Extruding extractor and continuous dynamic Chinese medicine countercurrent extracting system thereof

An extractor and countercurrent technology is applied in the field of equipment for extruding and extracting effective components in plants, which can solve the problems of low production capacity and production efficiency, low extraction rate of effective components, and large equipment footprint, and achieves improved performance. The degree of automation, the reduction of solvent consumption, the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

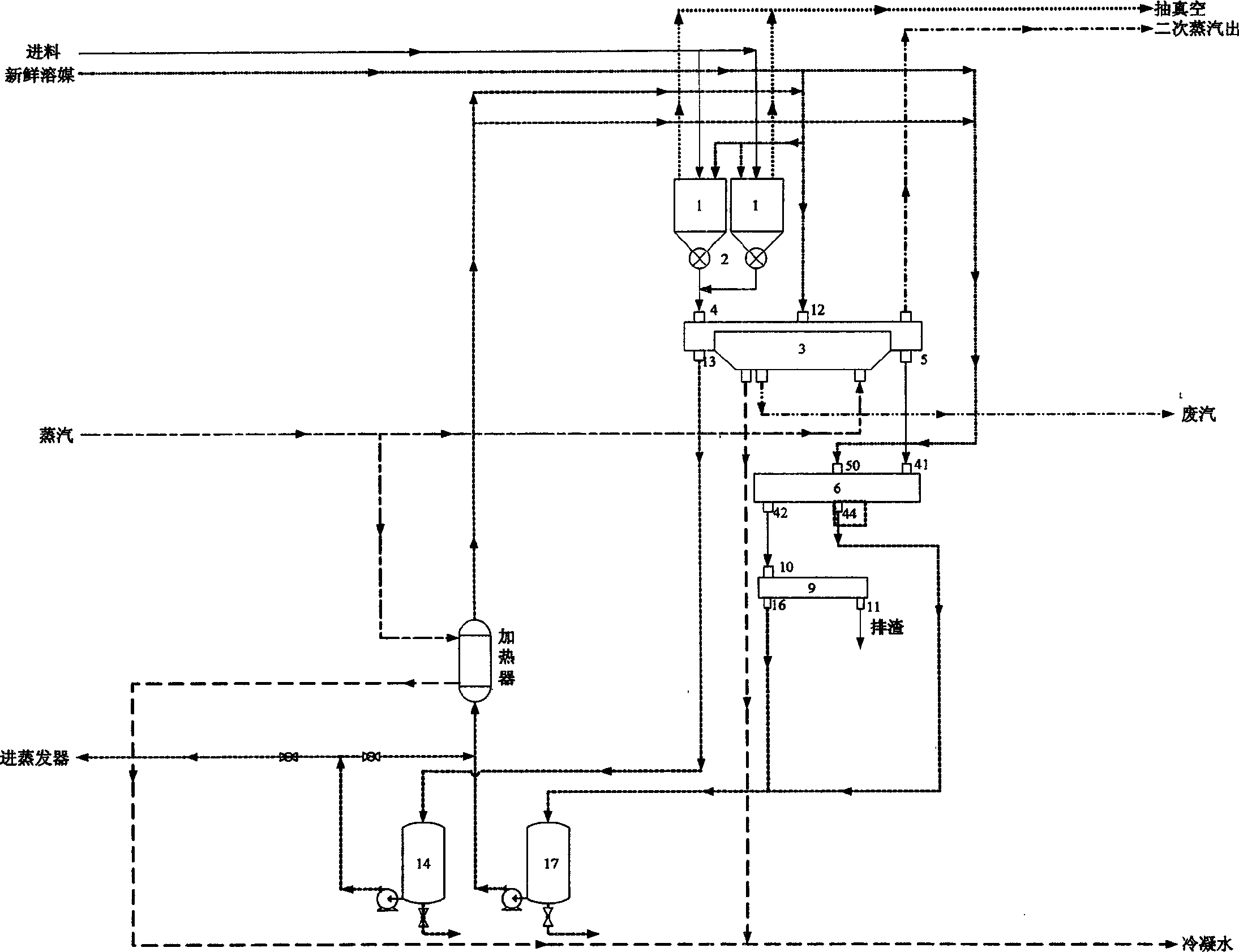

[0023] The invention will be further described below in conjunction with the accompanying drawings.

