Oil-jetting pump oil-quantity automatic measuring testing table

An automatic measurement and test bench technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., can solve problems such as low work efficiency and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

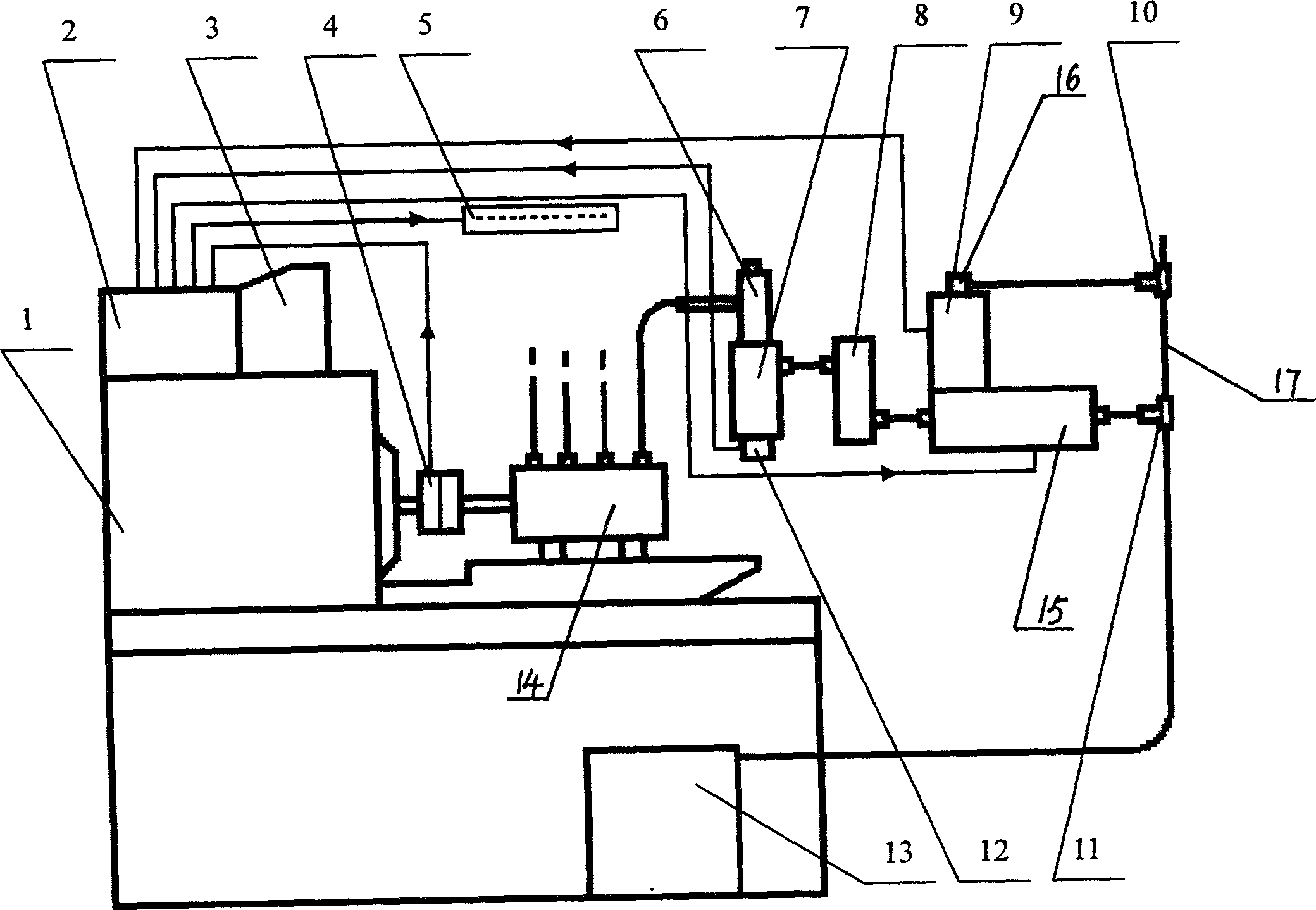

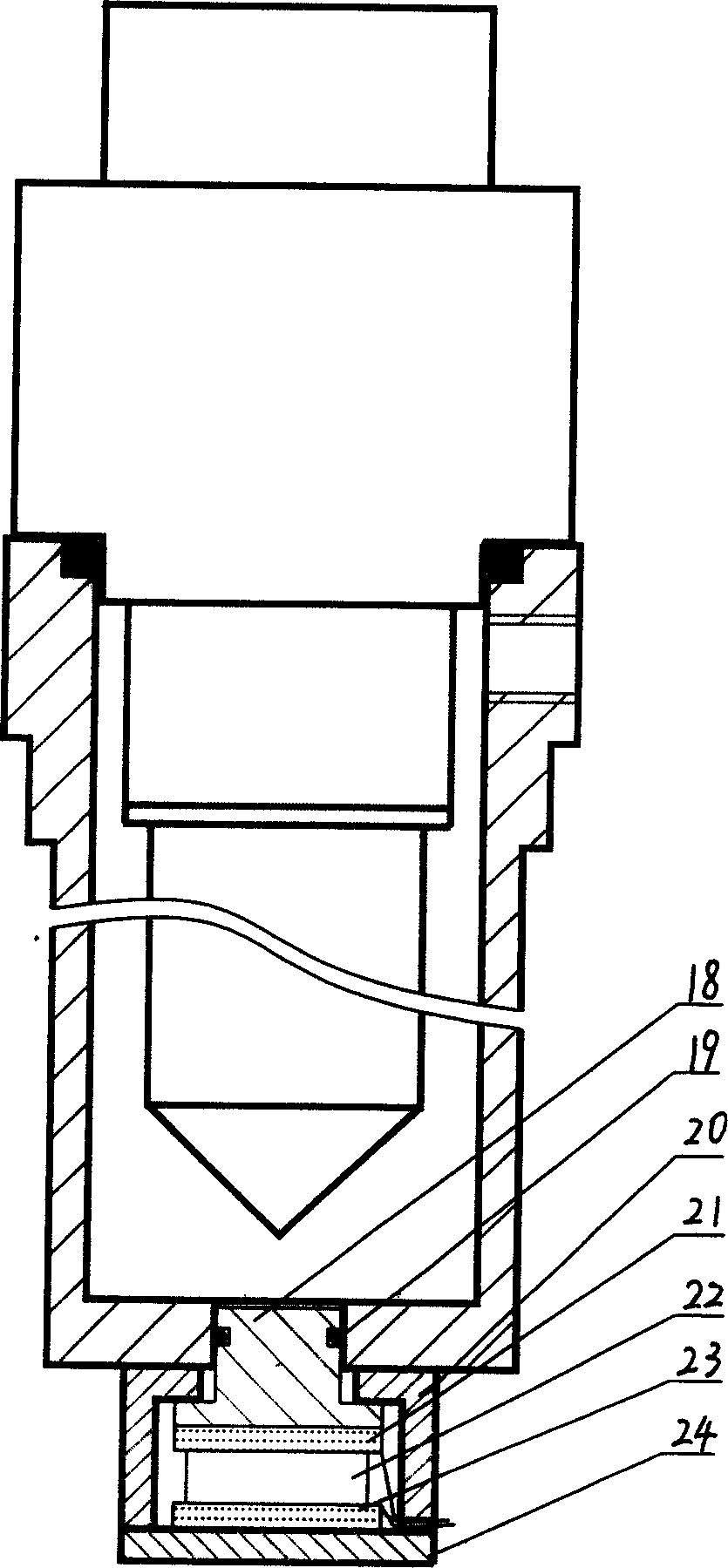

[0012] Such as figure 1 , figure 2 As shown, the test bench of the present invention includes a fuel injector 6, an oil collector 7, a defoaming regulator 8, an oil production and discharge solenoid valve 15 and a flow sensor 9, and between the inlet of the fuel injector 6 and the outlet of the oil pump 14 The oil collector 7 is installed on the outlet of the injector 6. The outlet of the oil collector 7 is connected to the defoaming regulator 8 through a conduit. The inlet of valve 15 links to each other, and flow sensor 9 is installed on the oil production and discharge solenoid valve 15, and the oil outlet 16 of flow sensor 9 and the oil outlet of production and discharge solenoid valve 15 link to each other with oil tank 13 by oil return pipe 17 respectively. The flow sensor in this embodiment is a volumetric sensor, and the volumetric sensor is a circular tube sensor. An upper and a lower pair of photoelectric sensors are respectively installed on the opposite sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com