Submicron polymer active microsphere profile-control oil-displacement agent

A technology of profile control oil displacement agent and polymer, which is applied in the direction of drilling equipment, etc., can solve the problems of temperature salinity influence, limited profile control depth, weak strength, etc., achieve strong salinity resistance, meet energy demand, The effect of high ripple efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically described below in conjunction with examples.

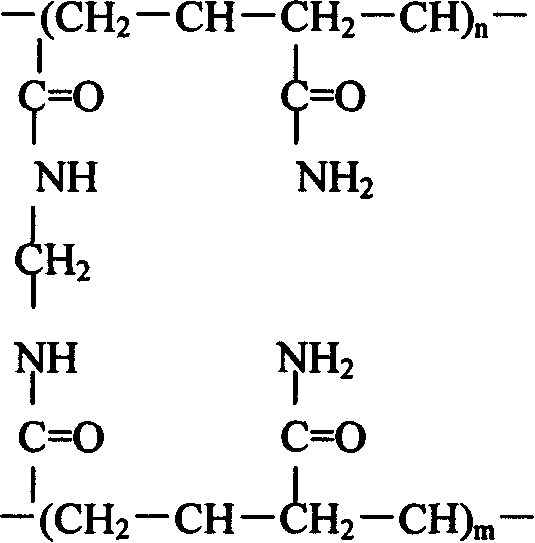

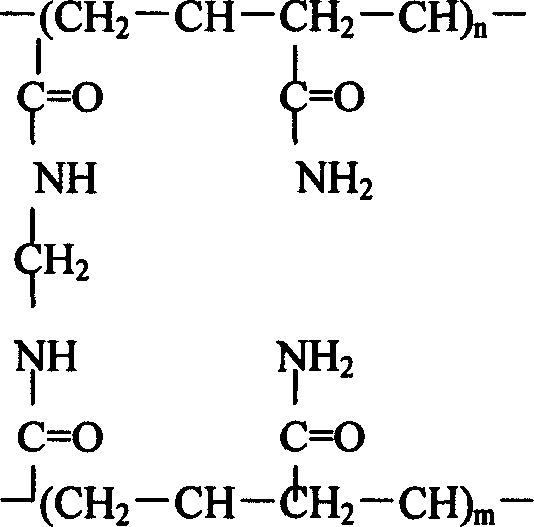

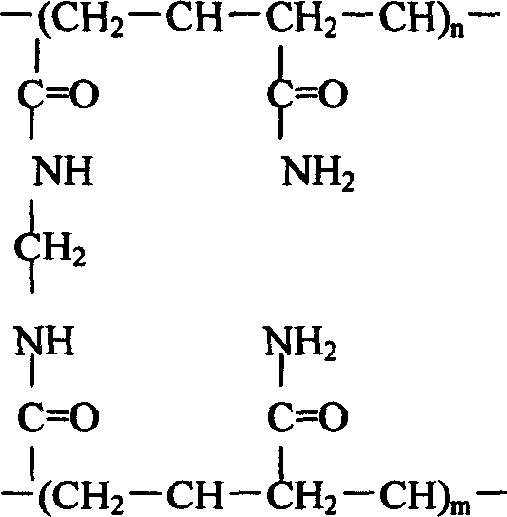

[0014] The submicron polymer active microsphere profile control and oil displacement agent provided by the present invention is an active polyacrylamide gel, and its molecular structure formula is:

[0015]

[0016] Can be synthesized by:

[0017] Take 8%~20% of acrylamide, 0.01~0.1% of methylene bisacrylamide, 0.1~0.2% of ammonium persulfate, and 1~3% of sodium dodecylbenzenesulfonate to make a solution, and heat it at 60~100℃ The solution is atomized into 0.2-20 μm micro-droplets by high-pressure spray or two-phase flow ultrasonic atomization method, and dispersed in the oil phase medium for polymerization reaction for about 1 hour to obtain submicron polymer active microspheres for oil displacement.

[0018] Microsphere particle size design principle: the permeability is 1 μm 2 The average pore diameter of the oil layer is 10.4 μm, and the permeability is 2 μm 2 The avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com