Method of separating and recovering sulfur dioxide in smoke using ammonia method

A technology for sulfur dioxide and flue gas, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of high treatment cost of absorbing liquid, difficult to eliminate aerosol, and difficult operation, and achieves easy operation, aerosol The effect of less and saving absorption liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

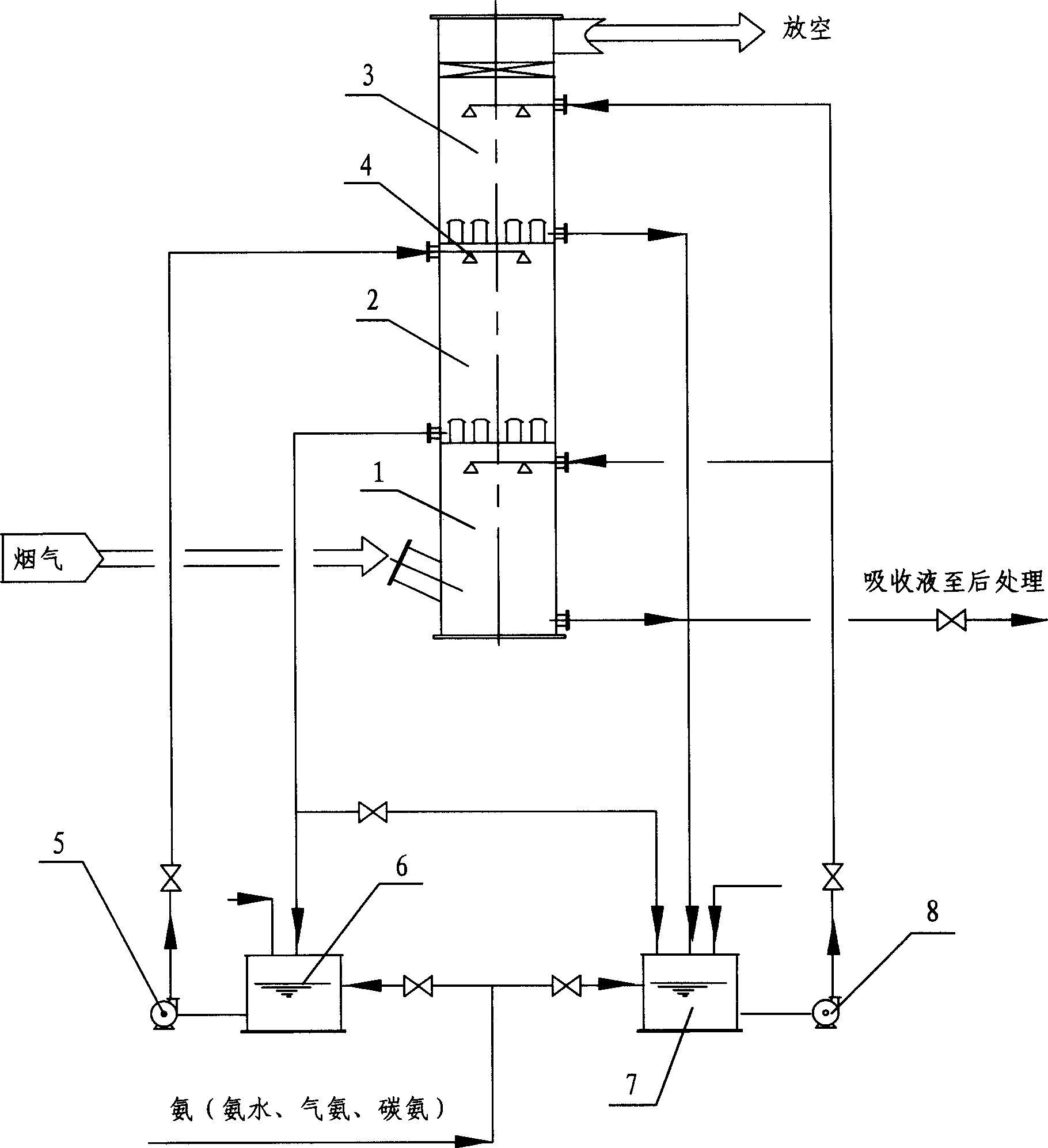

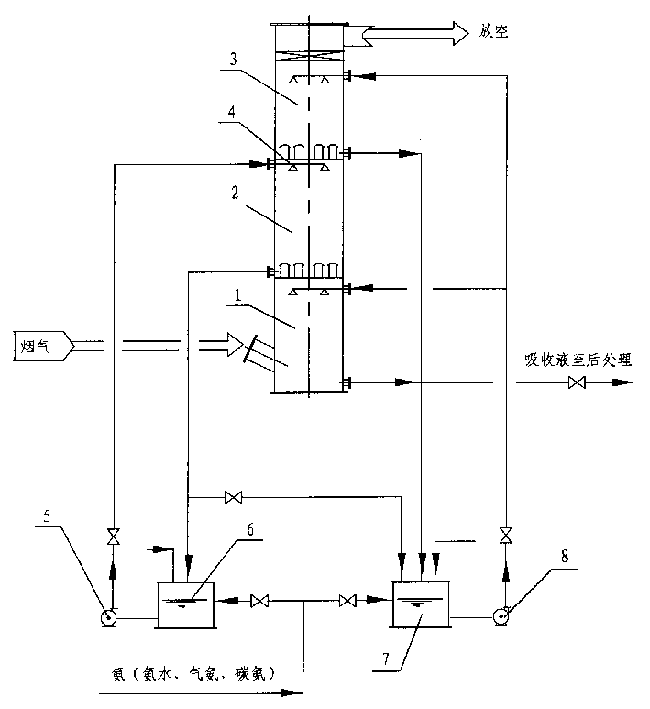

[0014] A 75t / h coal-fired industrial boiler with a flue gas volume of 110,000Nm 3 / h, boiler coal consumption 18.48t / h, coal-fired total sulfur 3%, exhaust gas temperature 170°C, original dust content 6500mg / Nm 3 , ESP efficiency is 98.5%. The desulfurization tower is φ4500×H24000. It adopts an empty tower structure and is divided into two sections and three stages of spraying. There is no filler (such as figure 1 Show).

[0015] Operating parameters:

[0016] Cooling and dust removal section—absorption liquid concentration 432g / l, alkalinity 16 titer, spray volume 120m 3 / h, the temperature of the flue gas exiting the cooling and dust removal section is 46°C.

[0017] Main absorption section—absorption liquid concentration 246g / l, alkalinity 21 titer, spray volume 120m 3 / h. .

[0018] Demist and ammonia removal section - water spray volume 12m 3 / h, the washing liquid is boiler waste water and make-up water.

[0019] result:

[0020] The by-product ammonium salt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com