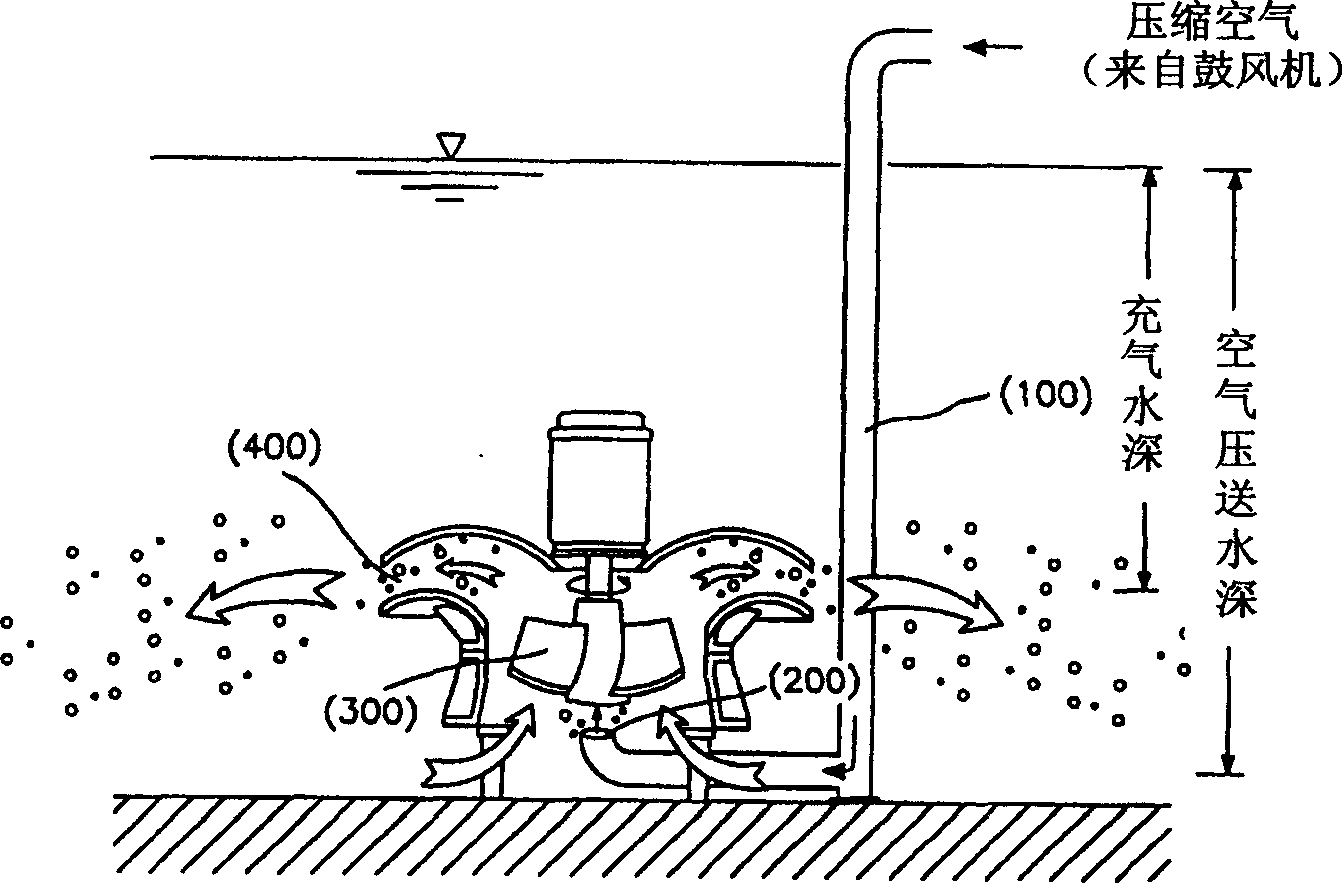

Submerged aerator with multi-step mixing and separation function

An inflatable device and dispersion technology, which is applied to mixers with rotating agitating devices, mixers, mixing methods, etc., can solve the problems of low oxygen mobility, achieve high oxygen mobility, easy lifting and installation, and inflatable power Excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

