Method of measuring crystal defects in thin SI/SIGE bilayers

A technology for crystal defects and defects, applied in the field of semiconductor device manufacturing, can solve problems such as lack of chemical corrosion technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

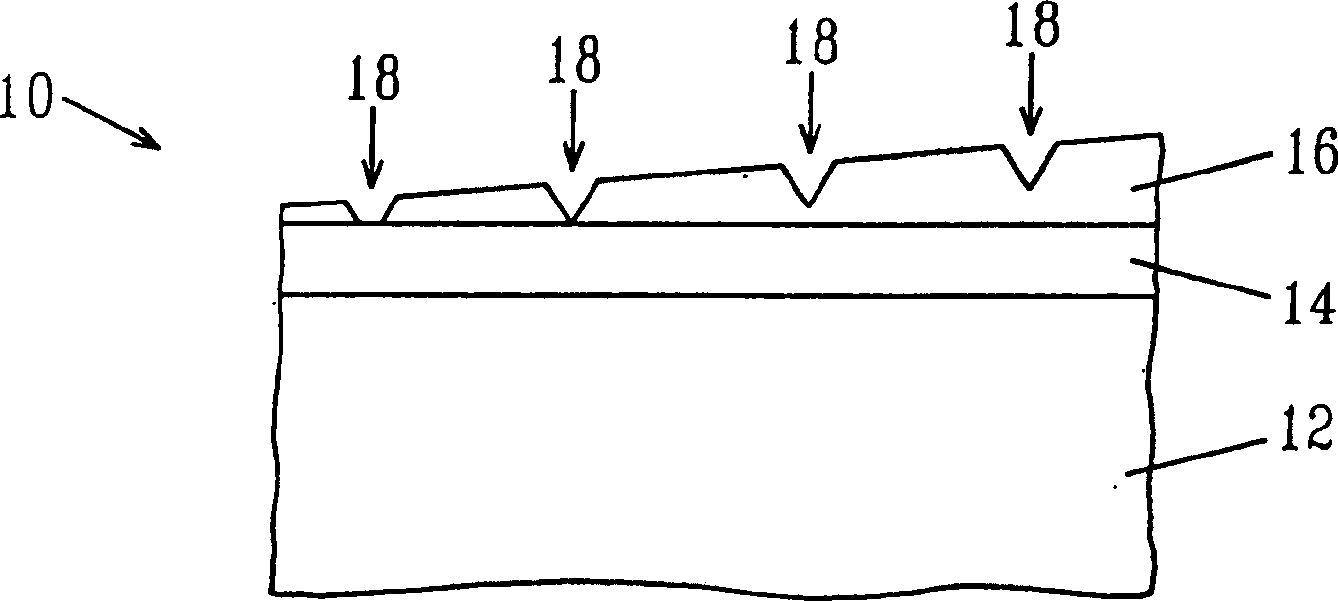

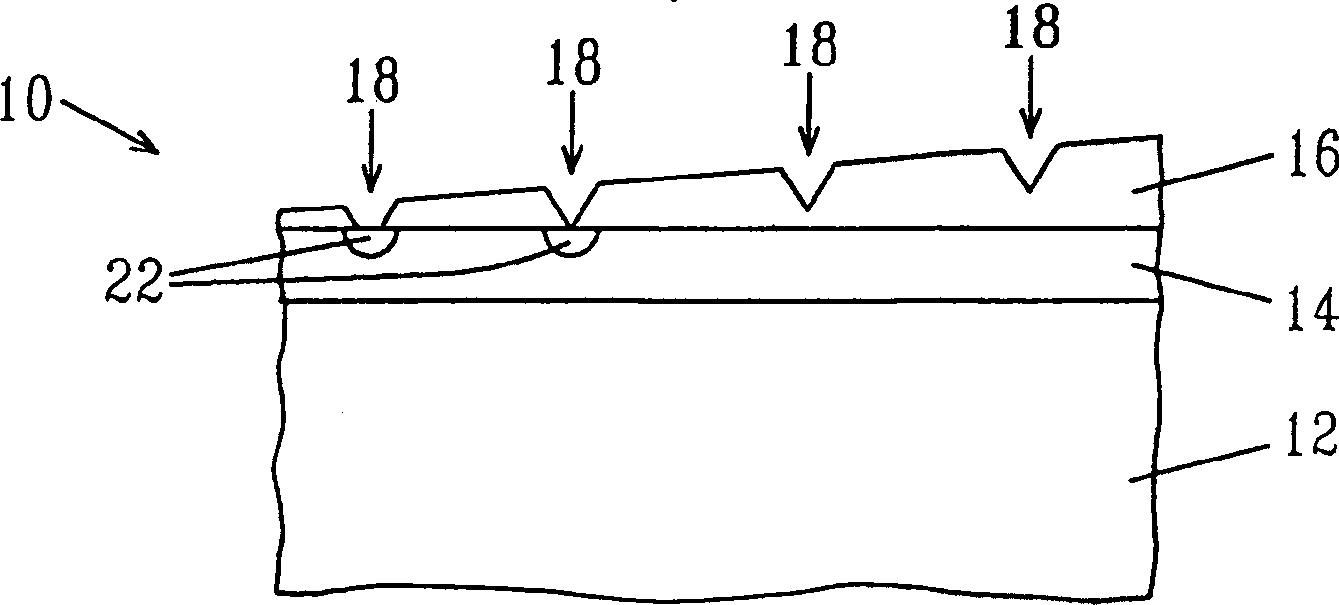

[0021] The invention will be described in more detail with reference to the drawings of the present application, which present a method for characterizing crystal defects in Si / SiGe bilayers. In the drawings, the same and corresponding elements are denoted by the same reference numerals.

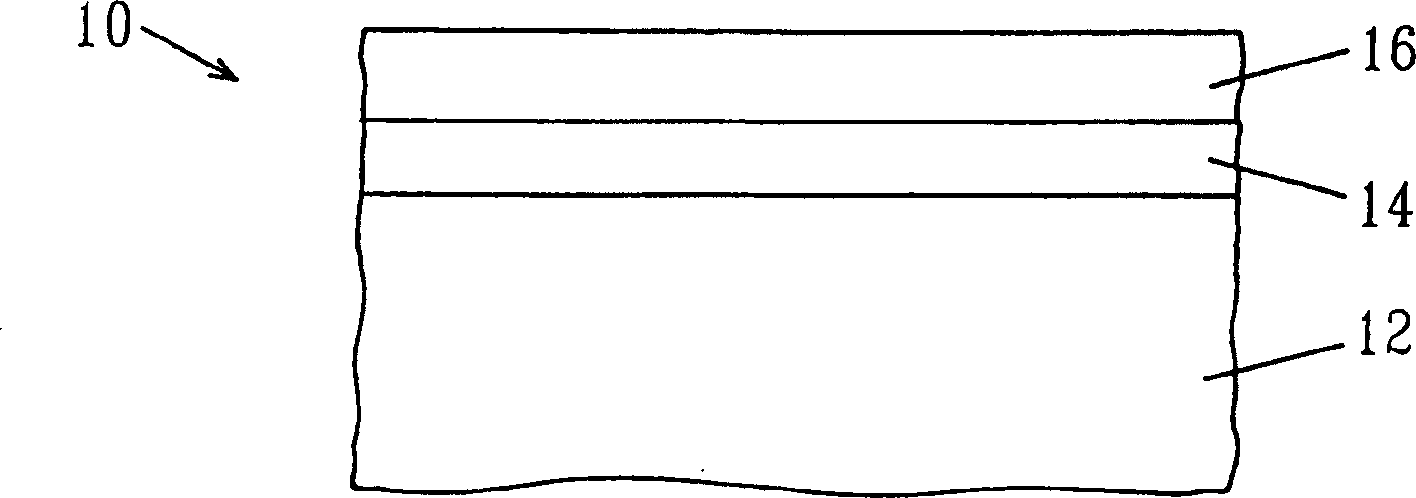

[0022] See first the present invention figure 1 The initial structure shown. Initial structure 10 includes at least Si layer 16 on top of SiGe layer 14 . Initial structure 10 also includes substrate 12 underlying SiGe layer 14 . Substrate 12 may include a bulk Si substrate or any other semiconductor substrate as well as a buried insulating region and a bottom semiconductor layer of a silicon-on-insulator (SOI) substrate; the top SOI layer of the SOI substrate has been used in the formation of the SiGe layer.

[0023] figure 1 The initial structure 10 shown is formed using methods well known to those skilled in the art. For example, the initial structure 10 may be formed by first growing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com