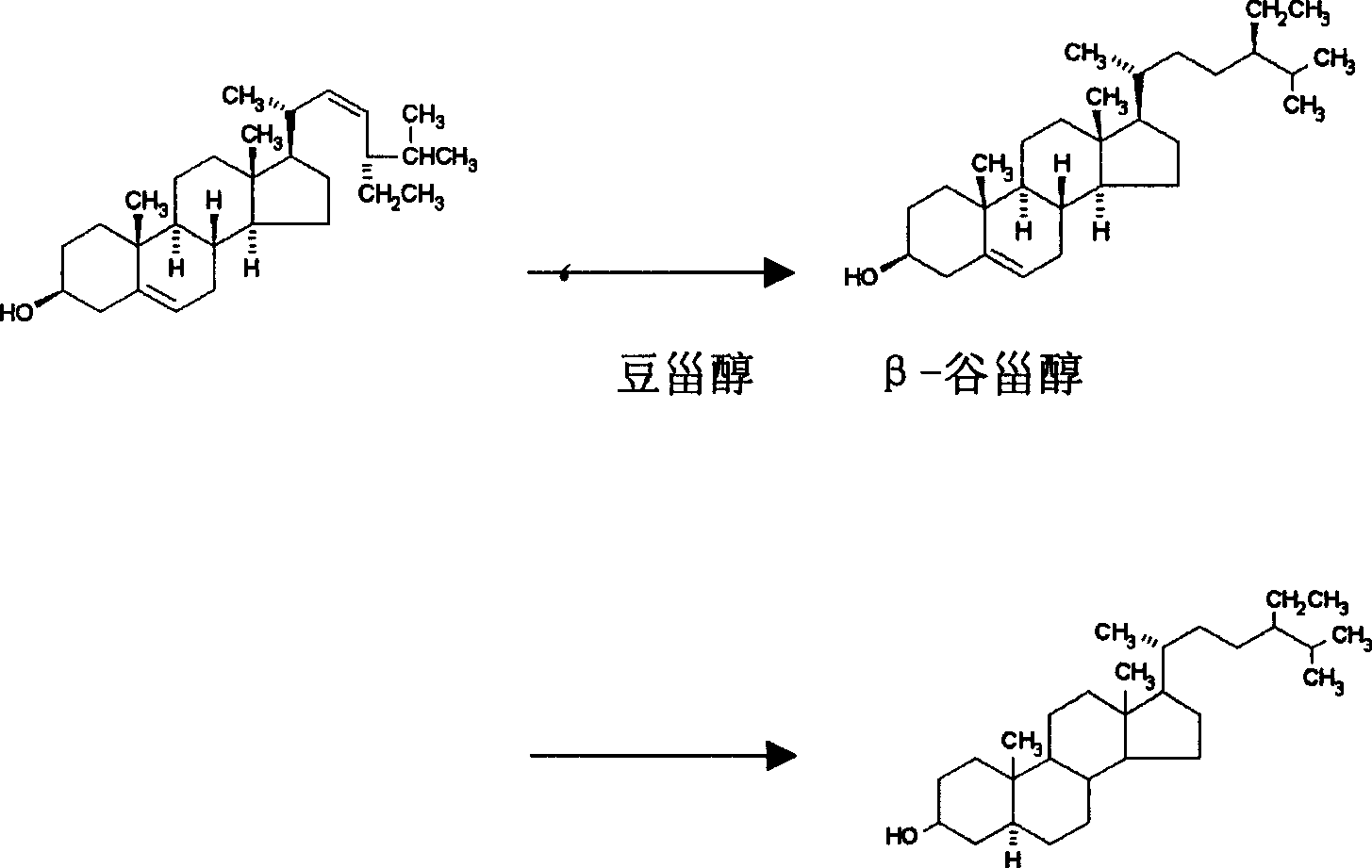

Method for preparing sitostamol

A technology for sitostanol and stigmasterol, which is applied in the field of preparation of sitostanol, achieves the effects of reducing raw material cost, simple and easy industrialized production, and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add reaction solvent isopropanol 250ml (3.2mol), 10%Pd / C catalyst consumption: 0.2% (336.8mg) of stigmasterol in the three-necked glass flask that reflux condenser is housed, heat up to 65 ℃, pass into Hydrogen, ventilation rate is 350ml / min, heat preservation and activation for 0.5h. The temperature was raised to 82° C., 16.84 g (0.04 mol) of stigmasterol was added, the reaction pressure was 101 kPa, the reaction was carried out for 10 h, and the reaction conversion rate was 95.71%. 10% Pd / C catalyst: industrial product, produced by Changzhou Kefeng Chemical Reagent Factory.

Embodiment 2

[0039] The reaction medium is ethanol, the reaction temperature is 78° C., the other conditions are the same as in Example 1, and the reaction conversion rate is 86.30%.

Embodiment 3

[0041] The reaction medium is n-butanol, the reaction temperature is 90° C., the other conditions are the same as in Example 1, and the reaction conversion rate is 92.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com