Air lift plant cell culture biological reactor with screen mesh guiding drum

A bioreactor and plant cell technology, which is applied in the field of airlift plant cell culture bioreactor, can solve the problems of affecting the generation of metabolites affecting cell growth, causing great damage to plant cells, and the inoculum volume cannot be too large, so as to solve the problem of spontaneous rupture. Dissolution, easy operation, and the effect of reducing sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

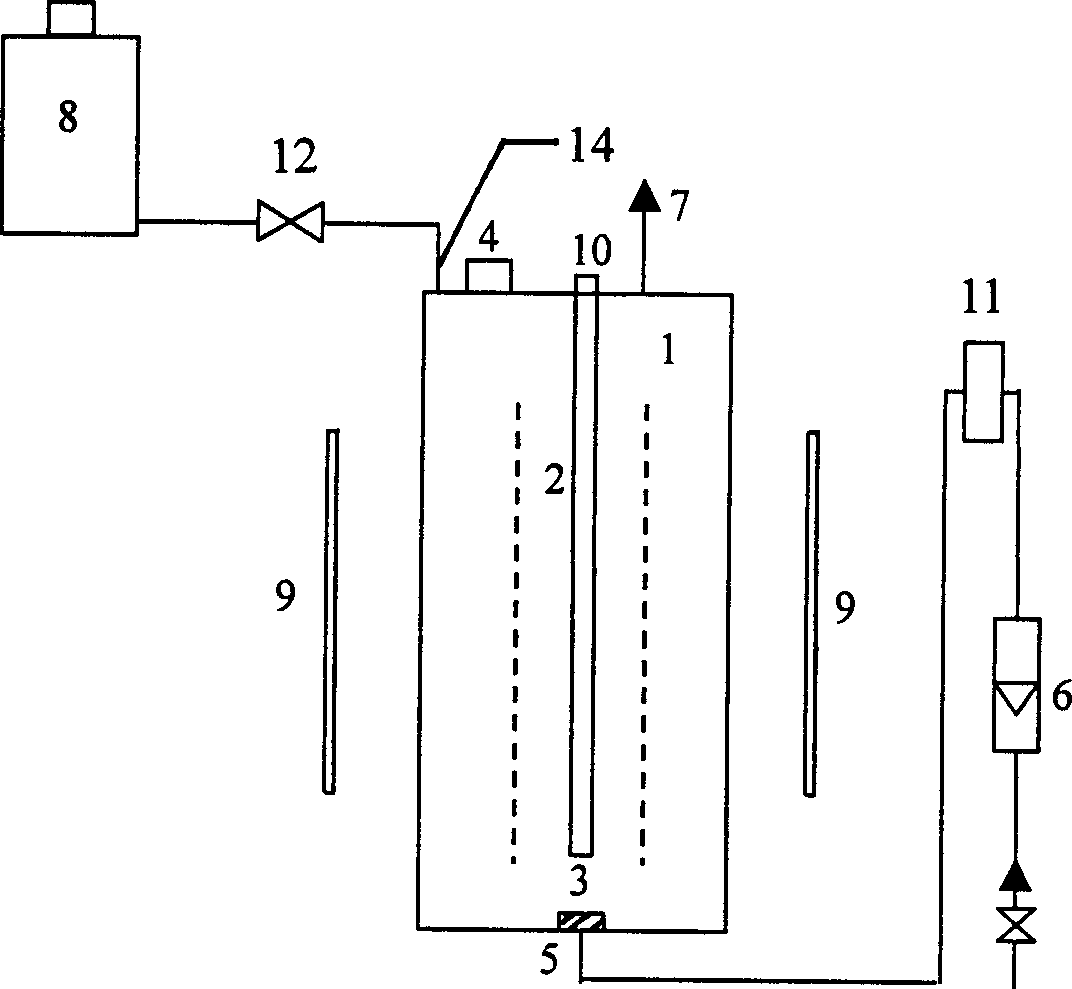

[0024] Prepare 1 set of 2L screen-type draft tube air-lift plant cell culture bioreactor provided by the present invention, such as figure 1 As shown, a reactor body 1 made of φ120mm×300mm heat-resistant glass, the built-in light source 10 is fixed on the top cover of the reactor body along the axis of the reactor body 1, and a screen made of stainless steel mesh The type guide tube 2 is axially screwed and fixed on the bracket at the bottom of the reactor, and is located in the center of the reactor main body 1, and the circular gas distributor 3 located directly below the screen type guide tube 2 is fixed on the reactor main body 1 On the base plate, the circular gas distributor 3 communicates with the air inlet 5 on the base plate, and the air inlet 5 links to each other with an external air compressor, and an air filter 11 is installed on the connecting pipe, and a gas flowmeter 6 (with to adjust the size of the air flow), the reactor main body 1 is evenly equipped with an...

