Combined measuring device for fabric and yarn mechanics index and use

A measuring device and yarn technology, which is applied in the direction of measuring devices, textile testing, scientific instruments, etc., can solve the problems of not effectively extracting mechanical performance indicators, and achieve the effect of compact structure, simple mechanism and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

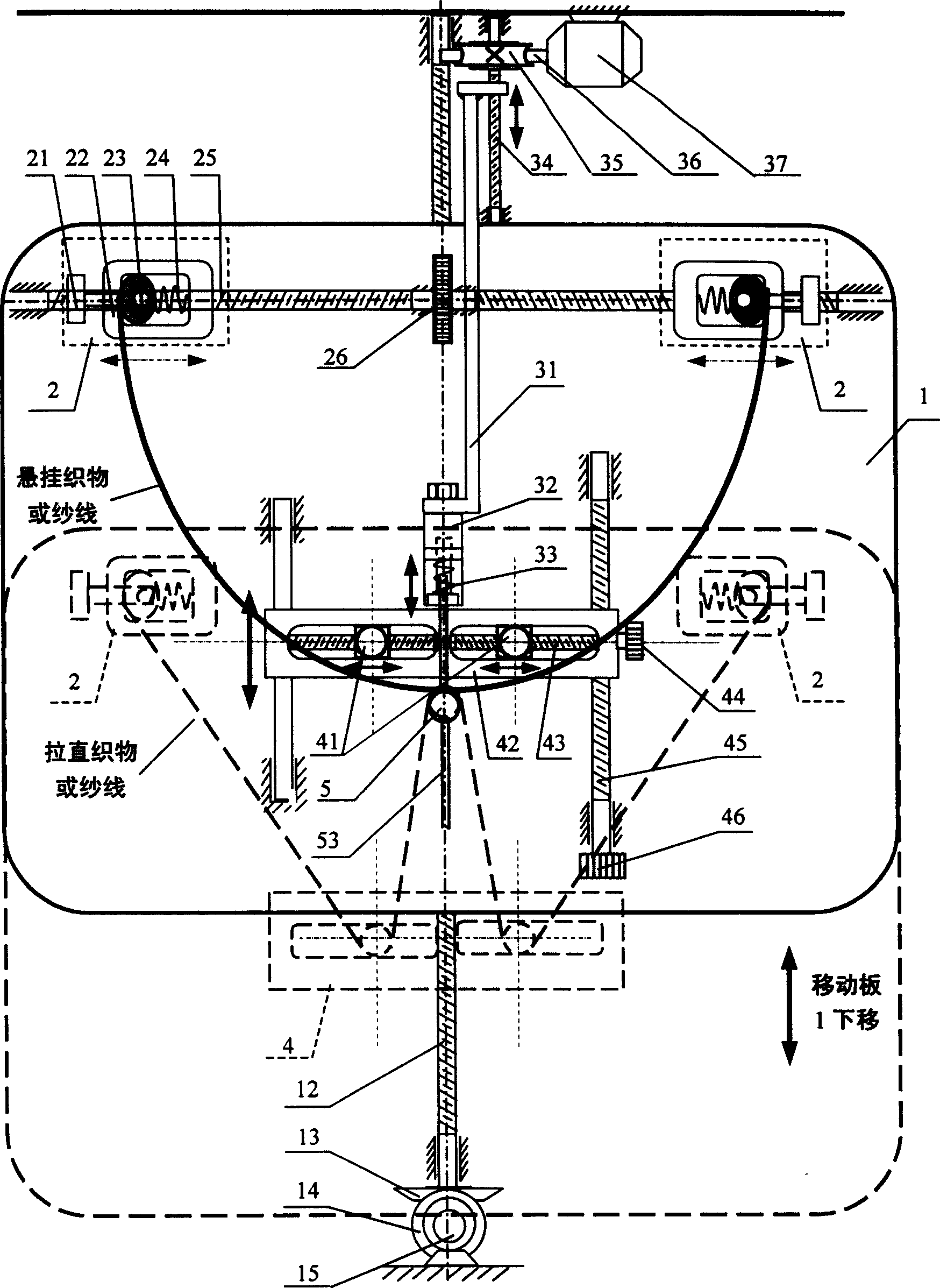

[0051] Example 1, the composite force-displacement characteristic curve is obtained.

