Capacitor arrangement

A capacitor structure, capacitor technology, applied in instruments, circuits, electrical components, etc., can solve the problems of insufficient pixel aperture ratio, decreased contrast, uncompetitiveness, etc., and achieve overall improvement in contrast deficiency, increased aperture ratio, and competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

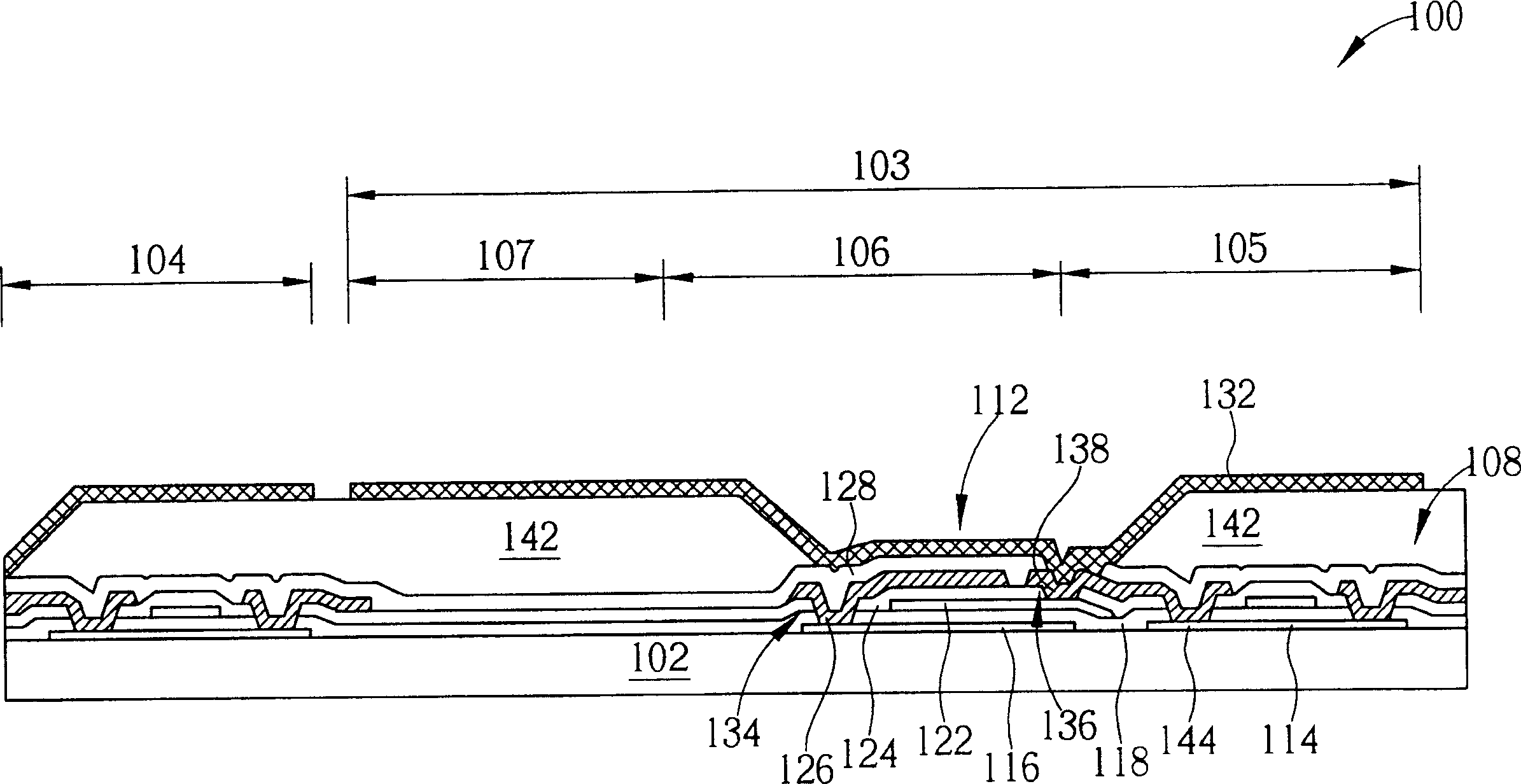

[0034] Please refer to image 3 , image 3 It is a schematic structural diagram of a thin film transistor liquid crystal display panel 100 of the present invention. Such as image 3 As shown, the thin film transistor liquid crystal display panel 100 of the present invention has a substrate 102. The substrate 102 is an insulating substrate made of a light-transmitting material, and is usually a glass substrate, a quartz substrate or a plastic substrate. The surface of the substrate 102 has a pixel array area 103 and a peripheral circuit area 104, and the pixel array area 103 also has a thin film transistor area 105 for setting a thin film transistor 108, and a capacitor area 106 for setting a storage capacitor 112 , and an opening area 107 . Since the gate 114 of the thin film transistor 108 is made of low temperature polysilicon material, the thin film transistor 107 is a low temperature polysilicon thin film transistor.

[0035] The storage capacitor 112 has a first condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com