Starch dextrinization by dry method

A technology of starch and dry method, which is applied in the field of food processing, can solve problems such as environmental pollution, increased production costs, and decreased economic benefits of enterprises, and achieve the effects of expanding the scope of application, reducing rice losses, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

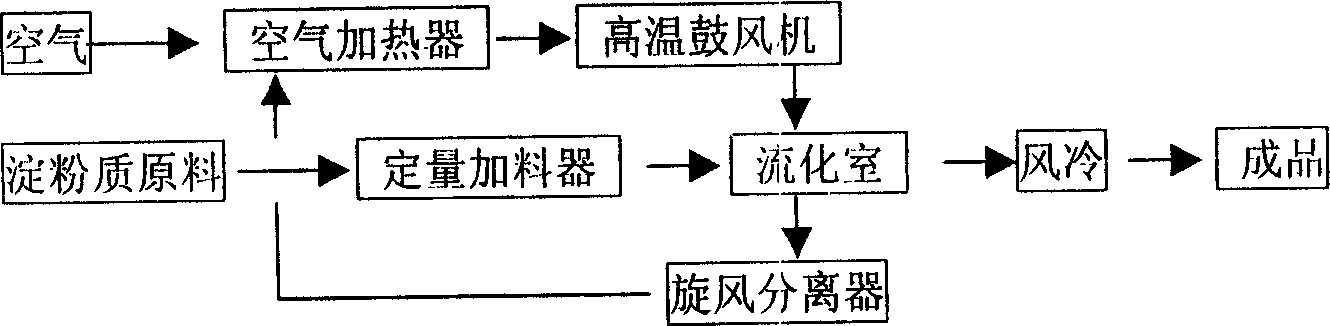

Image

Examples

Embodiment 1

[0017] First heat the air to 220°C in a 16KW electric heating tube, and use a high-temperature blower to send high-temperature hot air into the bottom of the fluidization chamber. The wind speed of the blower is 10m / s, and the volume of the fluidization chamber is 0.03 cubic meters; Continuously and evenly feed into the fluidization chamber through the quantitative feeder; and evenly fluidize in the hot air, control the contact fluidization time of rice and hot air to be 70 seconds and then be gelatinized; the gelatinized starch is discharged from the fluidization chamber and used quickly Air cool to room temperature. Rice gelatinization rate ≥ 86%. The hot air from the vulcanization chamber is separated by the cyclone separator and sent to the air heater for recycling. The dry gelatinization of the starchy raw rice produces remarkable effects, eliminates many waste water processes such as washing, soaking, cooking, water showering and cooling, facilitates the storage and tra...

Embodiment 2

[0019] First heat the air to 280°C in a 16KW electric heating tube, and use a high-temperature blower to send high-temperature hot air into the bottom of the fluidization chamber. The wind speed of the blower is 8m / s, and the volume of the fluidization chamber is 0.03 cubic meters; It is continuously and evenly fed into the fluidization chamber by a quantitative feeder; it is evenly fluidized in the hot air, and the contact fluidization time of rice and hot air is 30 seconds before it is gelatinized; the starch after gelatinization is discharged from the fluidization chamber Let cool to room temperature. Rice gelatinization rate ≥ 88%. The hot air from the vulcanization chamber is separated by the cyclone separator and sent to the air heater for recycling. The starchy raw rice also produces the remarkable effect obtained in Example 1 after the dry gelatinization of the present invention.

Embodiment 3

[0021] First, the air is heated to 300°C with a G5 gas burner, and the high-temperature hot air is sent to the bottom of the fluidization chamber by a high-temperature resistant blower. The wind speed of the blower is 8m / s, and the volume of the fluidization chamber is 0.05 cubic meters; The amount of feed is continuously and evenly added to the fluidization chamber through the quantitative feeder; and it is uniformly fluidized in the hot air, and the contact fluidization time of the rice and the hot air is controlled to be 30 seconds before it is gelatinized; the gelatinized starch is discharged from the fluidization chamber Cool quickly to room temperature with wind. Rice gelatinization rate ≥ 92%. The hot air from the vulcanization chamber is separated by the cyclone separator and sent to the air heater for recycling. The starchy raw material rice also produces the remarkable effects obtained in Examples 1 and 2 after being gelatinized by the dry method of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com