Semiconductor laser side-face pumping solid strip laser

A slab laser and side-pumped technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problem of inability to achieve high-power laser output, complex laser solid slab processing technology, and inability to guarantee high power Output and other issues, to achieve the effect of small thermal stress, small thermal distortion, and reduced thermal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

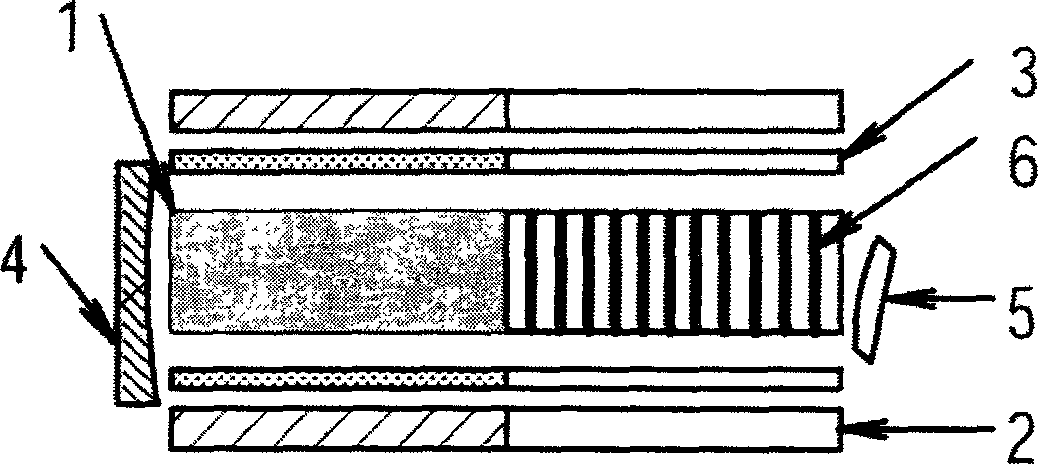

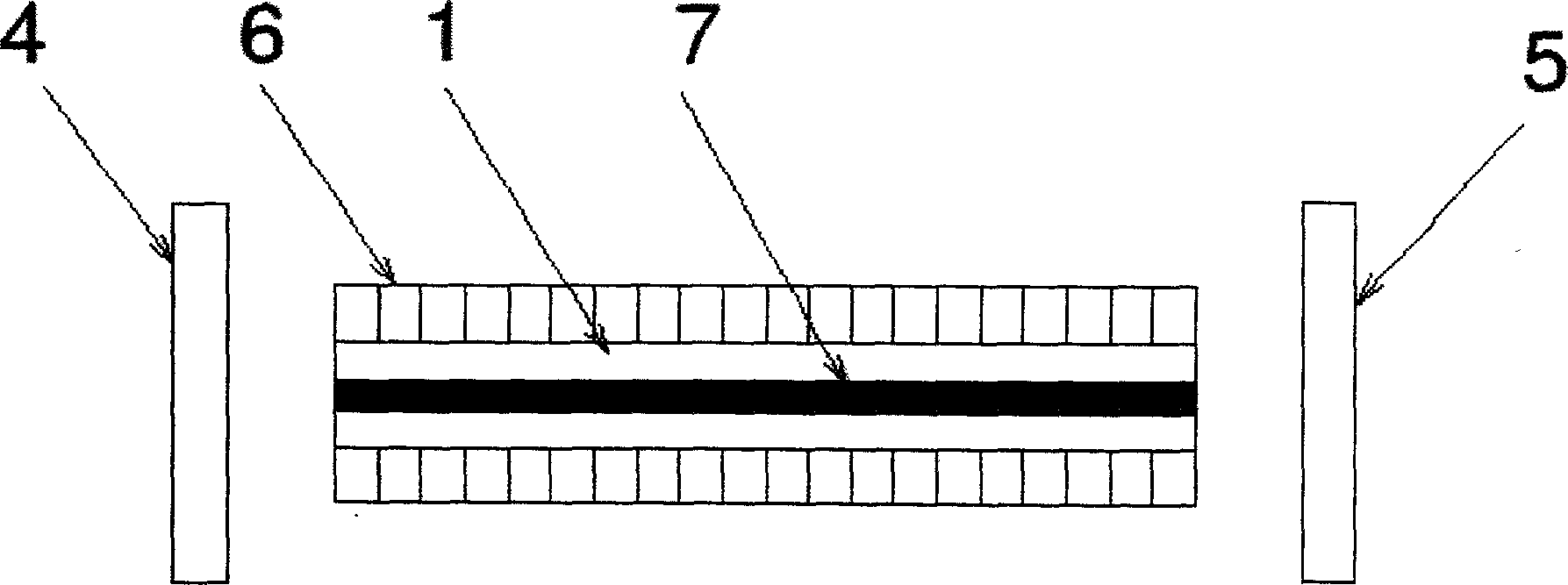

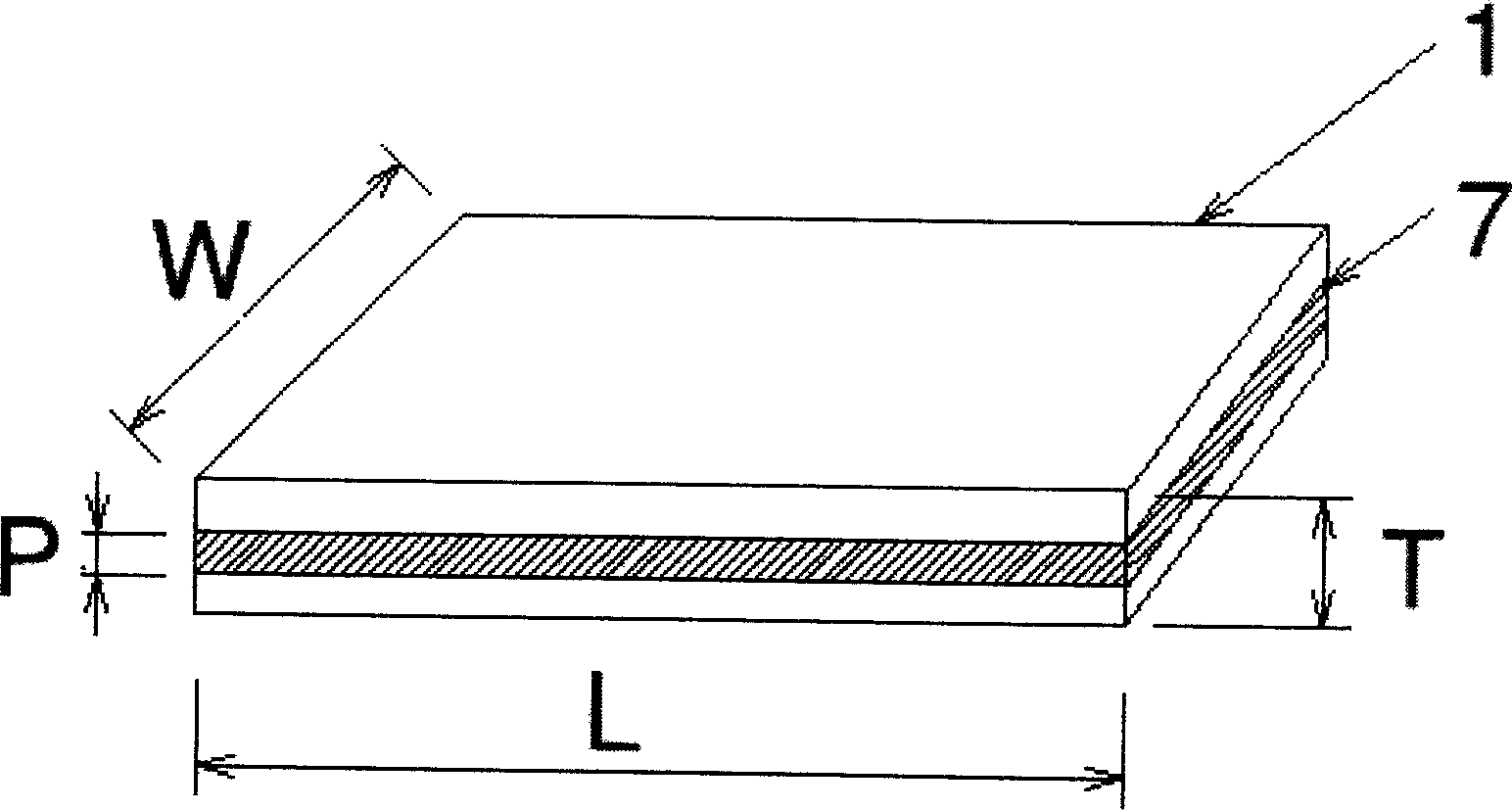

[0022] see figure 1 , figure 2 with image 3 As shown, it can be seen from the figure that a solid slab laser pumped by the side of a semiconductor laser is composed of a laser solid slab 1, a semiconductor laser pump source 2, an optically shaped cylindrical microlens 3, a rear cavity mirror 4 of the laser resonator, The output mirror 5 of the laser resonator and the cooler 6 are composed. The laser solid slat 1 is a sheet slat of a single structure, and a semiconductor laser pumping source 2 is arranged on both sides, that is, in the width direction, and the optical shaping cylindrical microlens 3 is located between the semiconductor laser pump source 2 and the laser solid slab 1, the pump light emitted by the semiconductor laser pump source 2 passes through the optically shaped cylindrical microlens 3 to form a one-dimensional parallel light with a rectangular cross section, from The middle position of the side of the laser solid slab 1 enters, the beam diameter of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com