High-density chip scale package and method of manufacturing the same

A chip-size packaging and high-density technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

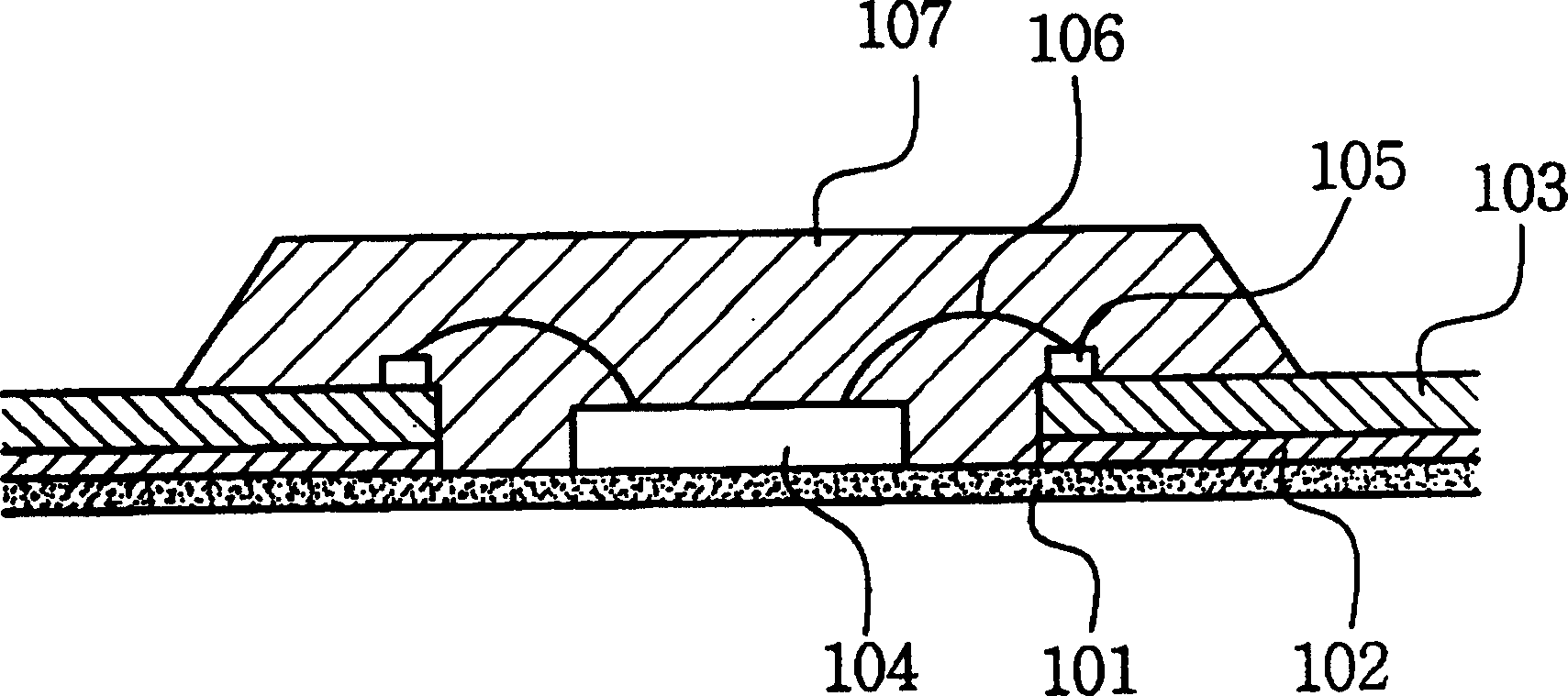

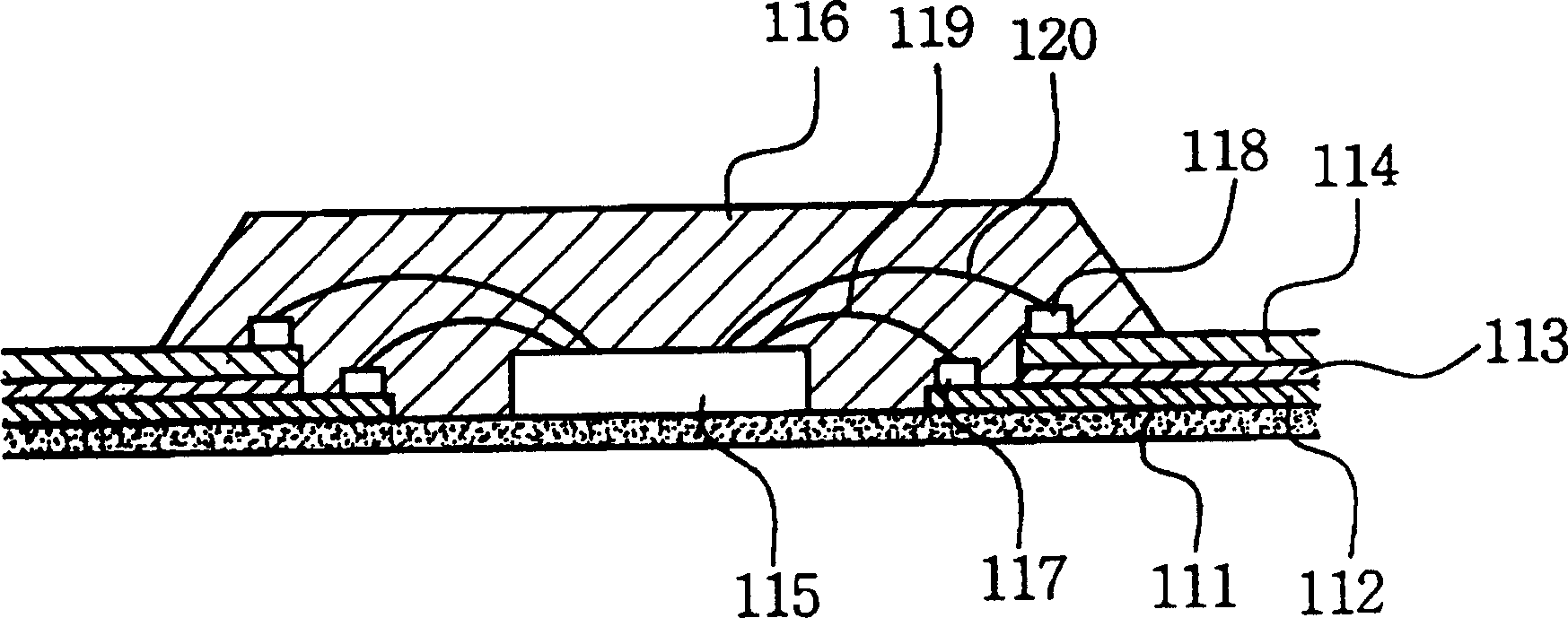

[0051] Figures 3a to 3i A cross-sectional view showing a process of manufacturing a high-density chip-scale package using a heat radiation structure according to a preferred embodiment of the present invention, wherein a die is mounted on the package by wire bonding techniques.

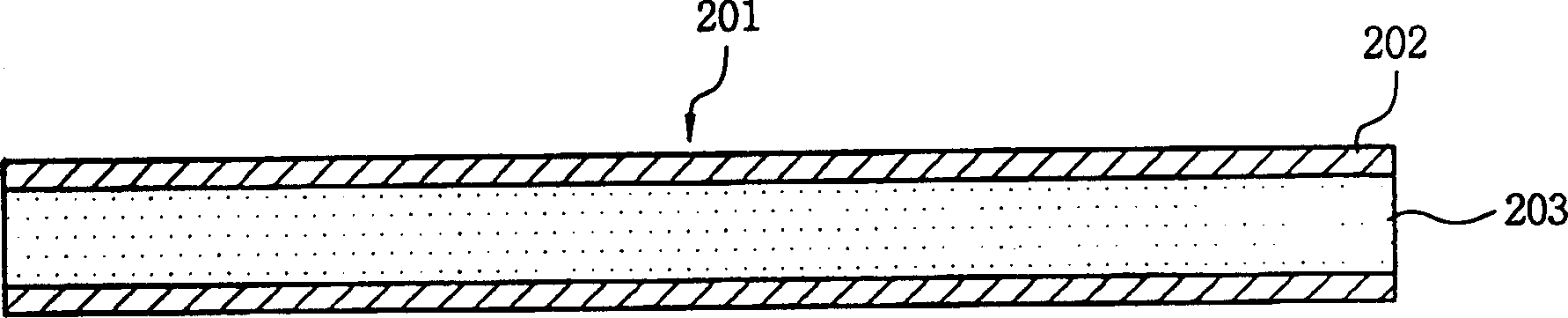

[0052] Figure 3a is a cross-sectional view of a copper-clad thin laminate 301, which is a substrate used in the high-density chip-scale package of the present invention. Such as Figure 3a As shown, the insulating layer 303 is covered with copper foil 302 . There are various copper clad thin laminates. However, a glass / epoxy resin copper-clad thin laminate composed of a reinforcing material obtained by infiltrating an epoxy resin (a mixture of a resin and a hardener) into glass fibers and copper foil is mainly used. In particular, copper-clad thin laminates designated FR-4 are most commonly used. An FR-4 copper-clad thin laminate is used as the copper-clad thin laminate in the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com