Capacitor type semiconductor pressure sensor

A pressure sensor and semiconductor technology, which is applied in the direction of semiconductor devices, fluid pressure measurement using capacitance changes, electric solid devices, etc., can solve the problem of high cost, reduce processing costs, meet market price requirements, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

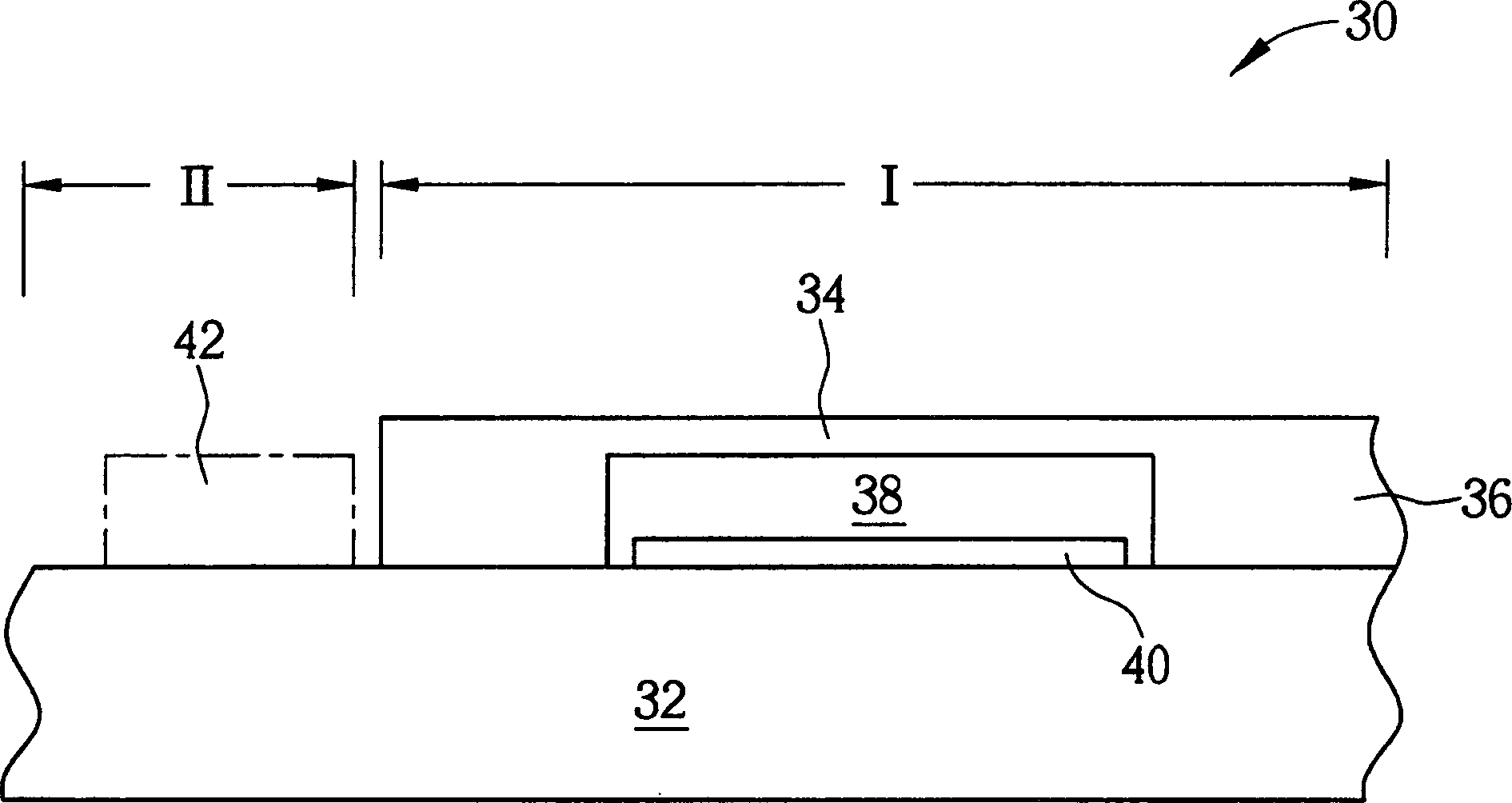

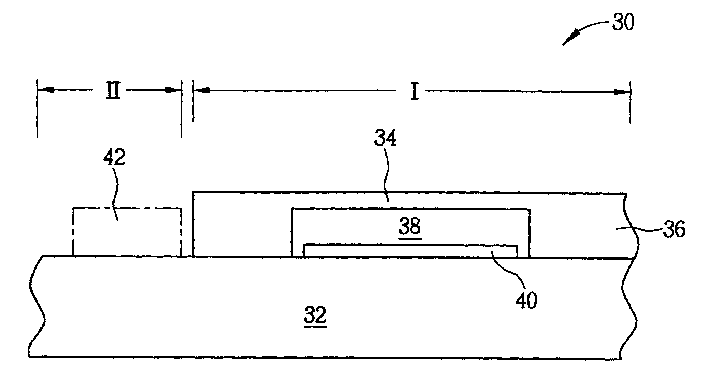

[0012] Please refer to figure 2 , figure 2 It is a schematic cross-sectional view of the capacitive semiconductor pressure sensor 30 of the present invention. Such as figure 2 As shown, the pressure sensor 30 of the present invention mainly includes a non-single crystal silicon substrate 32; a conductive and movable polysilicon diaphragm 34; a polysilicon support member (supporter) 36, which is located on the non-single crystal silicon substrate 32 for fixing The two ends of the polysilicon diaphragm 34 form a closed recess 38 between the polysilicon diaphragm 34 and the non-single crystal silicon substrate 32; a fixed electrode 40 is arranged in the non-single crystal silicon substrate 32 below the polysilicon diaphragm 34, and the polysilicon diaphragm 34 and the fixed electrode 40 are respectively used as the upper and lower electrodes of the plate capacitance of the pressure sensor 30; and a control circuit, such as a thin film transistor (thinfilm transistor, TFT) co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com