Embodiment 2

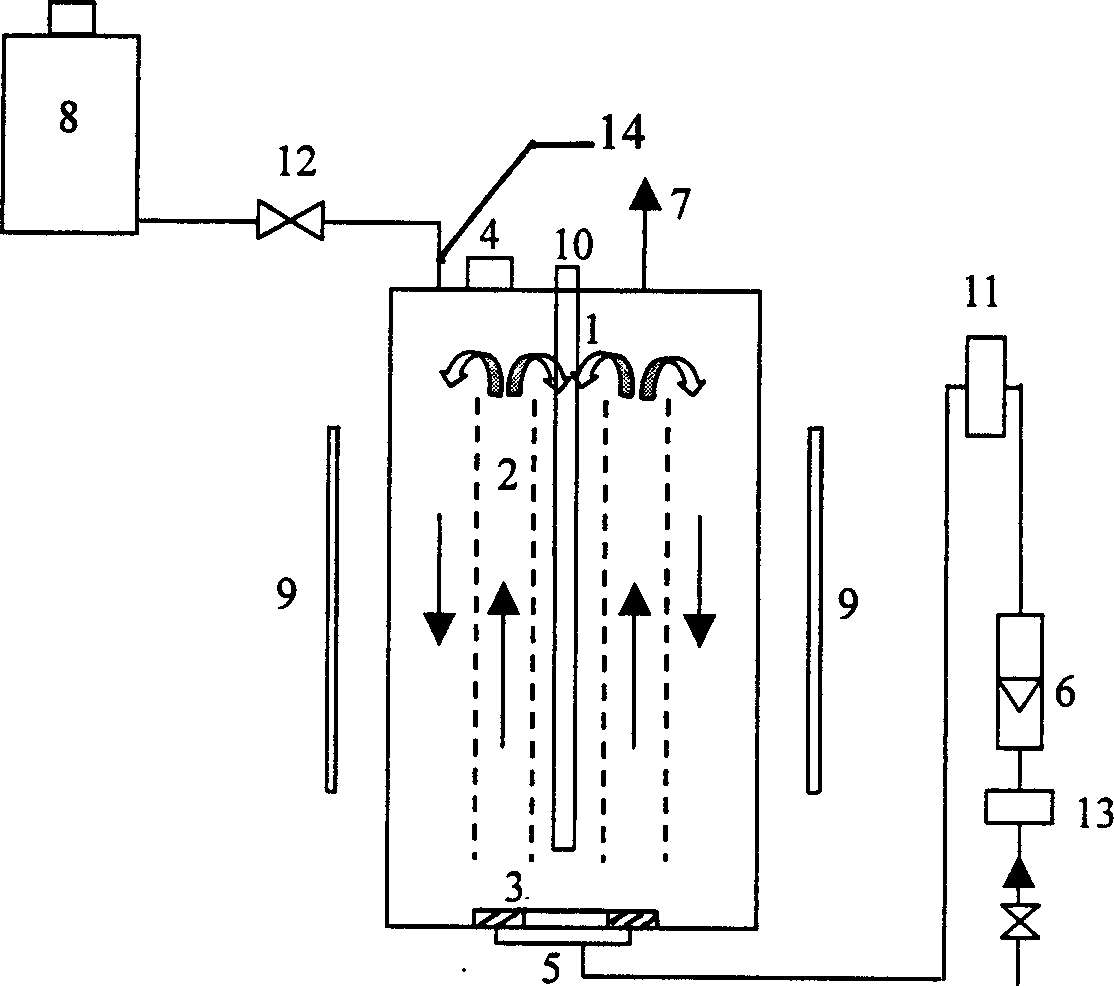

[0026] Prepare 1 set of 2L screen-type draft tube air-lift plant cell culture bioreactor provided by the present invention, such as figure 2 As shown, a reactor body 1 made of φ120mm×300mm heat-resistant glass, the built-in light source 10 is fixed on the top cover of the reactor body along the axis of the reactor body 1, and two diameters made of stainless steel mesh are respectively The 40mm and 80mm screen-type draft tubes 2 are coaxially set and fixed in the reactor main body 1, and an annular gas distributor 3 is arranged directly below the annular area of the screen-type draft tube 2, and the annular gas distributor 3 is installed on the bottom plate of the reactor main body 1, and communicates with the air inlet 5, which is connected with an external air compressor, and an air filter 11, a gas temperature control device 13 and a gas flow meter 6 are installed on the connecting pipe, An external fluorescent tube 9 is evenly arranged around the reactor main body 1, and...