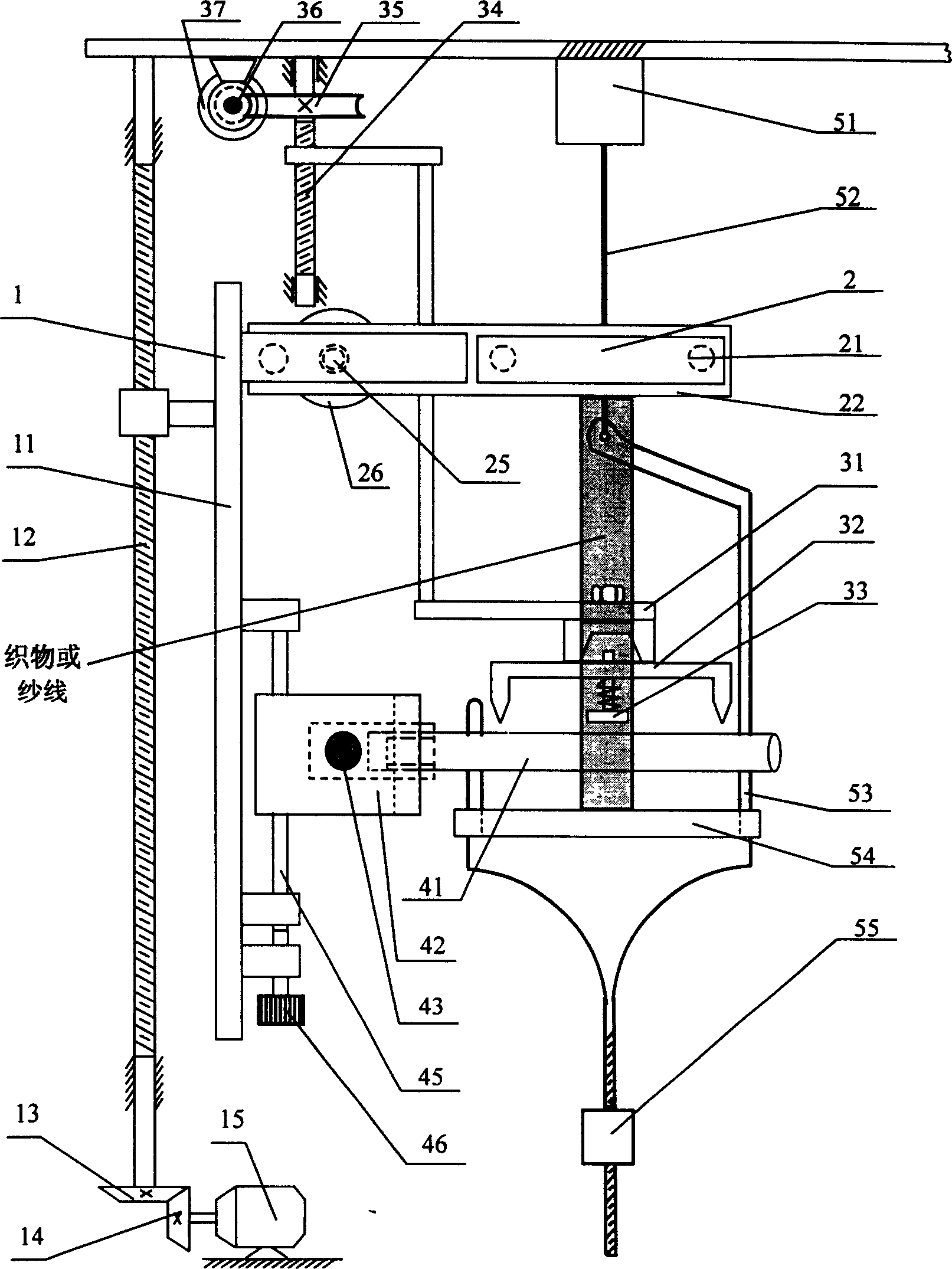

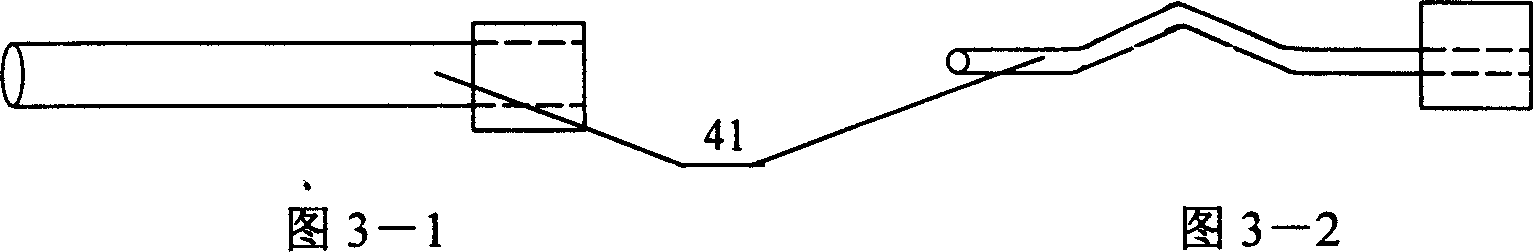

[0052] The driving screw 12 of the moving plate 1 and the driving stepper motor 15, the two-stage contact block thickness measuring mechanism 3 and the driving micro-motor 37, and the tension sensor 51 of the single fixed-point supporting needle 5 are all fixed with the frame. The moving plate 1 is driven by the screw to move in the vertical position; the two-stage contact block thickness measuring mechanism 3 drives the worm gear 35 and the worm 36 to rotate the rotating screw 34 by driving the micro motor 37, and pushes the holding plate 31, the contact block bracket 32 and the sliding spring to slide Block 33 moves down to finish the thickness measurement of yarn or fabric sample; converted into a digital signal.

[0053] Rotate the screw rod 25 symmetrically according to the requirements of the measurement, and move the left and right upper fixed clamps 2 symmetrically to the desired ...

Embodiment 2

[0057] Embodiment 2, measurement result.

[0058] The composite force-displacement characteristic curve was obtained by measuring the average value of 10 fabric samples by this action, and the characteristic index of the mechanical properties of the fabric was extracted from it. The results are shown in Table 1.

[0059] Table 1 Combined measurement results of two groups of worsted wool fabrics

[0060] Weight Bending slope Maximum bending force Bending stiffness Bending work Friction Tensile modulus

[0061] serial number

[0062] (g) (cN / cm) (cN) (cN cm 2 ) (cN cm) (cN) (cN / cm)

[0063] 1# 0.57 0.19 3.91 0.149 66.68 1.82 0.17

[0064] 2# 0.58 0.23 5.51 0.254 102.4 2.55 0.18

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com