Plating machine and process for producing film carrier tapes for mounting electronic parts

A technology of electronic components and electroplating machines, applied in the direction of electrical components, electrolytic components, electric solid devices, etc., can solve problems such as coating failure, and achieve the effect of reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

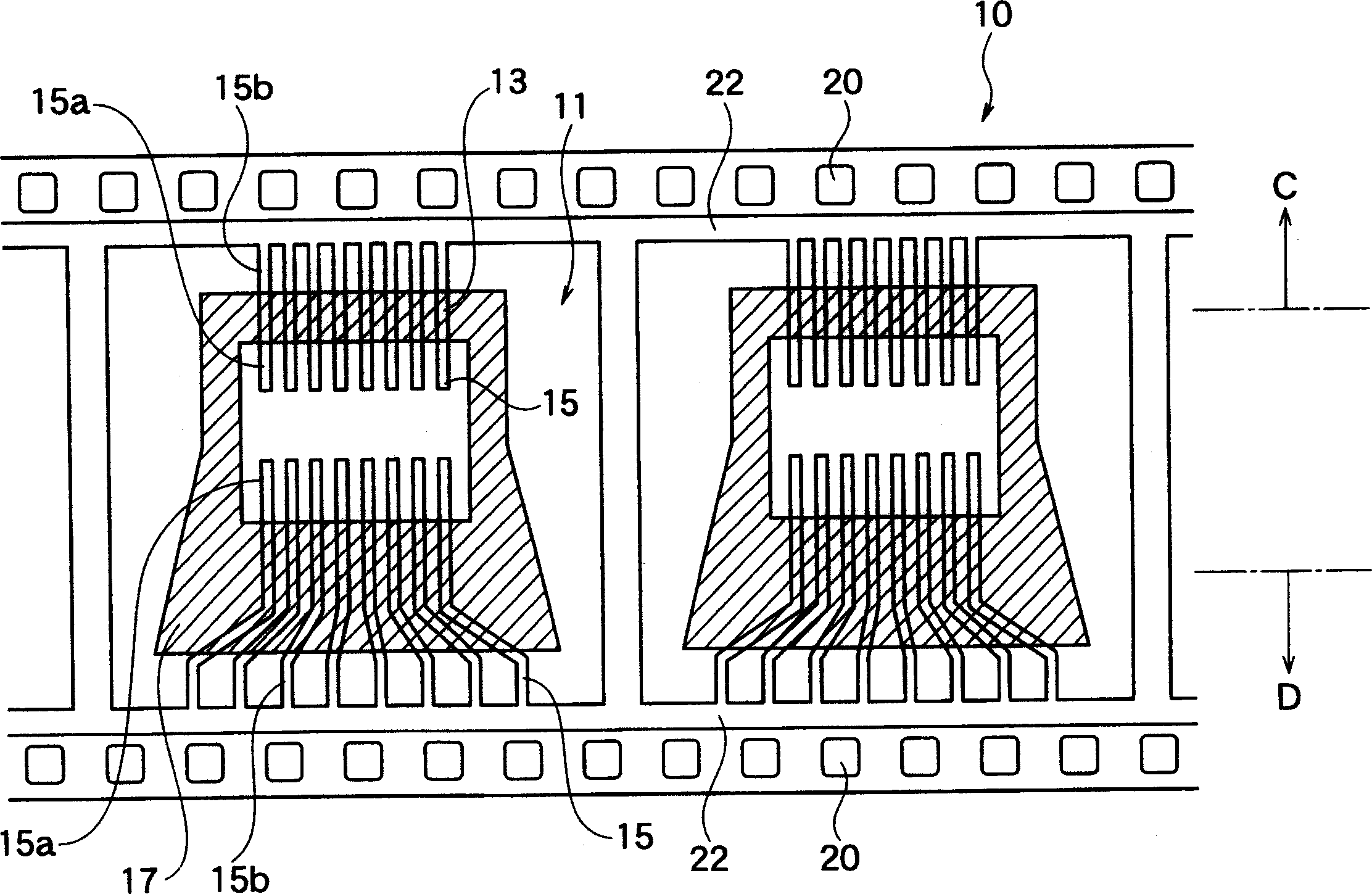

[0104] Polyimide long film (UPILEX) with average thickness 50 μm, width 48 mm and length 120 m -S, available from UBE Industries Co., Ltd.) is perforated to produce a plurality of perforations near both edges in the width direction.

[0105] Thereafter, an electrodeposited copper foil having an average thickness of 25 μm was soldered to the polyimide film. The electrodeposited copper foil is then coated with a photosensitive resin, which is exposed and developed to form a resin pattern.

[0106] Subsequently, the electrodeposited copper foil is etched using the above-formed pattern as a mask material. Thus, a wiring pattern of copper is produced. The mask material (exposed resin pattern) is removed by alkaline cleaning.

[0107] The wiring pattern is then coated with a solder resist coating liquid in all surfaces except the areas corresponding to the inner and outer leads. The coating is then dried to produce a solder resist layer.

[0108] The strip with solder mask pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com