Heating system and automat

A vending machine and heating system technology, applied to lighting and heating equipment, machines using waste heat, heat pumps, etc., can solve problems such as refrigerant condensation retention, insufficient refrigerant, and low temperature of the compressor 418

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

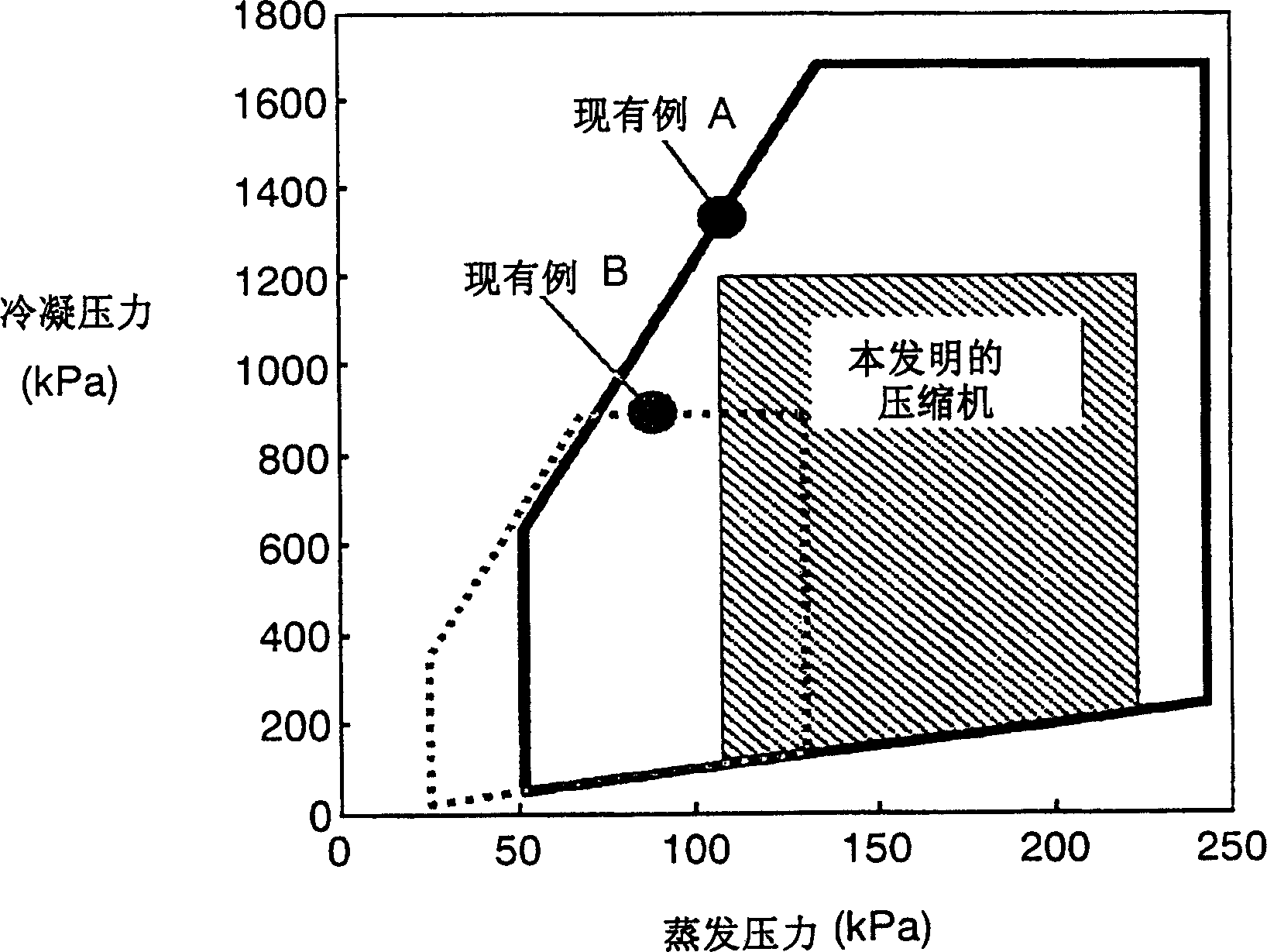

[0138] In the above-mentioned existing structure, while heating the heat / cold switching chamber, the cooling dedicated chamber and the second cooling dedicated chamber are cooled. Therefore, it is necessary to simultaneously achieve a cold shrinkage temperature above 60°C and an evaporation temperature of -10°C. Under the condition below ℃, it is necessary to develop this kind of compressor for medium and low temperature resistant to the condition of high compression ratio, which has become a problem.

[0139] Generally speaking, compressors for refrigeration and air-conditioning are low-temperature compressors suitable for evaporating temperatures of -30 to -20°C and low-temperature compressors suitable for evaporating temperatures of -10 to +10°C and high-temperature compressors for air conditioning. There is a big difference between the machine and the medium temperature compressor suitable for the evaporation temperature between them -20 ~ -10 ℃. In the vending machine in ...

