High pressure connector lug for fiber enhanced thermoplastic composite plastic tube

A thermoplastic and fiber-reinforced technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of difficult composite reinforcement and affecting the use pressure of composite pipes, and achieve compact and reasonable structure and ideal heat preservation effect , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

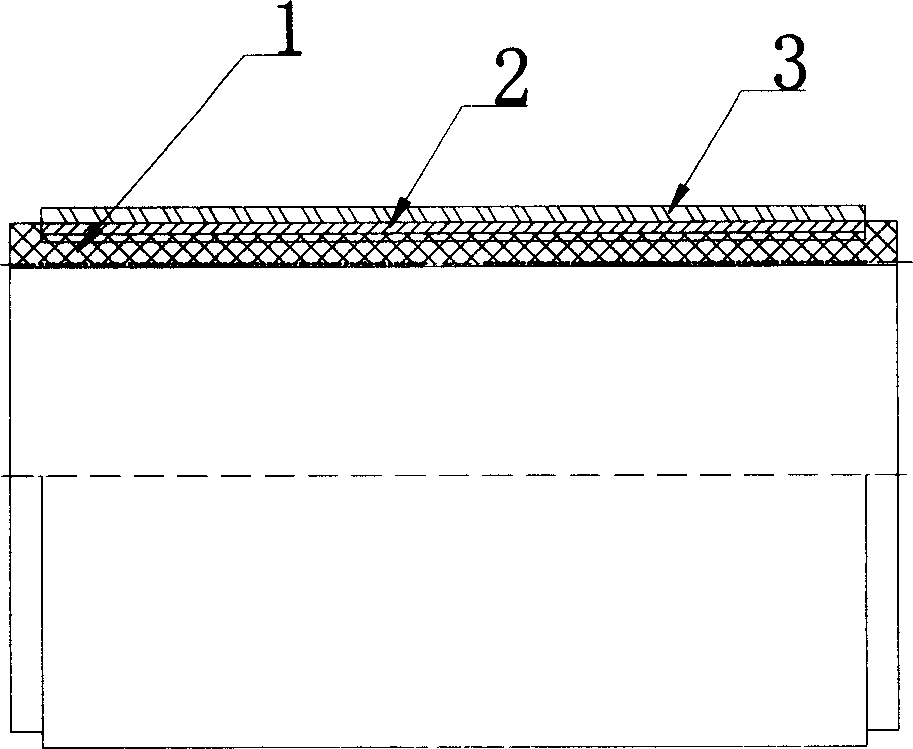

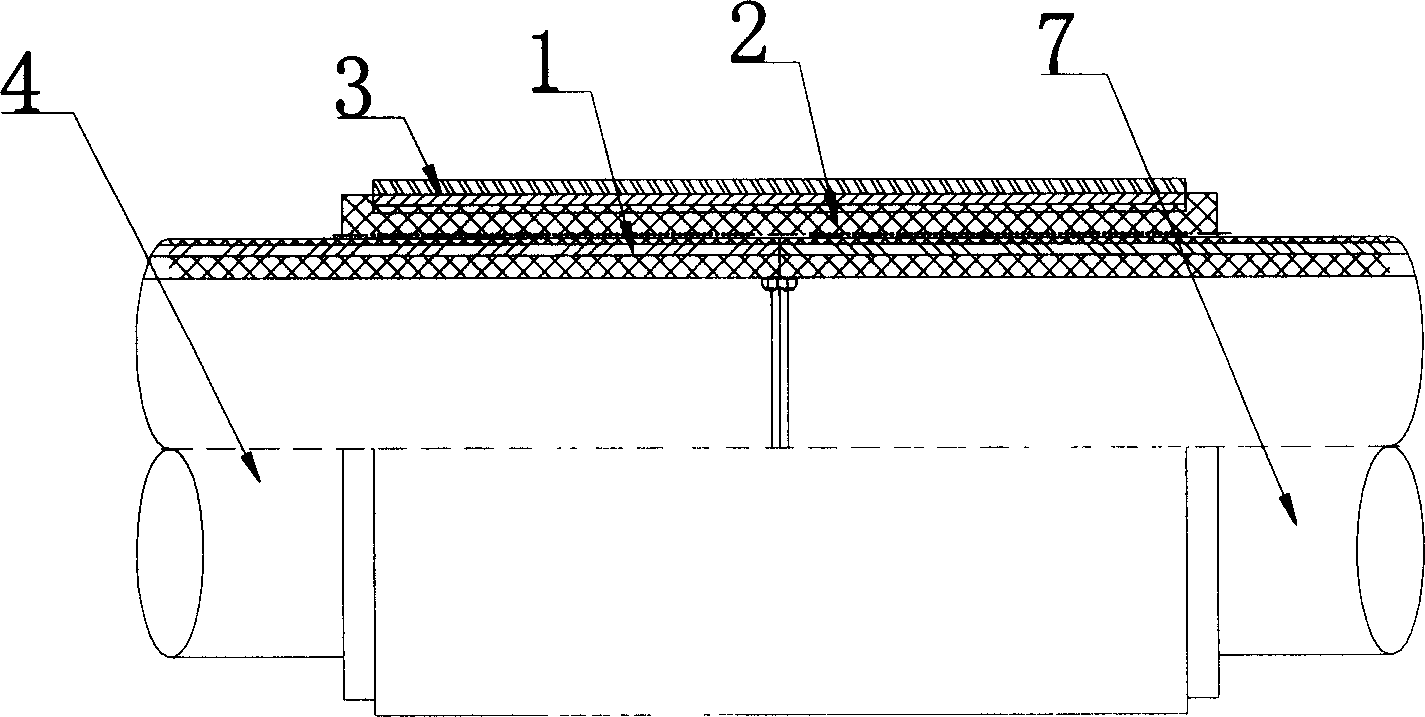

[0019] This embodiment is a fiber-reinforced thermoplastic composite pipe straight pipe high-pressure connection joint, and its structure is as follows figure 1 As shown, it is divided into three layers, the inner layer is polyolefin electrofusion sleeve 1, the middle layer is metal Huff 2 (or metal sleeve), and the outer layer is glass fiber reinforced plastic 3. The polyolefin electrofusion sleeve 1 of the inner layer realizes the connection of two fiber-reinforced thermoplastic high-pressure composite pipes 4 and 7 by electrofusion welding (see figure 2 ).

[0020] The welding melting zone of electrofusion welding bears the tensile shear stress generated by the thrust of internal pressure, but the axial strength of the inner polyolefin electrofusion sleeve 1 is limited. Under the action of internal pressure, the bearing capacity of the axial stress inside the joint The components are mainly metal Huff 2. In order to realize the transfer of axial stress from the polyolefi...