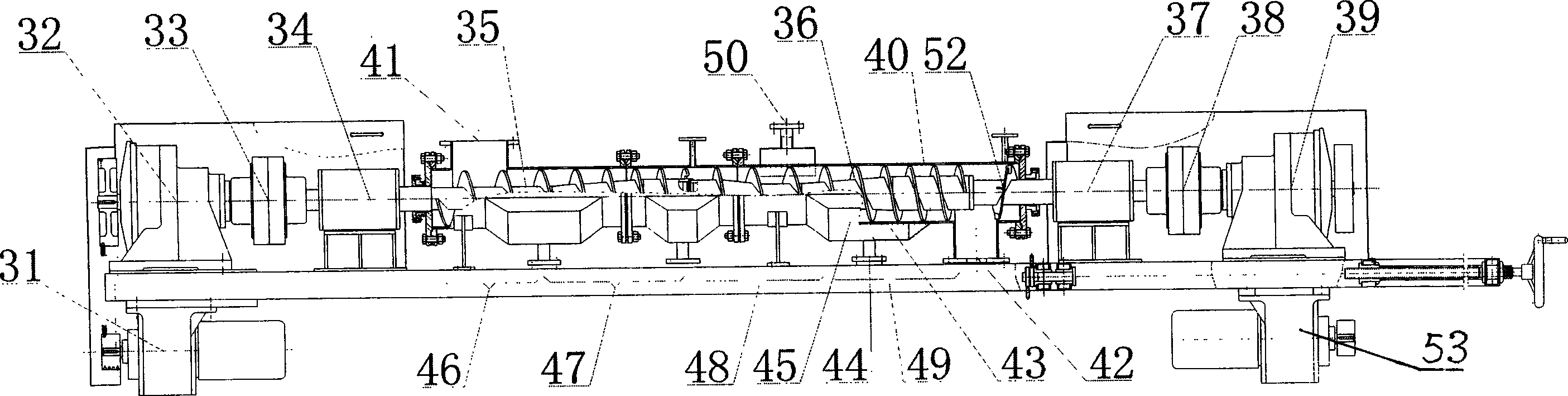

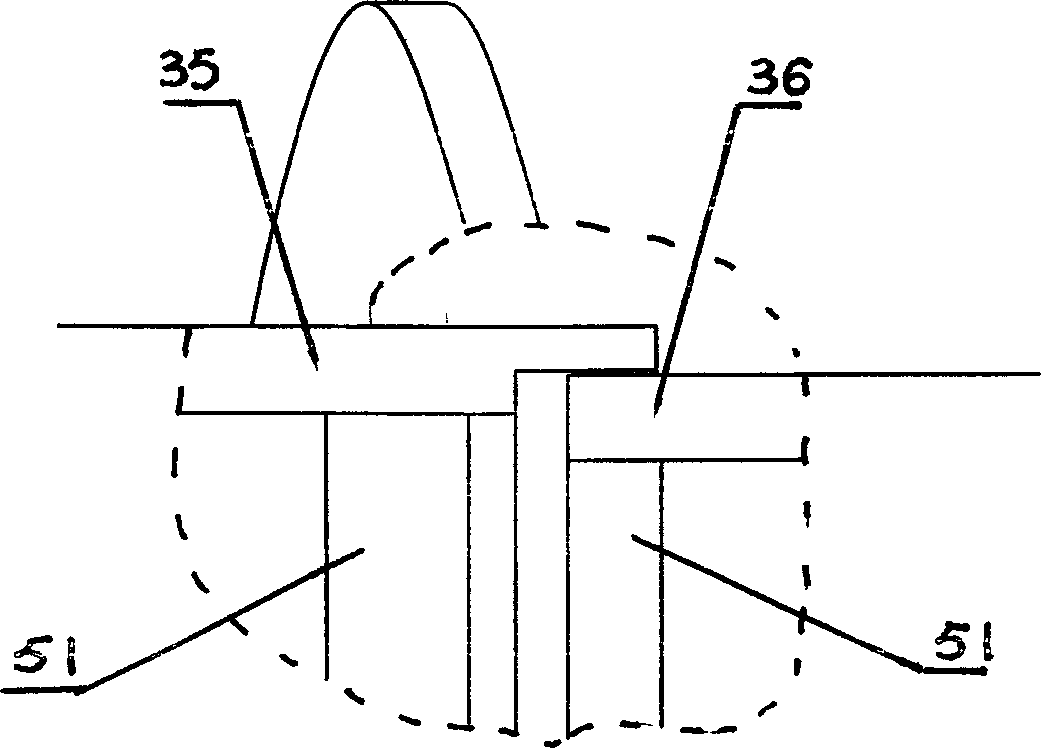

[0024] A squeeze extractor, the first speed regulating motor 31 is sequentially connected with the first reduction box 32, the first coupling 33, the first bearing seat 34, and the first screw rod 35, and the first screw rod 35 and the second screw rod 36 are movable connection, the second screw rod 36 is connected with the second bearing seat 37, the second coupling 38, the second reduction box 39 and the second speed regulating motor 53 in turn, and the outside of the first screw rod 35 and the second screw rod 36 is provided with a barrel 40 One end upper part of machine barrel 40 is provided with extruding extractor inlet 41, the bottom of the other end of machine barrel 40 is provided with extruding extractor outlet 42, and the bottom of machine barrel 40 is provided with filter plate 43, filter The bottom of the plate 43 is provided with a liquid collection tank 45 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com