High-heat radiation and low-noise circuit board

A low-noise, high-heat-dissipation technology, applied in printed circuits, electrical components, magnetic/electric field shielding, etc., can solve the problems of increasing space, weight and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

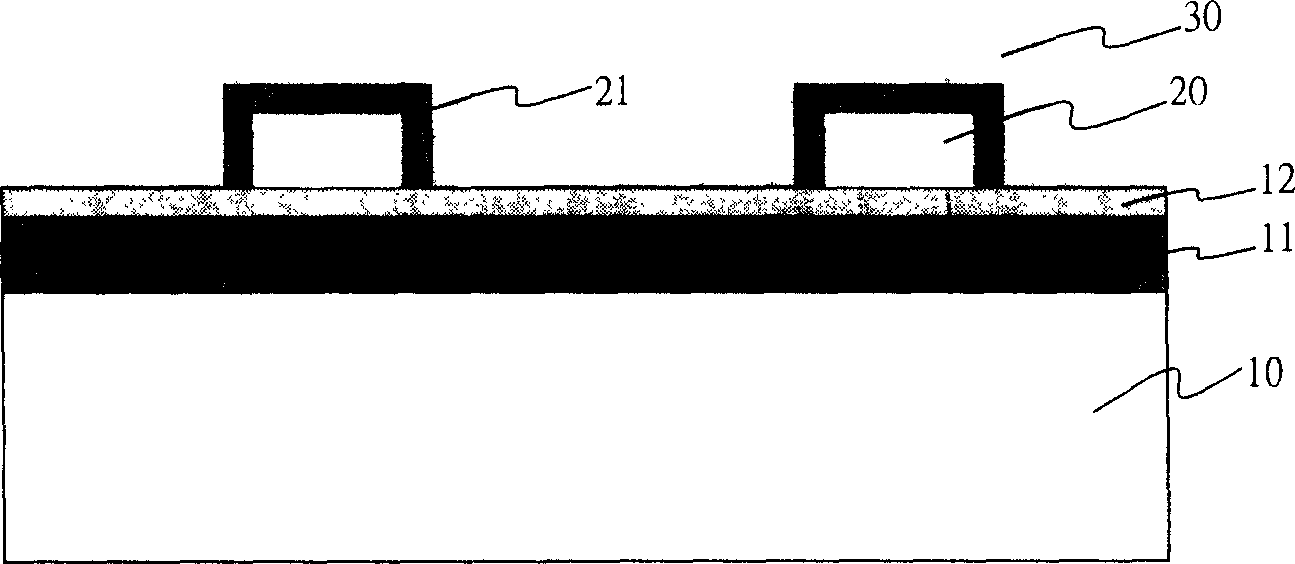

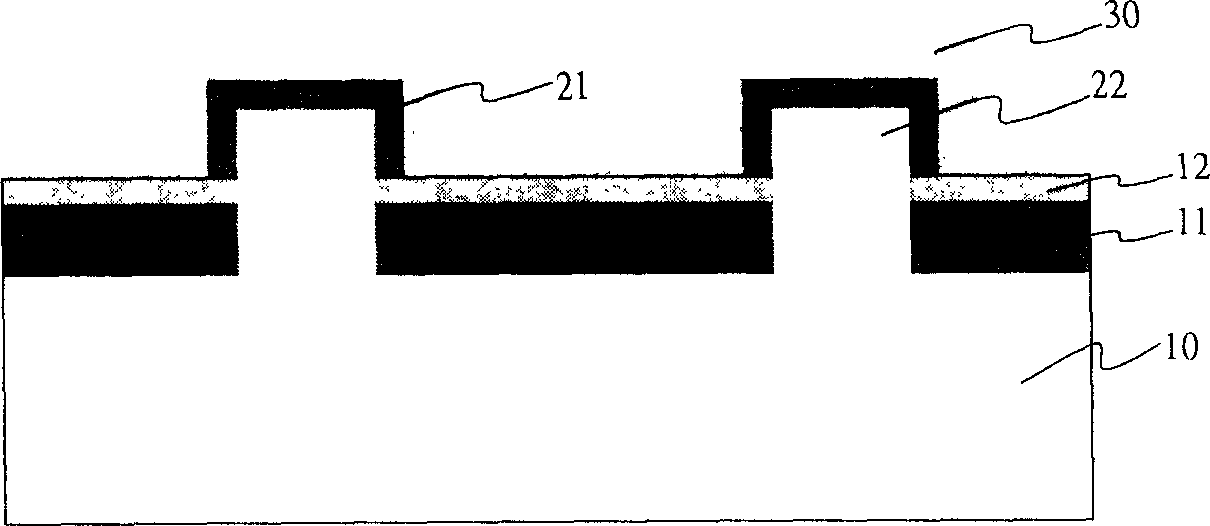

[0043] The circuit board with high heat dissipation and low noise disclosed by the present invention makes the cooling speed of the circuit board faster through the structural design of the substrate, isolates electromagnetic interference phenomena, and avoids the use of adhesives.

[0044] Its circuit board structure uses metal plates as the base material of the circuit board. With the design of the substrate structure, the buffer surface with micro-holes is used to increase the adhesion of the insulating layer, and a metal covering layer is added to the structure. Its characteristic is that the entire metal substrate can be used to transmit the heat generated by the components, increasing the surface area for heat dissipation. The buffer surface of the insulating layer can increase the adhesion of the circuit layer to save the use of adhesives. Adding a metal covering layer in the circuit board structure can more effectively isolate electromagnetic interference phenomena. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com