Substrate processing apparatus and method for adjusting a substrate transfer position

A technology of substrate processing device and handover position, which is applied in the direction of photolithography process exposure device, transportation and packaging, lighting and heating equipment, etc., can solve the problems of time-consuming, uneconomical, discrete sensitivity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

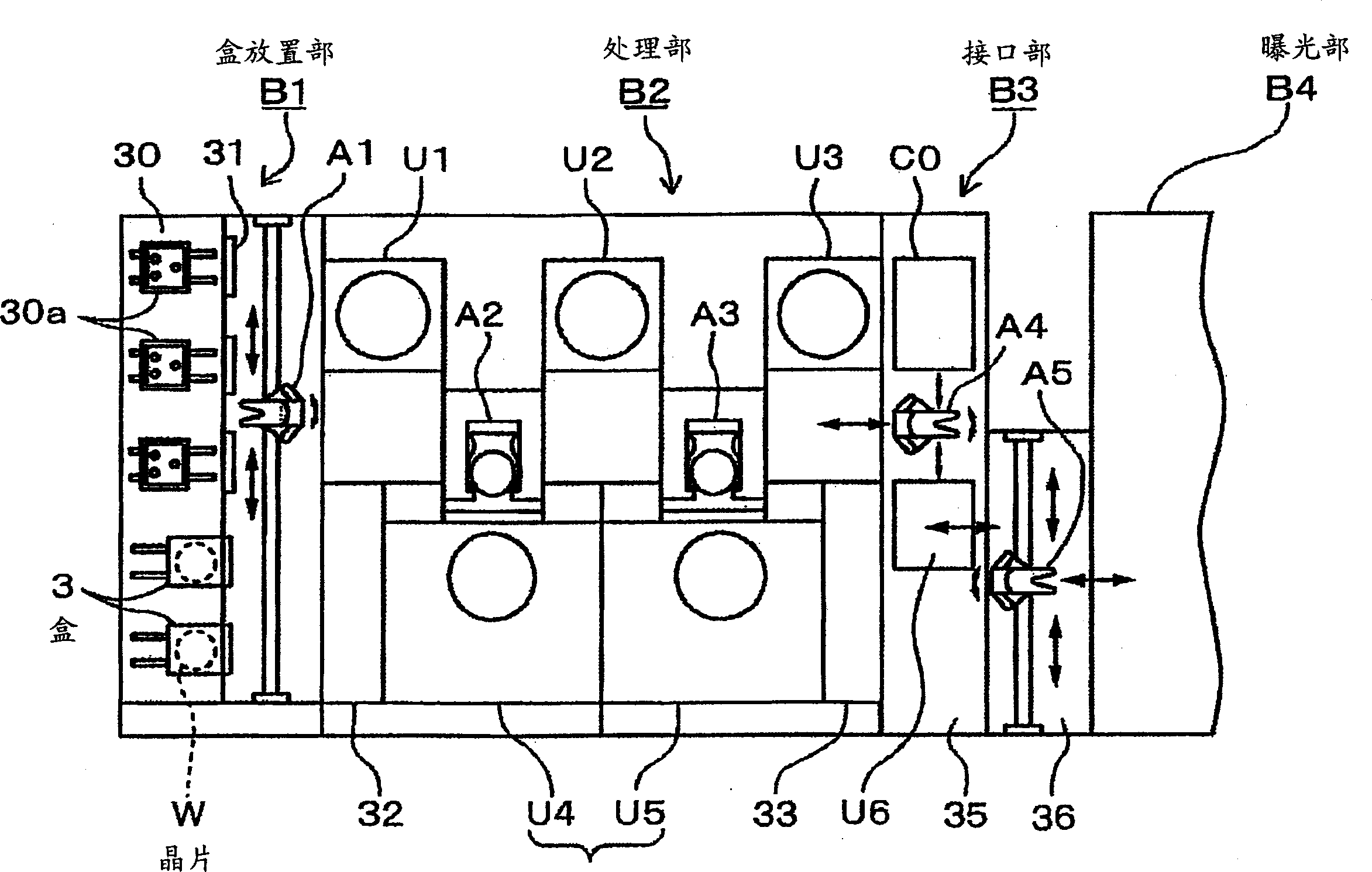

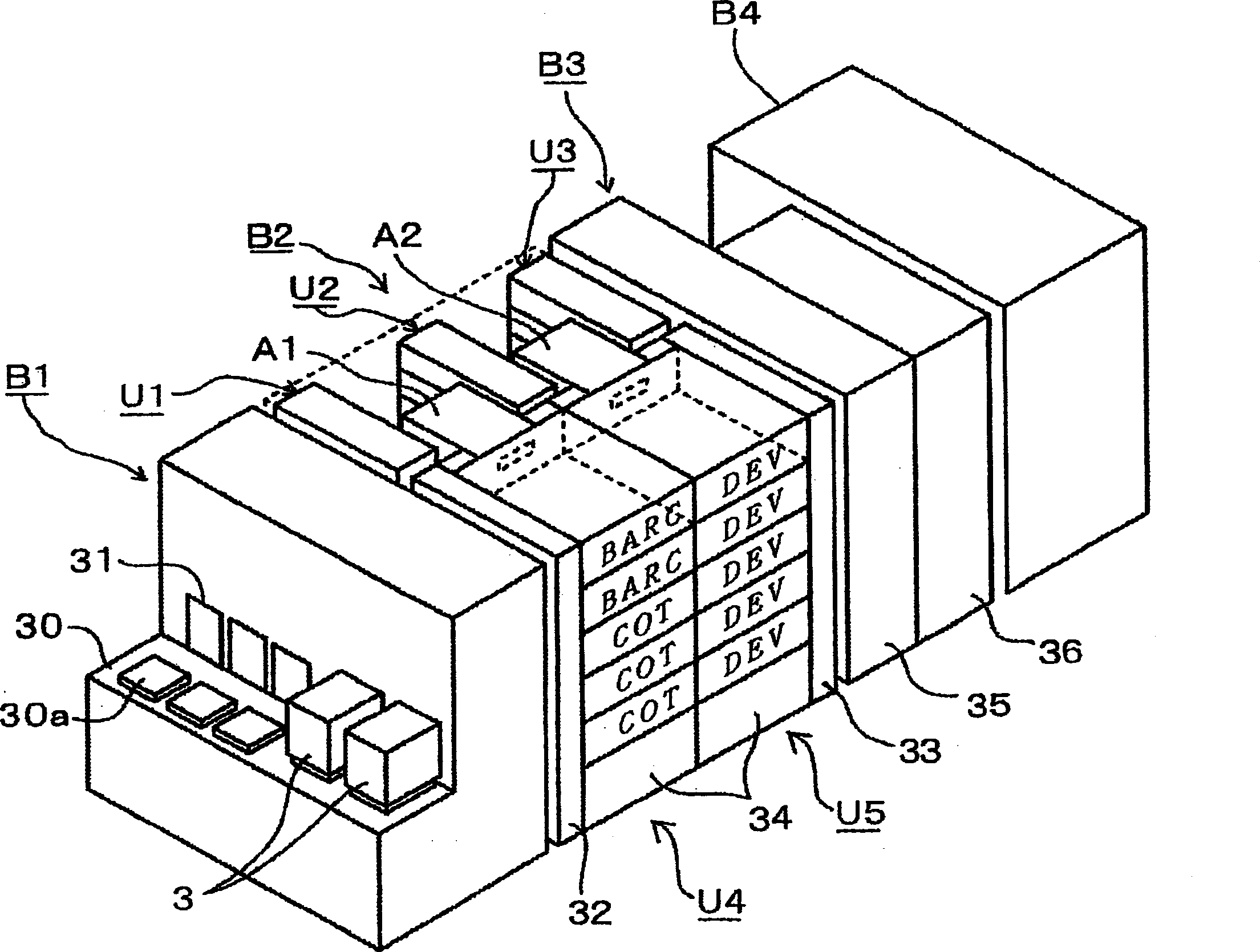

