Poly-3,4-ethylenedioxy thiophene/multi-wall carbon nanotube compositions and their preparation process and use

A technology of ethylenedioxythiophene and multi-walled carbon nanotubes, which is applied in the field of poly-3,4-ethylenedioxythiophene/multi-walled carbon nanotubes composites and its preparation method and application, can solve the problems that have not yet been solved. See and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

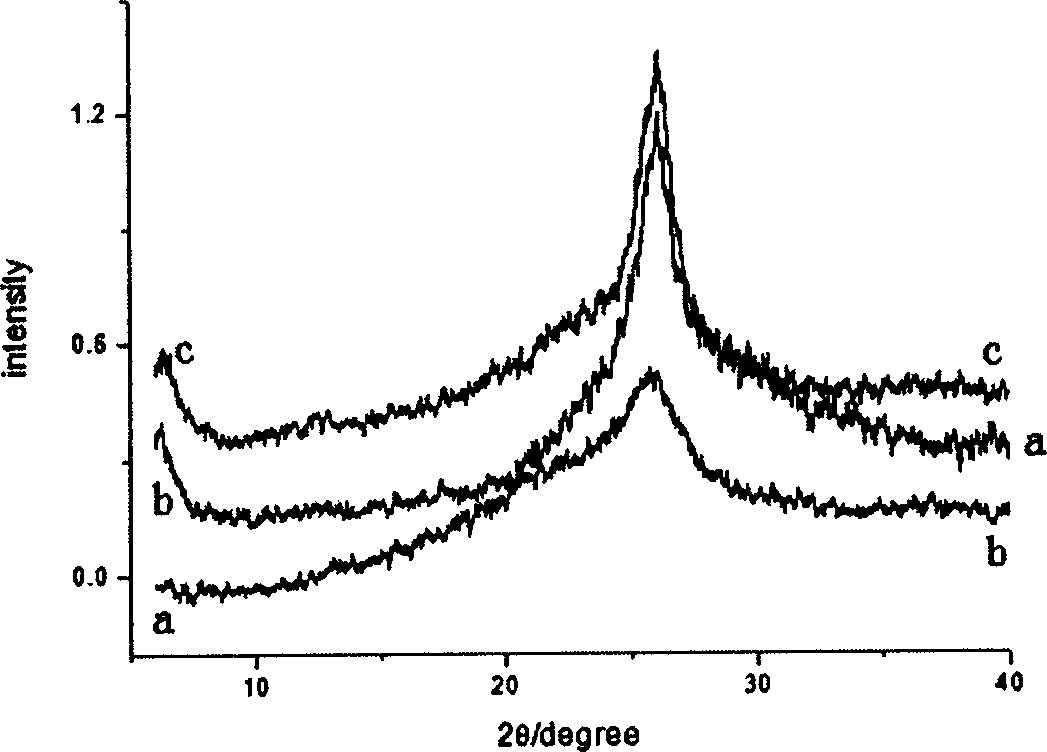

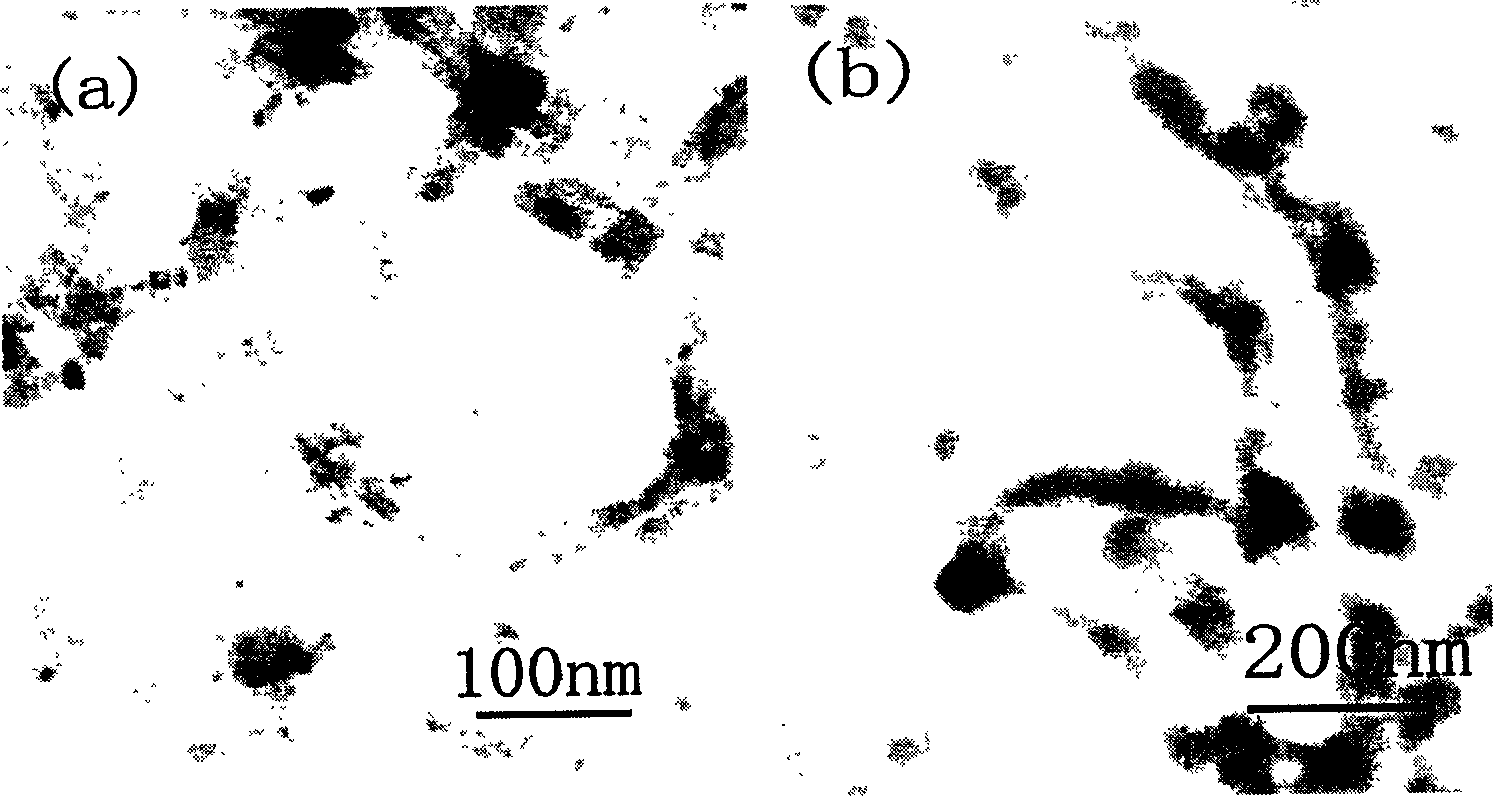

[0017] Embodiment 1. Poly-3, the preparation of 4-ethylenedioxythiophene / multi-walled carbon nanotube composite (conductive polymer poly-3, the mass of 4-ethylenedioxythiophene and multi-walled carbon nanotube The ratio is 6.8:1).

[0018] Add 0.15 g of multi-walled carbon nanotubes with a diameter of 20-40 nm, 0.46 g of p-toluenesulfonic acid, 13.1 g of ferric chloride hexahydrate, and 40 mL of distilled water in a 100 mL beaker. The above-mentioned beaker was placed in an ultrasonic cleaner for 30 minutes. After fully dissolving, 1.02 g of 3,4-ethylenedioxythiophene monomer was added dropwise at room temperature under electromagnetic stirring. Electromagnetic stirring was carried out at room temperature for 36 hours. The product was filtered, and the complexes were filtered out and washed repeatedly with distilled water until the AgNO 3 No Cl in the filtrate was detected in the aqueous solution - ion. Drying under an infrared lamp can obtain the poly-3,4-ethylenedioxyth...

Embodiment 2

[0019] Embodiment 2. Poly-3, the preparation of 4-ethylenedioxythiophene / multi-walled carbon nanotube composite (conductive polymer poly-3, the mass of 4-ethylenedioxythiophene and multi-walled carbon nanotube The ratio is 68:1)

