Burner for synthesis gas

A technology of burners and combustion chambers, which is applied in the direction of gas fuel burners, burners, combustion chambers, etc., and can solve the problems of inability to maintain effective injection of natural gas, high backfire risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

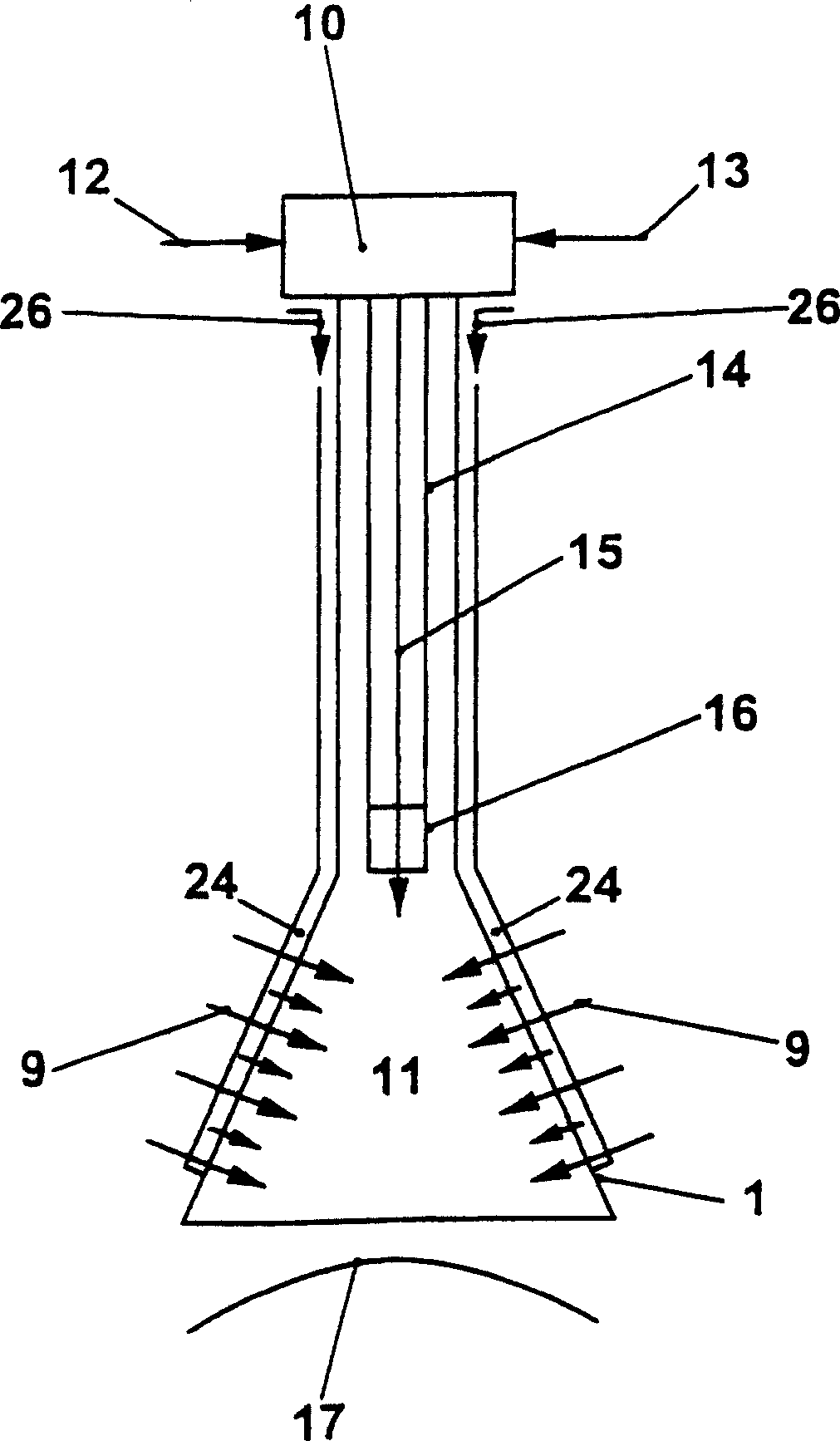

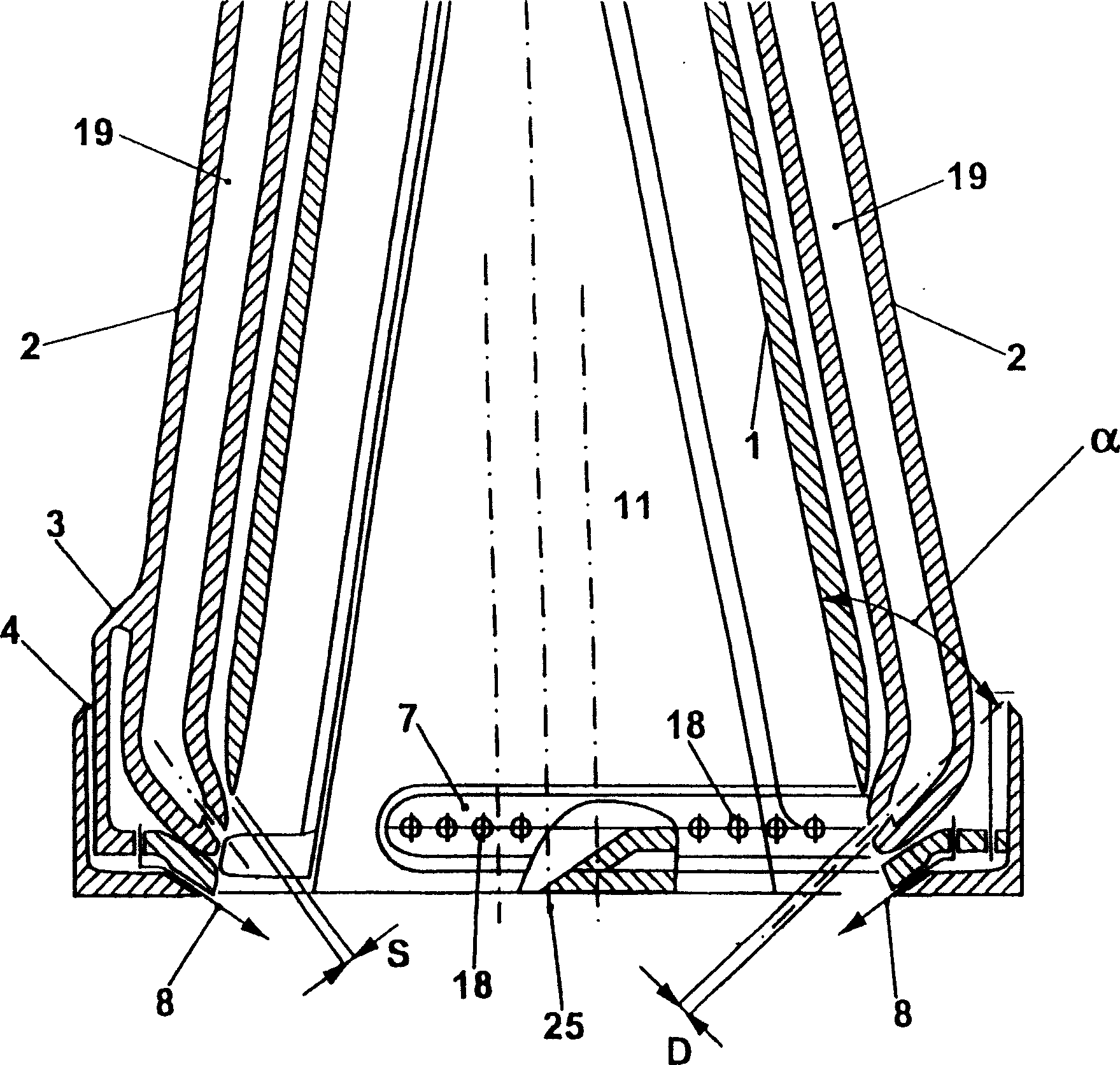

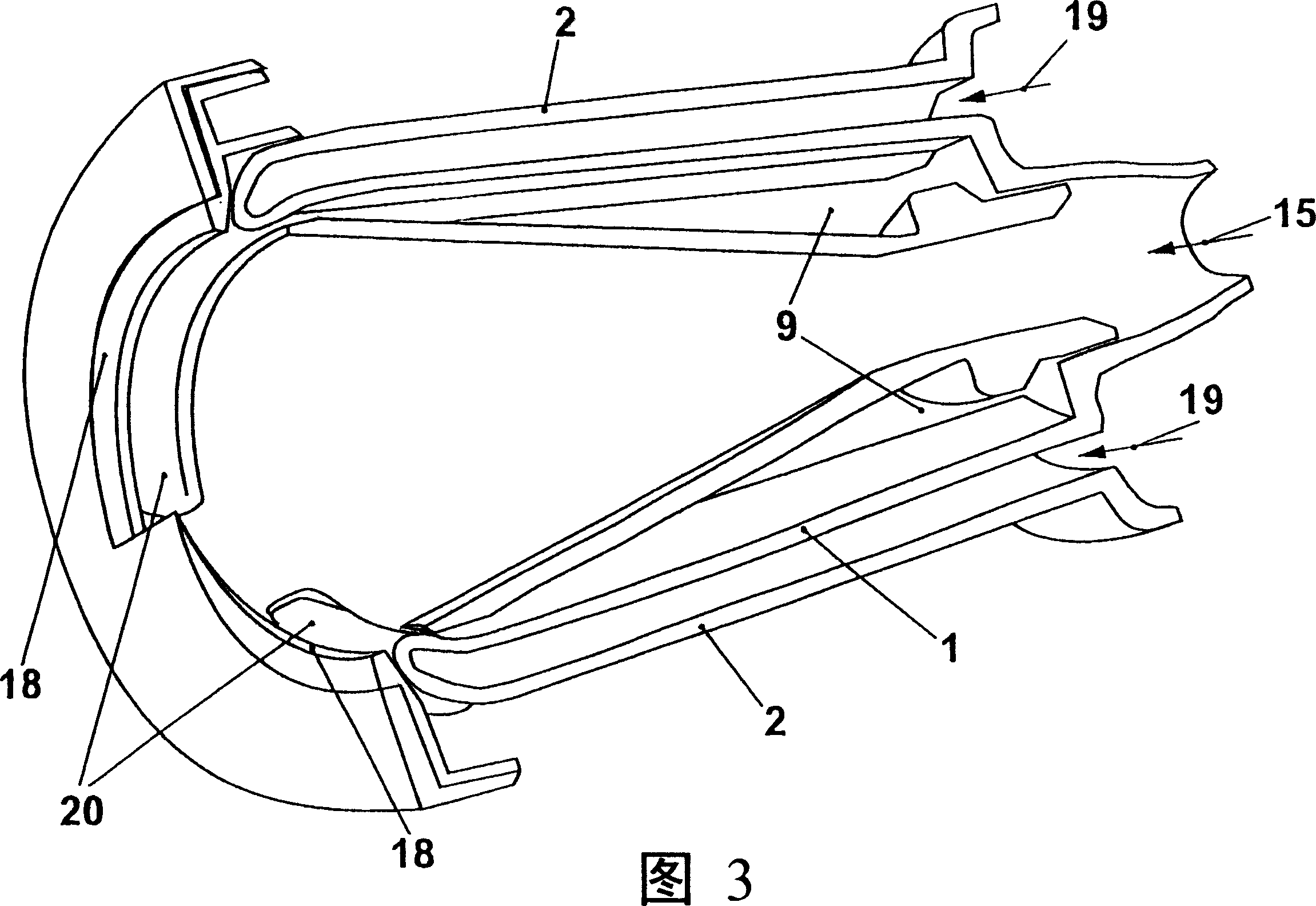

[0033] figure 1 A premix burner is shown very schematically, such as is known from EP 321 809 A1. The burner consists of a burner head 10 and a swirl generator 1 connected thereto, which forms a swirl space 11 . In such a burner, the conical swirl generator 1 consists of a plurality of burner shells, between which tangential inlet slots for the combustion air 9 are formed. The incoming combustion air 9 is indicated in the figure by a long arrow. Furthermore, a gas supply 24 can be provided along the tangential inlet grooves for feeding fuel, in particular natural gas 26, into the swirl space 11 via the tangential air inlet grooves. This fuel or natural gas is indicated in the figure by a short arrow. From the burner head 10 a burner nozzle 14 projects, which extends into the swirl space 11 and is provided at its end with a nozzle 16 for injecting a liquid fuel 13 , for example oil and / or water 12 . In particular, burner ignition will take place via the burner nozzle 14 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com