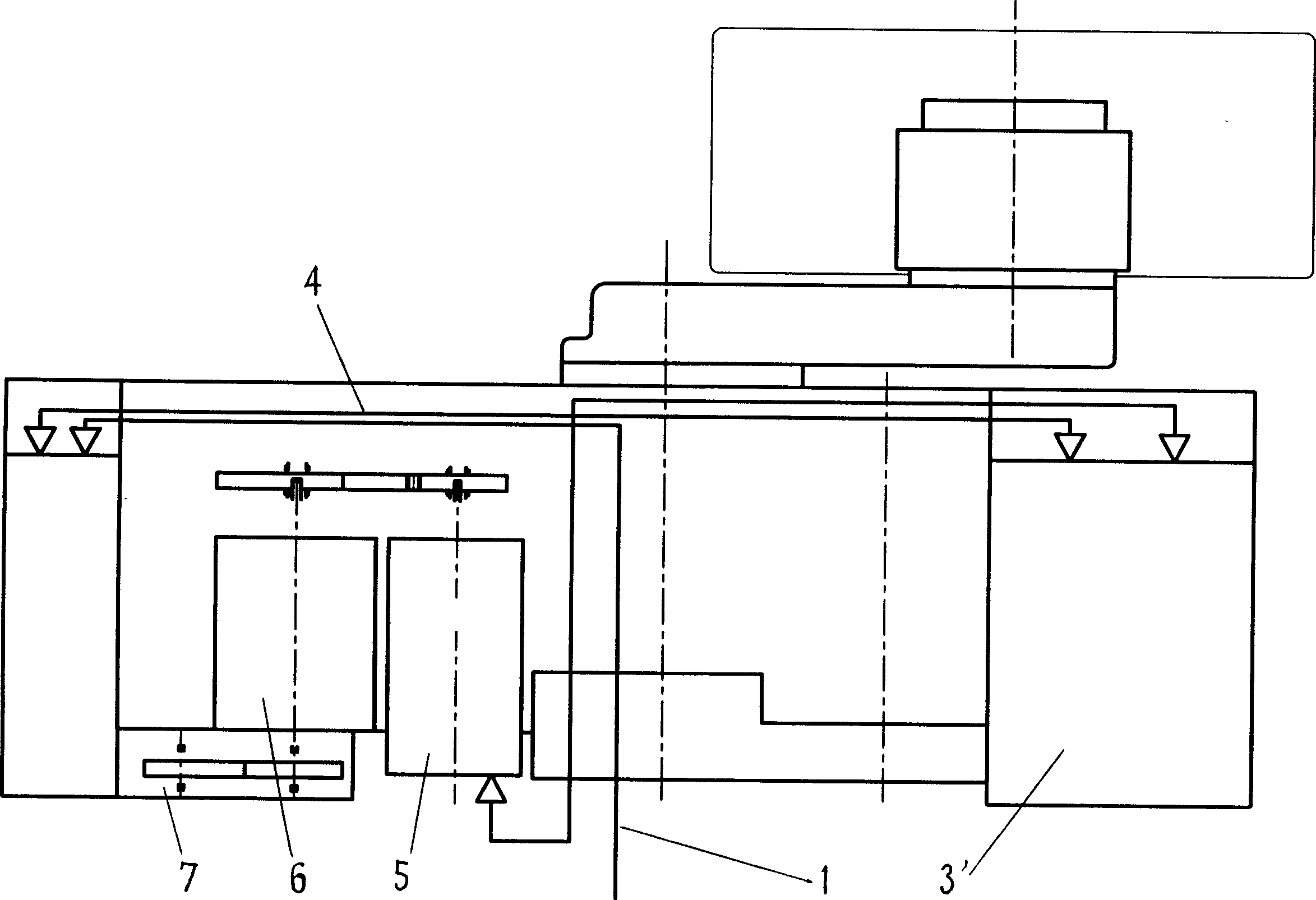

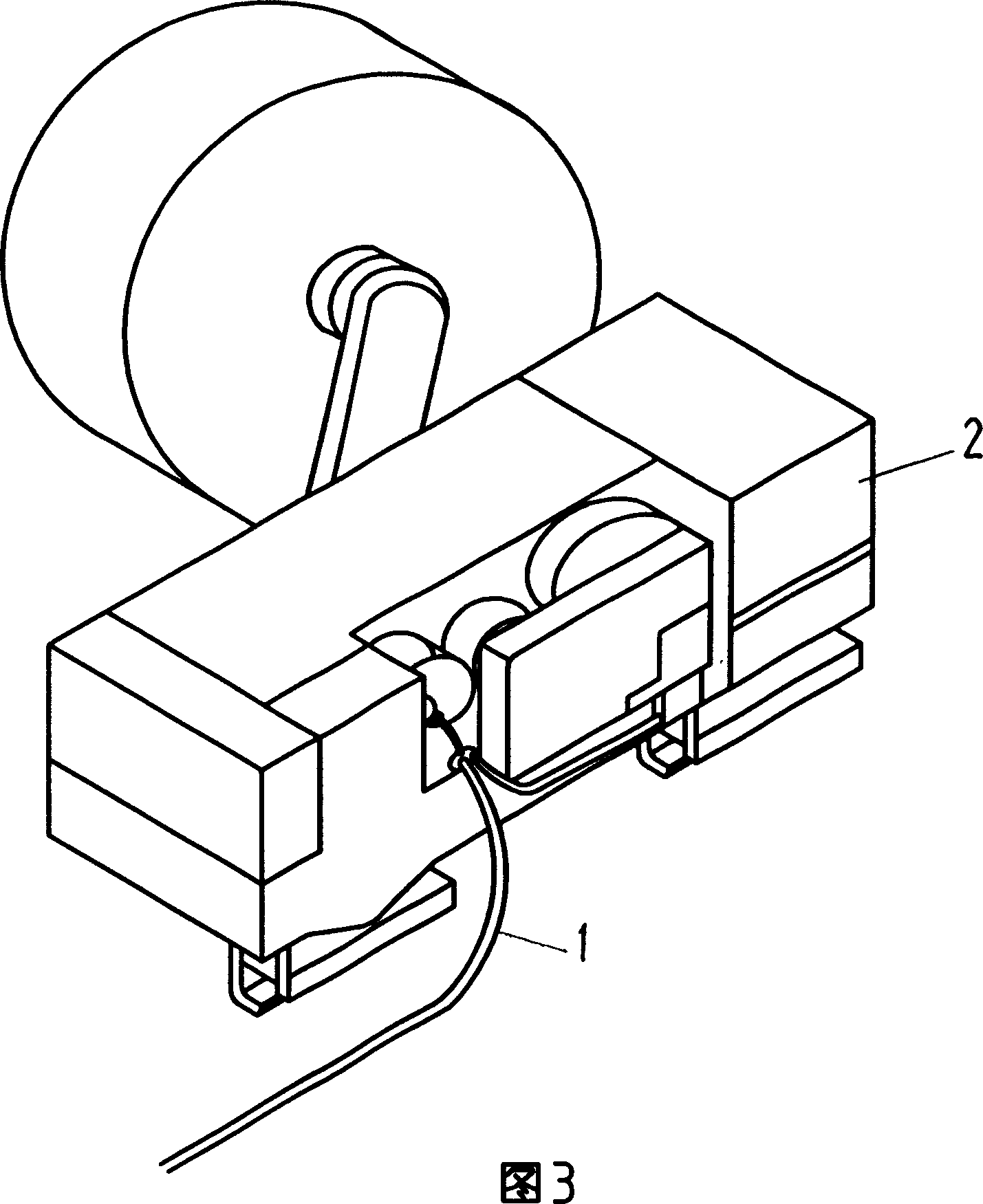

[0014] refer to figure 1 , Fig. 3, the airborne electric traction shearer with short fuselage includes power supply cable 1, airborne transformer 2, low-power electric speed control device 3, internal cable 4, traction motor 5, traction reduction box 6 and travel box 7 The power supply cable 1 is connected to the power supply and the onboard transformer 2. The onboard transformer 2 can be a compact structure. The transformer 2 installed on the fuselage is connected to the low-voltage electrical speed regulating device through the cable 4, and the power supply voltage (such as 1140V) is reduced. Below the working voltage (generally 500V) of the low-voltage electrical speed regulating device 3, the low-voltage electric speed regulating device 3 can be a low-voltage AC frequency conversion speed regulating device, a low-voltage switched reluctance speed regulating device or a low-voltage DC speed regulating The speed device is connected with the traction motor 5 through the cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com