[0020] Add 0.015 g of multi-walled carbon nanotubes with a diameter of 20-40 nm, 0.46 g of p-toluenesulfonic acid, 13.0 g of ferric chloride hexahydrate, and 40 mL of distilled water in a 100 mL beaker. The above-mentioned beaker was placed in an ultrasonic cleaner for 30 minutes. After fully dissolving, 1.02 g of 3,4-ethylenedioxythiophene monomer was added dropwise at room temperature under electromagnetic stirring. Electromagnetic stirring was carried out at room temperature for 36 hours. The product was filtered, and the complexes were filtered out and washed repeatedly with distilled water until the AgNO 3 No Cl in the filtrate was detected in the aqueous solution - ion. Drying under an infrared lamp can obtain the poly-3,4-ethylenedioxythi...

Embodiment 3

[0021] Embodiment 3. The preparation of poly-3,4-ethylenedioxythiophene / multi-walled carbon nanotube composite (the mass of conductive polymer poly-3,4-ethylenedioxythiophene and multi-walled carbon nanotube The ratio is 3:1)

[0022] Add 0.20 g of multi-walled carbon nanotubes with a diameter of 20-40 nm, 0.28 g of p-toluenesulfonic acid, 8.0 g of ferric chloride hexahydrate, and 40 mL of distilled water in a 100 mL beaker. The above-mentioned beaker was placed in an ultrasonic cleaner for 30 minutes. After fully dissolving, 0.6 g of 3,4-ethylenedioxythiophene monomer was added dropwise at room temperature under electromagnetic stirring. Electromagnetic stirring was carried out at room temperature for 36 hours. The product was filtered, and the complexes were filtered out and washed repeatedly with distilled water until the AgNO 3 No Cl in the filtrate was detected in the aqueous solution - ion. Drying under an infrared lamp can obtain the poly-3,4-ethylenedioxythiophene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com