Embodiment 2

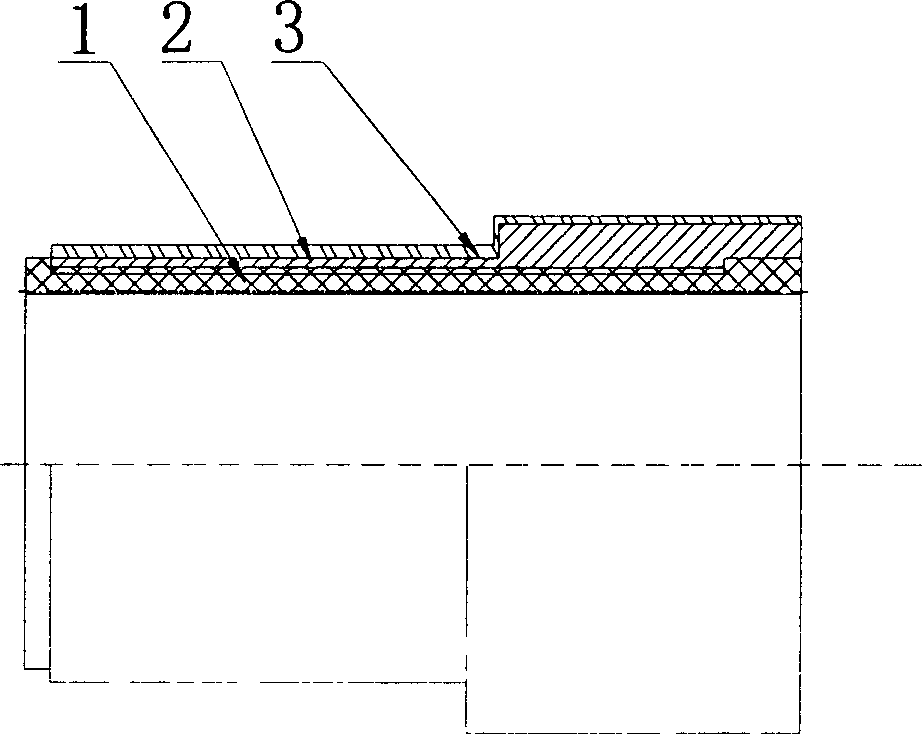

[0026] The fiber-reinforced thermoplastic composite pipe flange high-pressure connection joint of this embodiment is as follows: image 3 As shown, its basic mechanism is similar to that of the first embodiment, and it is also divided into three layers, that is, the polyolefin electrofusion sleeve 1 in the inner layer, the metal Huff or metal sleeve 2 in the middle layer, and the glass fiber reinforced plastic 3 in the outer layer. The difference is that the metal sleeve (or Huff) component is designed in the shape of a stepped shaft, and a protruding ring that can be connected to the flange is formed after winding the glass fiber reinforced plastic. Combined flanges 21 and 24 are set on the outermost layer, and the tail end is stuck at the protruding ring formed by the metal stepped shaft wound around the glass fiber reinforced plastics, and positioned axially, so that the connection with the relevant flanges 25 of other pipes or equipment 28 can be realized. connection (see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com