Embodiment approach 2

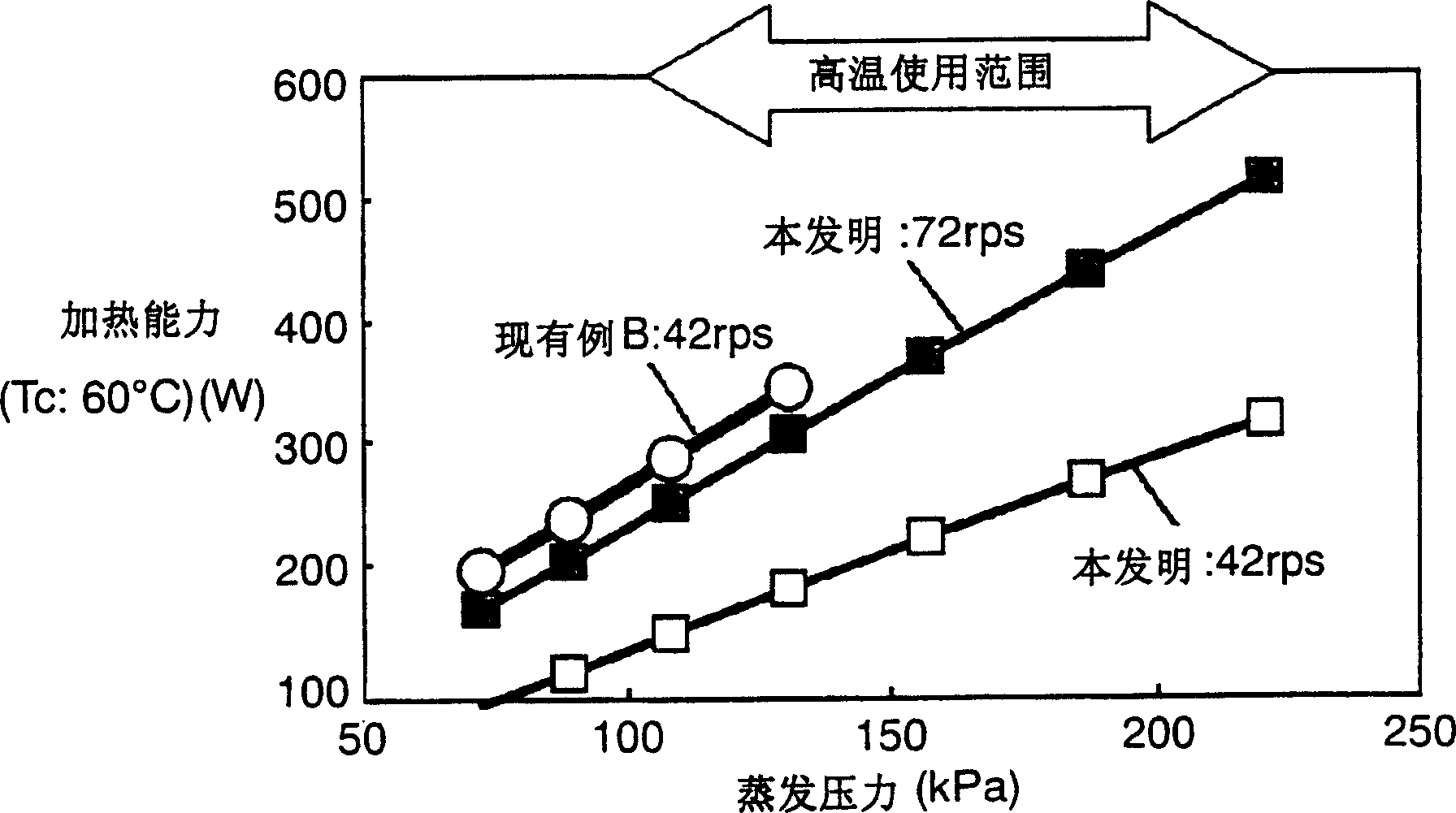

[0187] In the above existing structure, it is assumed that the relatively low condensation temperature of the heat pump of the air conditioner is about 30-40°C, and when the product such as canned beverages is heated to 50-100°C, the condensation pressure becomes high, and the high condensation temperature is high. Under pressure, in order to ensure low solubility of hydrocarbon refrigerants, it is necessary to maintain a higher temperature of mineral oil-based lubricating oil. Therefore, the heating power required to maintain the high temperature of the high-pressure shell compressor 201 increases, and at the same time, the amount of heat leaked to the outside during heating also increases, resulting in a significant reduction in efficiency. In order to ensure the necessary viscosity of lubricating oil at high temperature, when lubricating oil with higher viscosity is used, the lubricating oil discharged into the system piping together with the refrigerant will have an abnorma...

