Method for preparing methanol poisoning resistant cathode catalyst of fuel cell

A cathode catalyst, fuel cell technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment approach 1

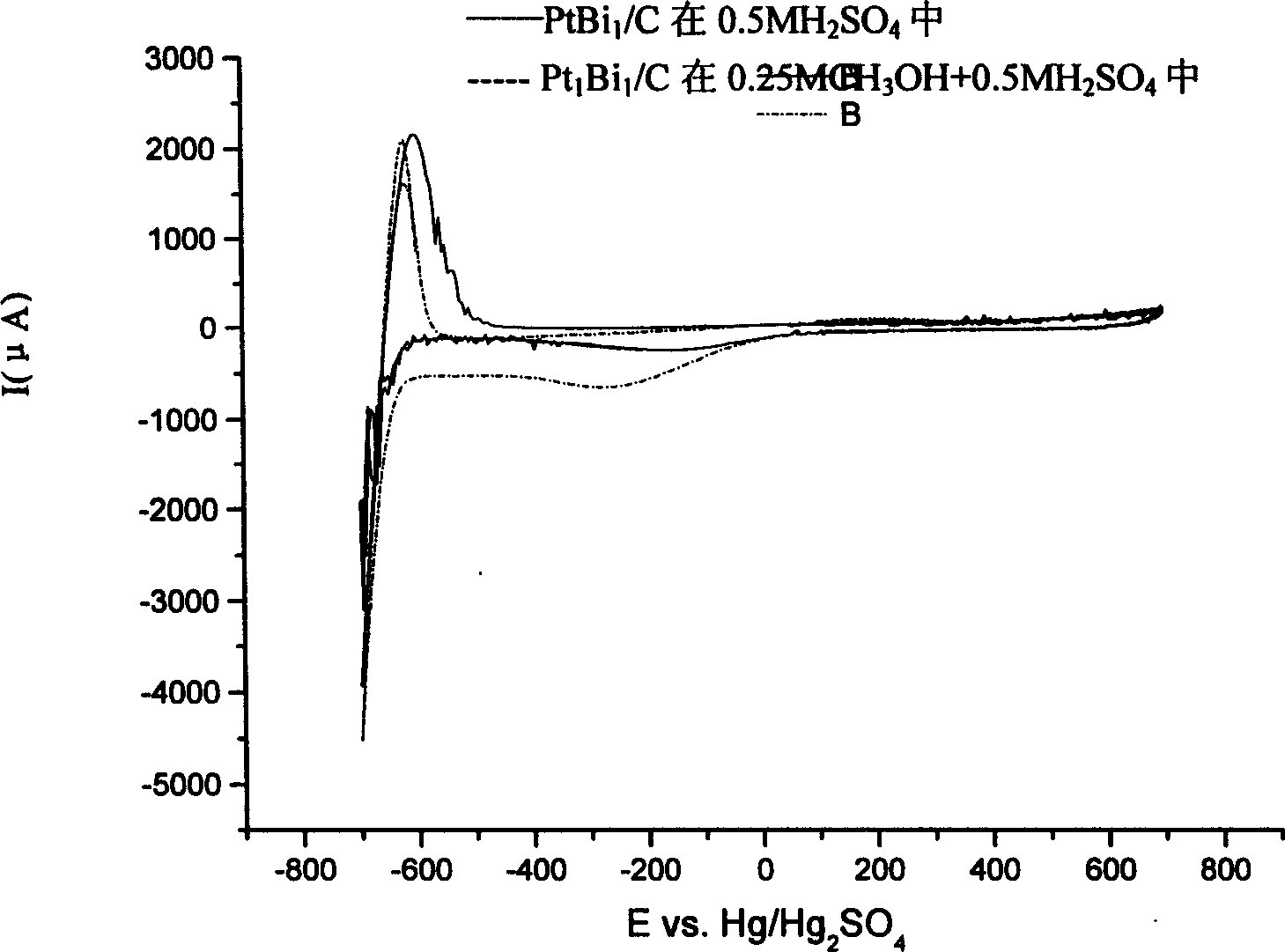

[0026] Dissolve chloroplatinic acid and bismuth chloride in 2mol / L hydrochloric acid at a molar ratio of 1:1, and add polyvinylpyrrolidone (PVP) as a protective agent, wherein the sum of polyvinylpyrrolidone, chloroplatinic acid and bismuth chloride The molar ratio is 15:1, and sodium borohydride is added under stirring conditions, wherein the molar ratio of sodium borohydride, chloroplatinic acid and bismuth chloride is 20:1, and nano-platinum-bismuth alloy and nano-platinum-bismuth metal are prepared compound sol. Add a certain amount of pretreated carbon powder into the sol and stir for several hours. The mass ratio of carbon powder to the sum of chloroplatinic acid and bismuth chloride is 4:1. After drying the sample under low pressure, use distilled water and acetone repeatedly washing and vacuum drying to obtain the carbon-supported nano-platinum-bismuth alloy and nano-platinum-bismuth intermetallic compound catalyst of the present invention.