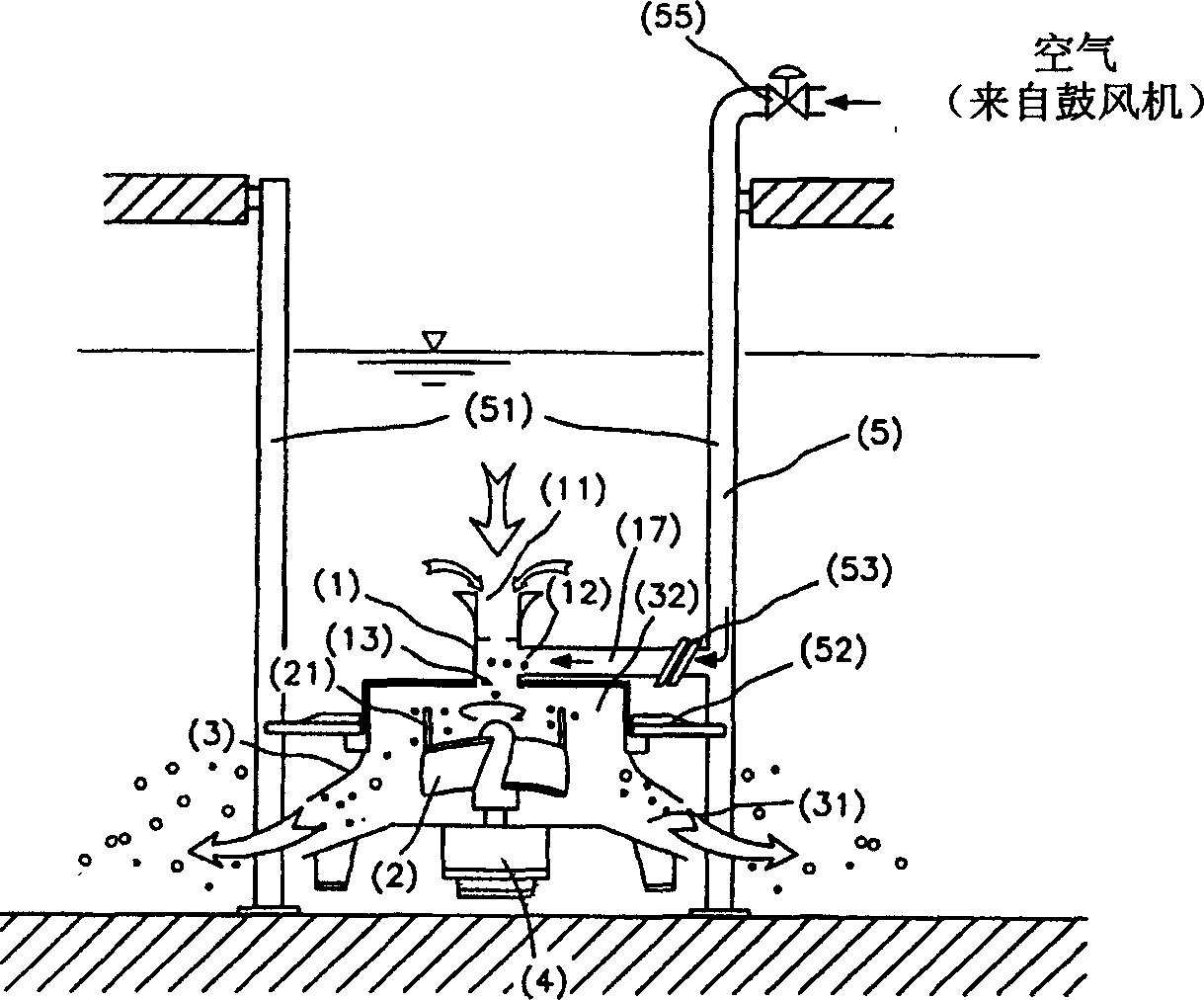

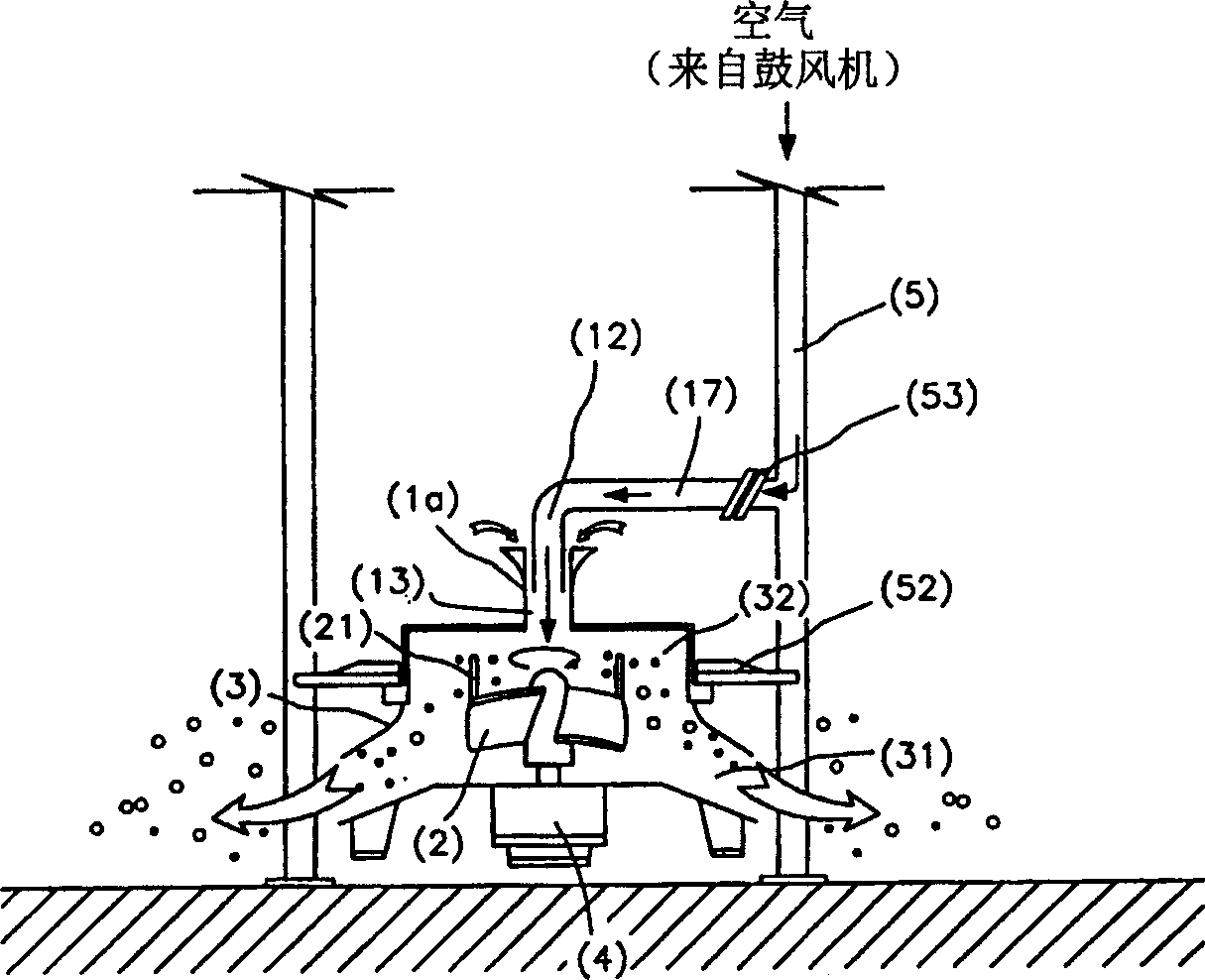

[0024] The lower part describes the embodiments of the present invention in detail in conjunction with the accompanying drawings.

[0025] figure 2 It is a schematic diagram of the first embodiment of the underwater aeration device of the present invention.

[0026] The underwater aeration device according to this embodiment has the following structure: there are rotating blades 2 inside the casing 3 . A standard injector 1 is arranged on the upper part of the above-mentioned casing center, and the injector 1 has a nozzle inside. The water flow inlet of the above-mentioned injector is constituted by a chute pipe. The air suction port of the above-mentioned injector is connected with the air delivery pipe 5 for delivering the air from the blower. The outflow port 13 of the injector is connected to the inside of the casing in a communication manner, so that the gas-liquid mixed fluid formed by mixing the air flowing out of the injector and the reaction liquid can flow into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com