Thermoplastic precise forming nitrogen protection oxidation preventing system

A nitrogen protection and oxidation system technology, applied in metal processing equipment and other directions, can solve problems such as affecting the dimensional accuracy of formed parts, surface quality mold service life, labor-intensive coating and cleaning, affecting the surface quality of workpieces, etc. Best results, improved material utilization, increased geometric accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the embodiment shown in the accompanying drawings, further illustrate the specific content of the present invention and working process thereof:

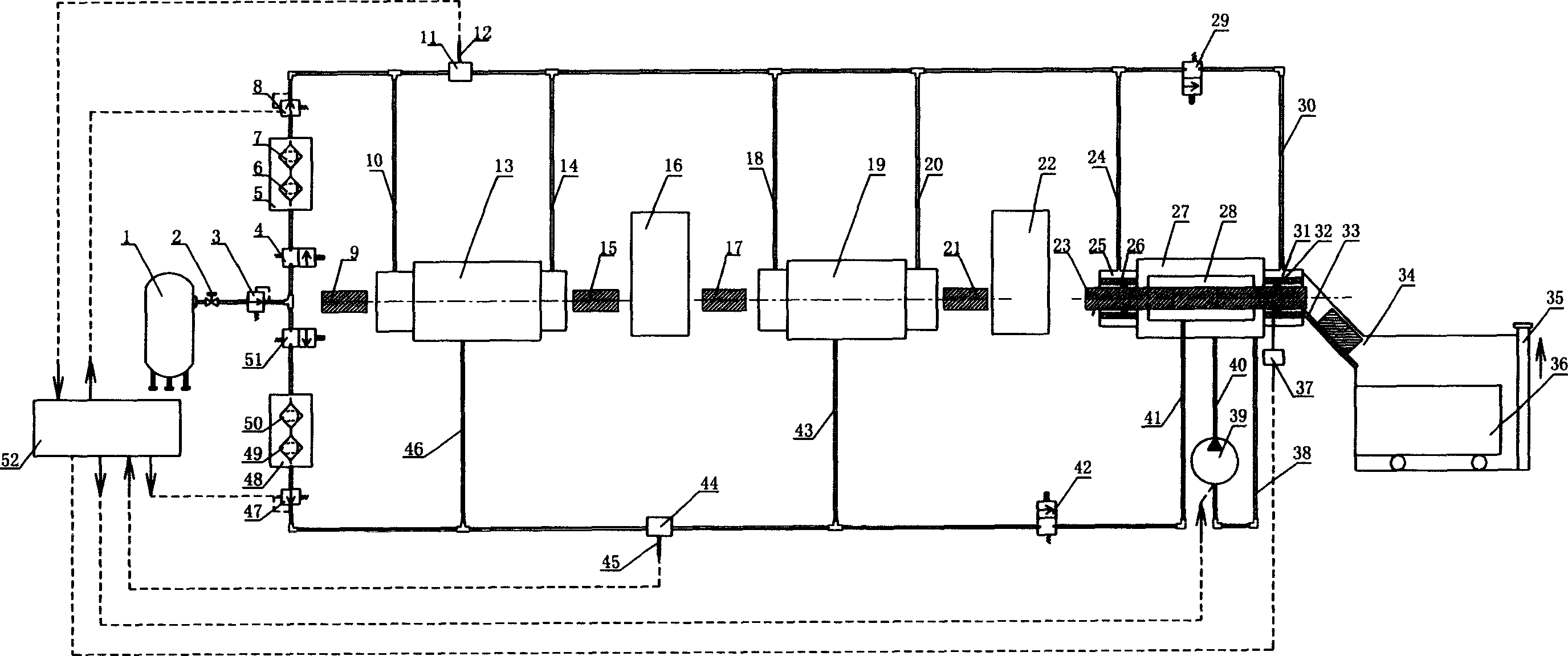

[0020] refer to figure 1 : A thermoplastic precision forming nitrogen protection anti-oxidation system is mainly composed of billet purification treatment, nitrogen dynamic sealing heating and cooling non-oxidation device, medium temperature cooling and control system: the billet 9 after sandblasting, blanking, and water removal enters a heating protection Nitrogen chamber 13, the blank 15 after primary heating, and then through the preforming process 16, the preformed workpiece 17 enters the secondary heating protection nitrogen chamber 19, and the workpiece 21 after the secondary heating, undergoes the fine forming process 22, fine The formed workpiece 23 enters the cooling channel to protect the nitrogen chamber 28 , and enters the intermediate temperature cooling chamber 34 after being cooled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com