Embodiment 3

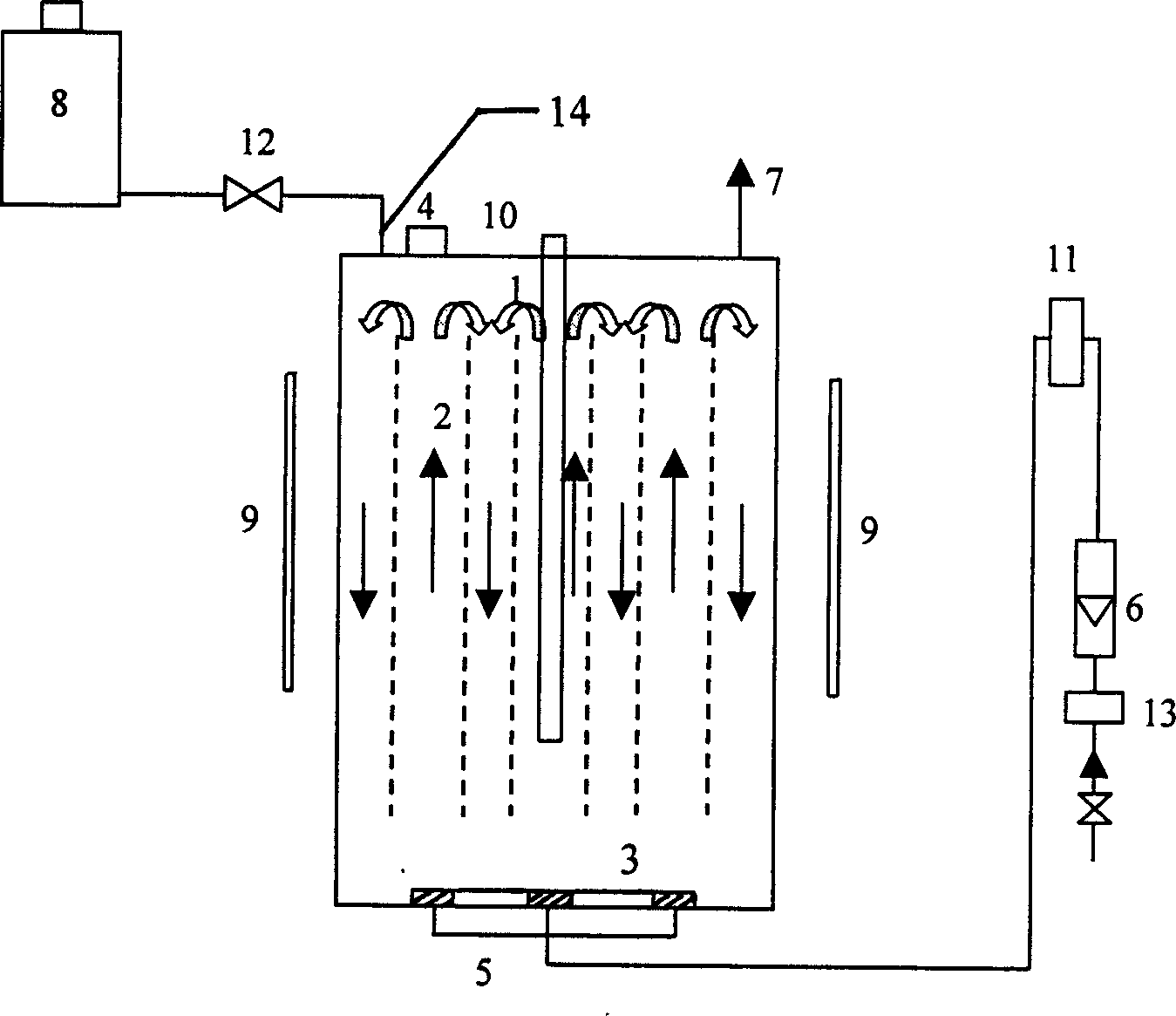

[0029] Prepare a 40L screen-type draft tube air-lift plant cell culture bioreactor, such as image 3 As shown, a reactor main body 1 made of heat-resistant glass of φ230mm×1400mm, three screen-type guide tubes 2 with diameters of 60mm, 120mm and 180mm made of stainless steel mesh are fixed on the reactor. In the reactor main body 1, the built-in light source 10 is fixed on the top cover of the reactor main body along the axis of the reactor main body 1. The built-in light source 10 is made by inserting a fluorescent tube into a φ40mm heat-resistant glass built-in light tube.

[0030] There is a circular gas distributor in the circular area directly below the screen-type draft tube located in the center, and there is an annular gas distributor 3 directly below the annular area between the two screen-type draft tubes on the periphery. The two gas distributors 3 are all installed on the bottom plate of the reactor main body 1, and communicate with the air inlet 5, which is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com