experiment approach 2

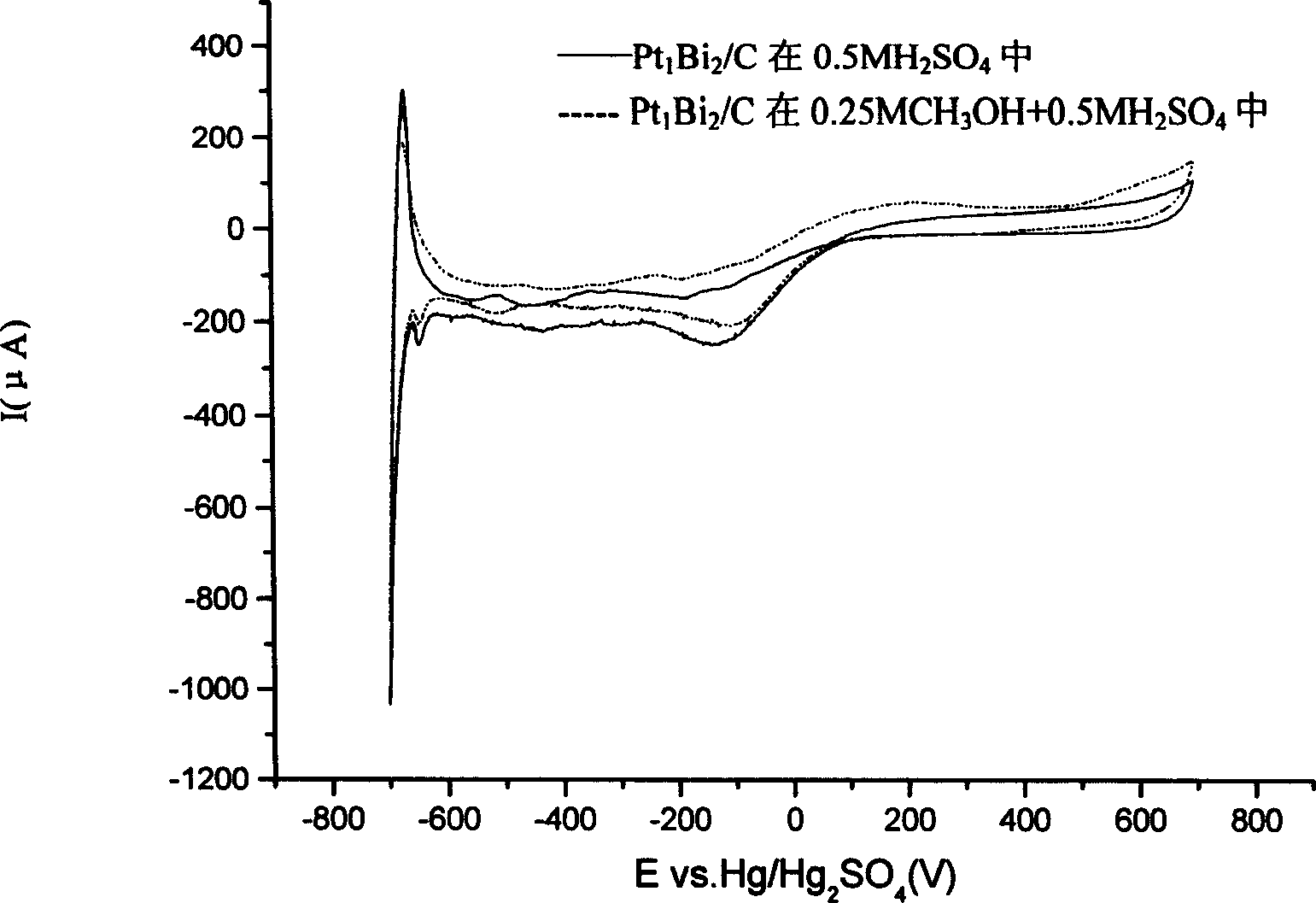

[0028] Dissolve chloroplatinic acid and bismuth chloride in 2mol / L hydrochloric acid at a molar ratio of 1:2, and add polyvinylpyrrolidone (PVP) as a protective agent, wherein the sum of polyvinylpyrrolidone, chloroplatinic acid and bismuth chloride The molar ratio is 15:1, and sodium borohydride is added under stirring conditions, wherein the molar ratio of sodium borohydride, chloroplatinic acid and bismuth chloride is 20:1, and nano-platinum-bismuth alloy and nano-platinum-bismuth metal are prepared compound sol. Add a certain amount of pretreated carbon powder into the sol and stir for several hours. The mass ratio of carbon powder to the sum of chloroplatinic acid and bismuth chloride is 4:1. After drying the sample under low pressure, use distilled water and acetone repeatedly washing and vacuum drying to obtain the carbon-supported nano-platinum-bismuth alloy and nano-platinum-bismuth intermetallic compound catalyst of the present invention.

experiment approach 3

[0030]Dissolve chloroplatinic acid and bismuth chloride in 2mol / L hydrochloric acid at a molar ratio of 1:5, and add polyvinylpyrrolidone (PVP) as a protective agent, wherein the sum of polyvinylpyrrolidone, chloroplatinic acid and bismuth chloride The molar ratio is 15:1, and sodium borohydride is added under stirring conditions, wherein the molar ratio of sodium borohydride, chloroplatinic acid and bismuth chloride is 20:1, and nano-platinum-bismuth alloy and nano-platinum-bismuth metal are prepared compound sol. Add a certain amount of pretreated carbon powder into the sol and stir for several hours. The mass ratio of carbon powder to the sum of chloroplatinic acid and bismuth chloride is 4:1. After drying the sample under low pressure, use distilled water and acetone repeatedly washing and vacuum drying to obtain the carbon-supported nano-platinum-bismuth alloy and nano-platinum-bismuth intermetallic compound catalyst of the present invention.

[0031] Preparation method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com