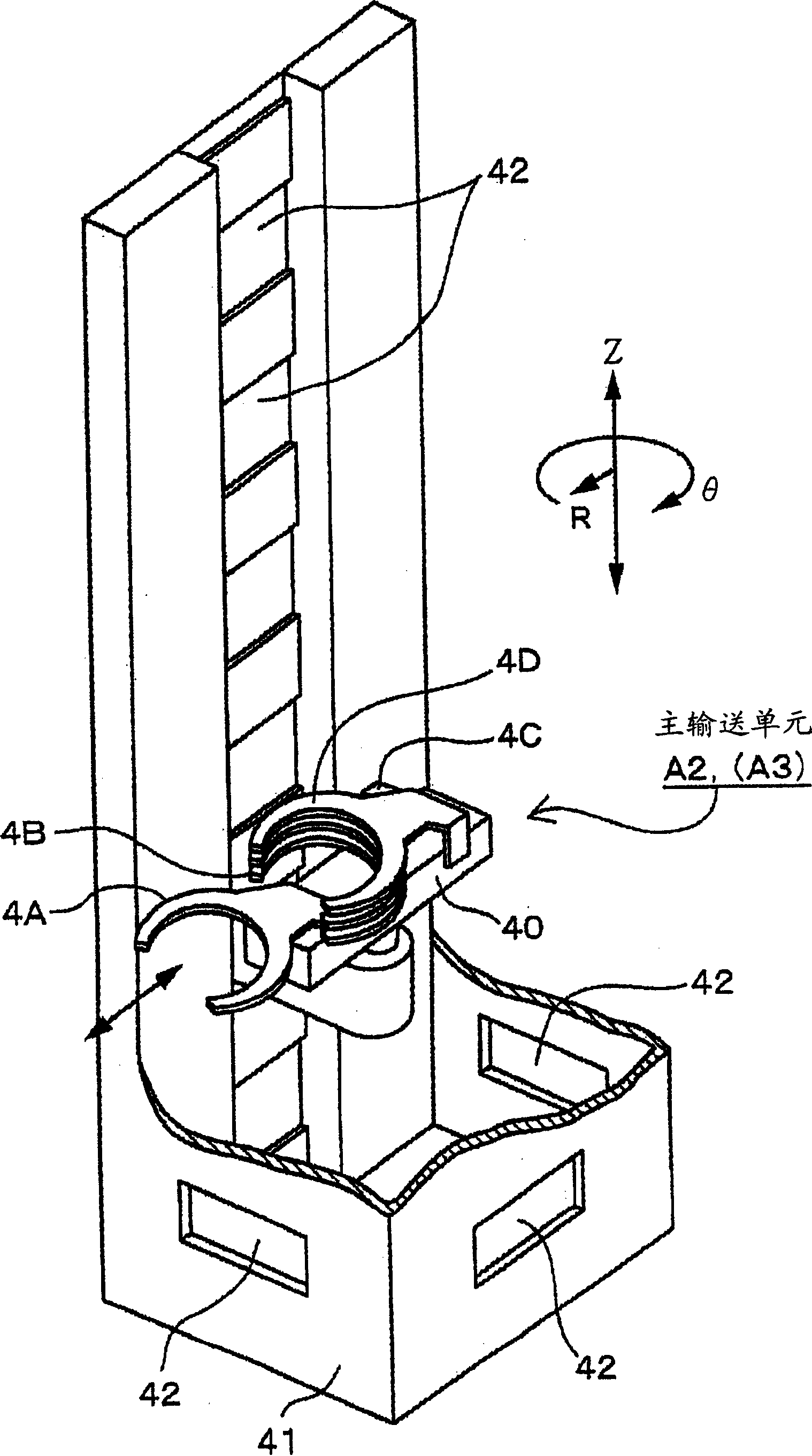

[0074] First refer to figure 1 and figure 2 A coating and developing apparatus according to an embodiment of the substrate processing apparatus of the present invention will be described. B1 in the figure is a cassette loading section for loading and unloading cassettes 3 that house 13 wafers W as substrates in a hermetically sealed manner. As seen from the table 30, there is an opening and closing unit 31 provided on the front wall surface; In addition, the rear side of the cassette loading part B1 is connected to the processing part B2, and the processing part B2 is provided with: rack units U1, U2, U3 in which the units of the heating and cooling system are multi-staged; Liquid processing units U4, U5 that perform predetermined liquid processing; and main transfer units A2, A3 that transfer wafers W to and from each unit. That is, the main transfer units A2 and A3 are configured to be able to access adjacent units, and the wafer W can freely move from the rack unit U1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com