Whirlpool dish for whirlpool compressor

A scroll compressor and scroll technology, which is applied to rotary piston machinery, rotary piston/oscillating piston pump components, mechanical equipment, etc. Increase the radius and other problems to achieve the effect of increasing space utilization, reducing the radius of gyration, and increasing the air intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

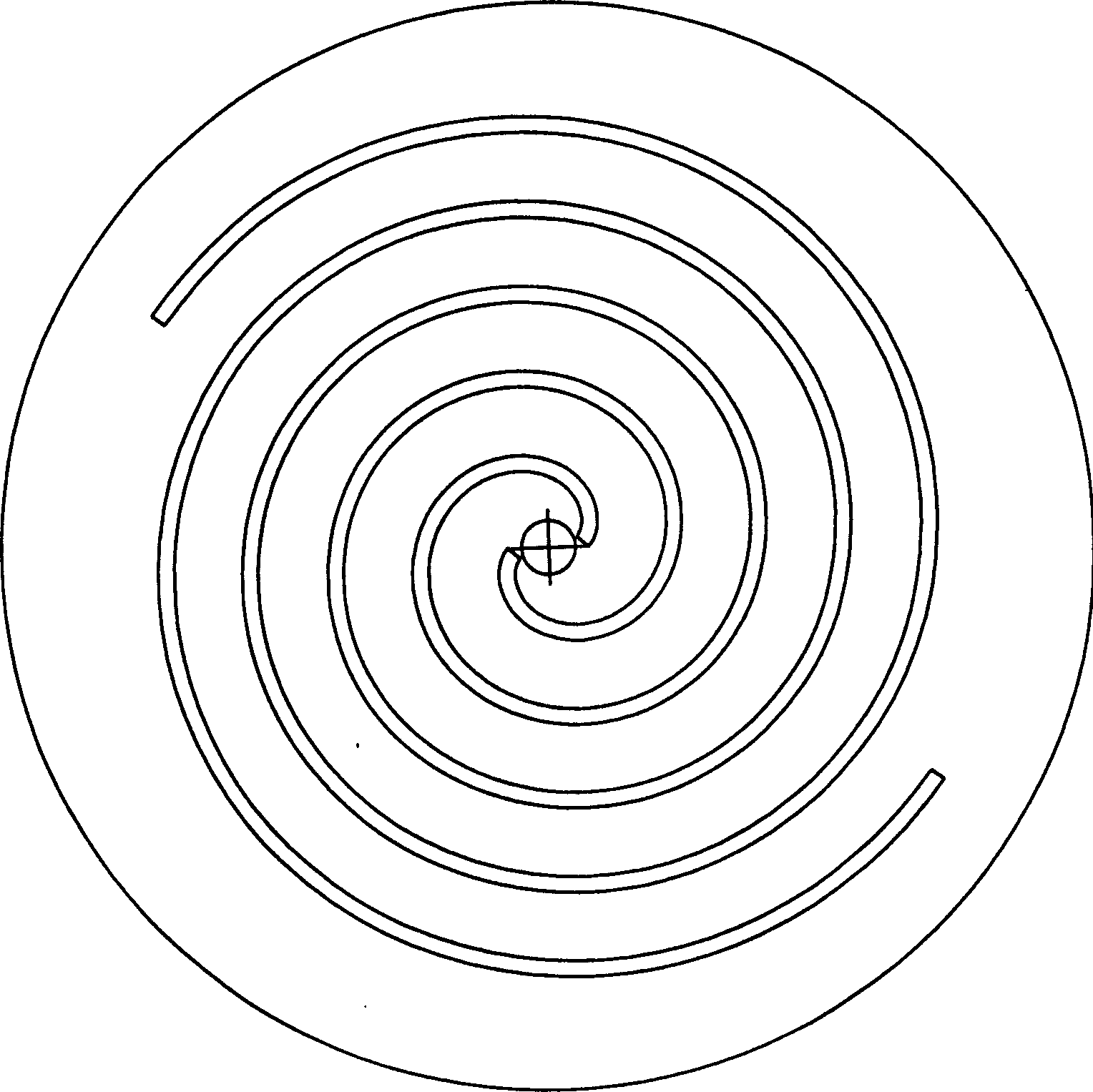

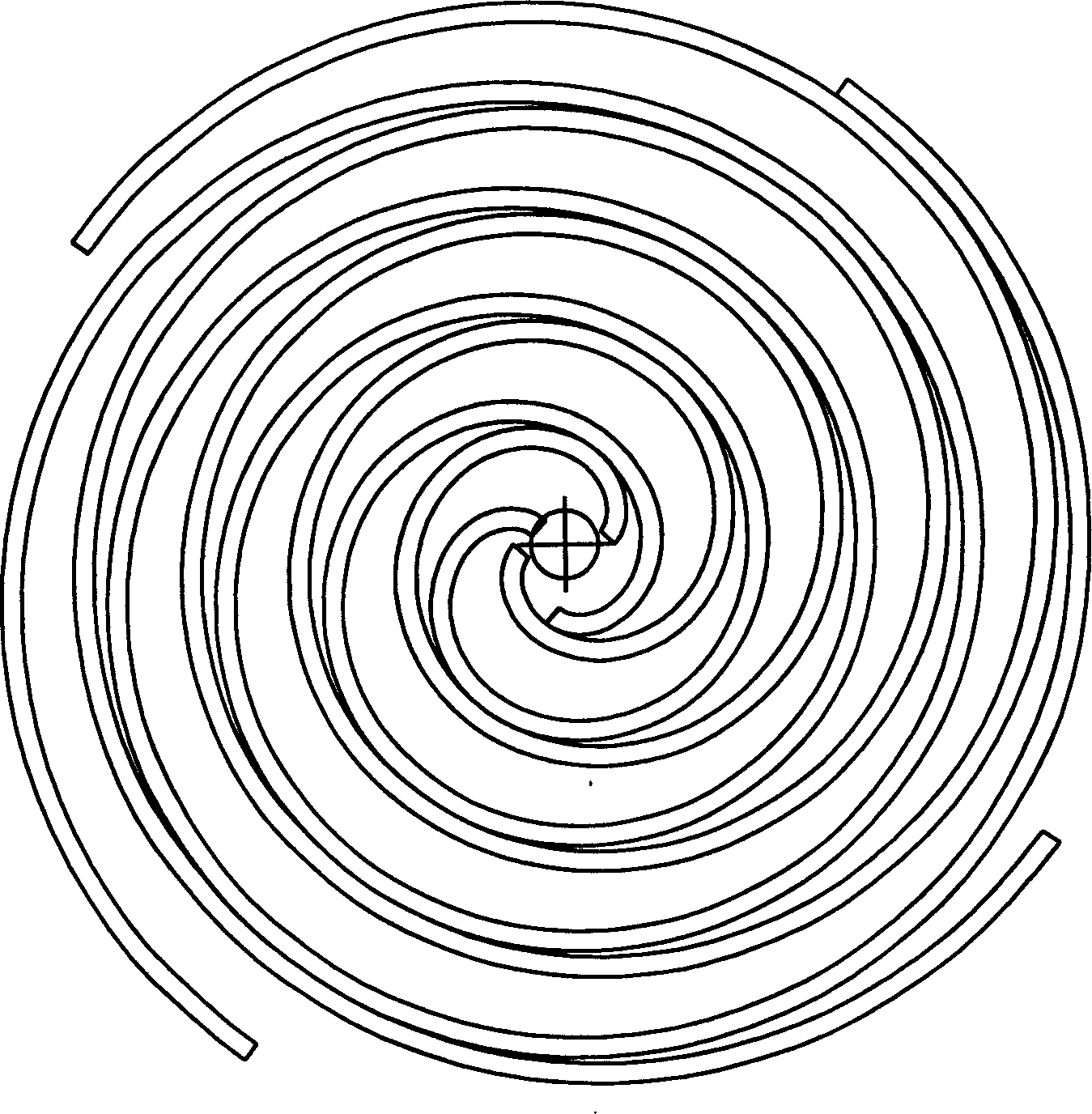

[0007] Such as figure 1 As shown, the scroll teeth extend out of the disk surface of the movable scroll and the fixed scroll respectively, and are respectively perpendicular to the disk surfaces of the movable scroll and the static scroll where they are located. There are two independent spiral teeth. Such as figure 2 As shown, when the compressor is working, the four scroll teeth mesh with each other to form four independent crescent-shaped compression chambers every week. The gas is divided into two paths from the air inlet and enters the suction chamber for compression. Air vents out of the machine. Such as figure 1 As shown, two scroll-shaped teeth are established at relative 180° positions on the movable scroll and the fixed scroll. Compared with the single-swirl-shaped teeth, the base circle radius of the involute increases, and The angle of occurrence decreases, the number of intake chambers increases to two, the volume change of a single chamber increases, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com