Embodiment approach 3

[0242] Figure 11 It is a refrigerant circuit diagram of the automatic vending machine of Embodiment 3. Figure 12 It is a time chart of heating control of the automatic vending machine of Embodiment 3.

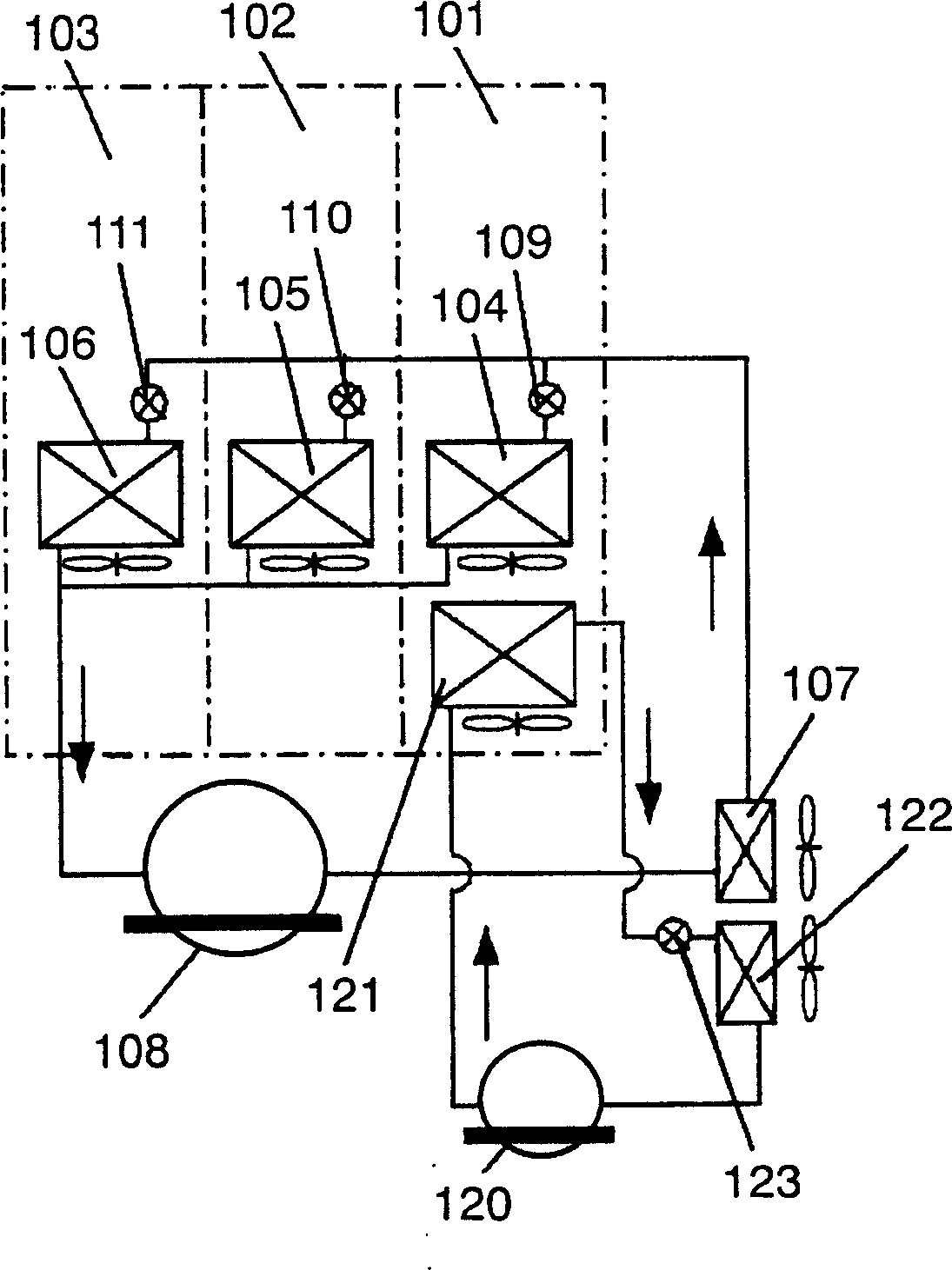

[0243] Such as Figure 11 As shown, the automatic vending machine of the present invention has a storage room composed of a hot / cold switching room 301, a cooling dedicated room 302, and a second cooling dedicated room 303, and has a heat pump system for heating the hot / cold switching room 301 exclusively. The heat pump system includes a heating compressor 320 , a switching chamber condenser 321 installed in the heat / cool switching chamber 301 , a switching chamber evaporator 322 installed outside the storage, and a heating expansion valve 323 .

[0244] In order to assist in completing the heating capacity of the heat pump system, a heater 324 is arranged on the lower side of the air path of the condenser 321 in the switching chamber. heating capacity. The air heated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com