Exhausting humidity on-line monitor for steam turbine

A technology for exhaust humidity and monitoring devices, which is applied in special data processing applications, instruments, and electrical digital data processing, etc. It can solve problems such as increased flow resistance, high requirements for vacuuming equipment, and interference with the humidity of the steam to be measured. Low operating consumption, low humidity interference, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

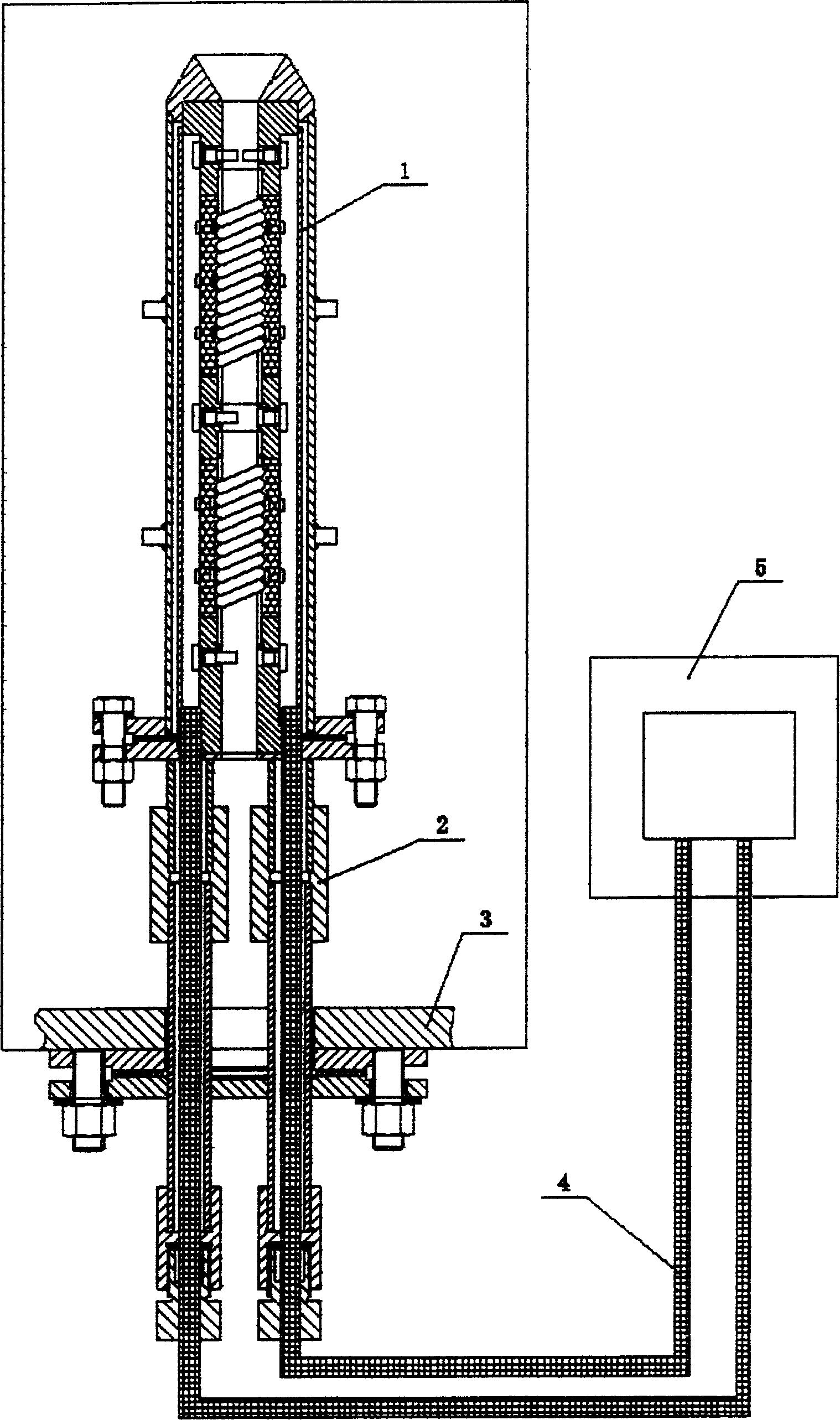

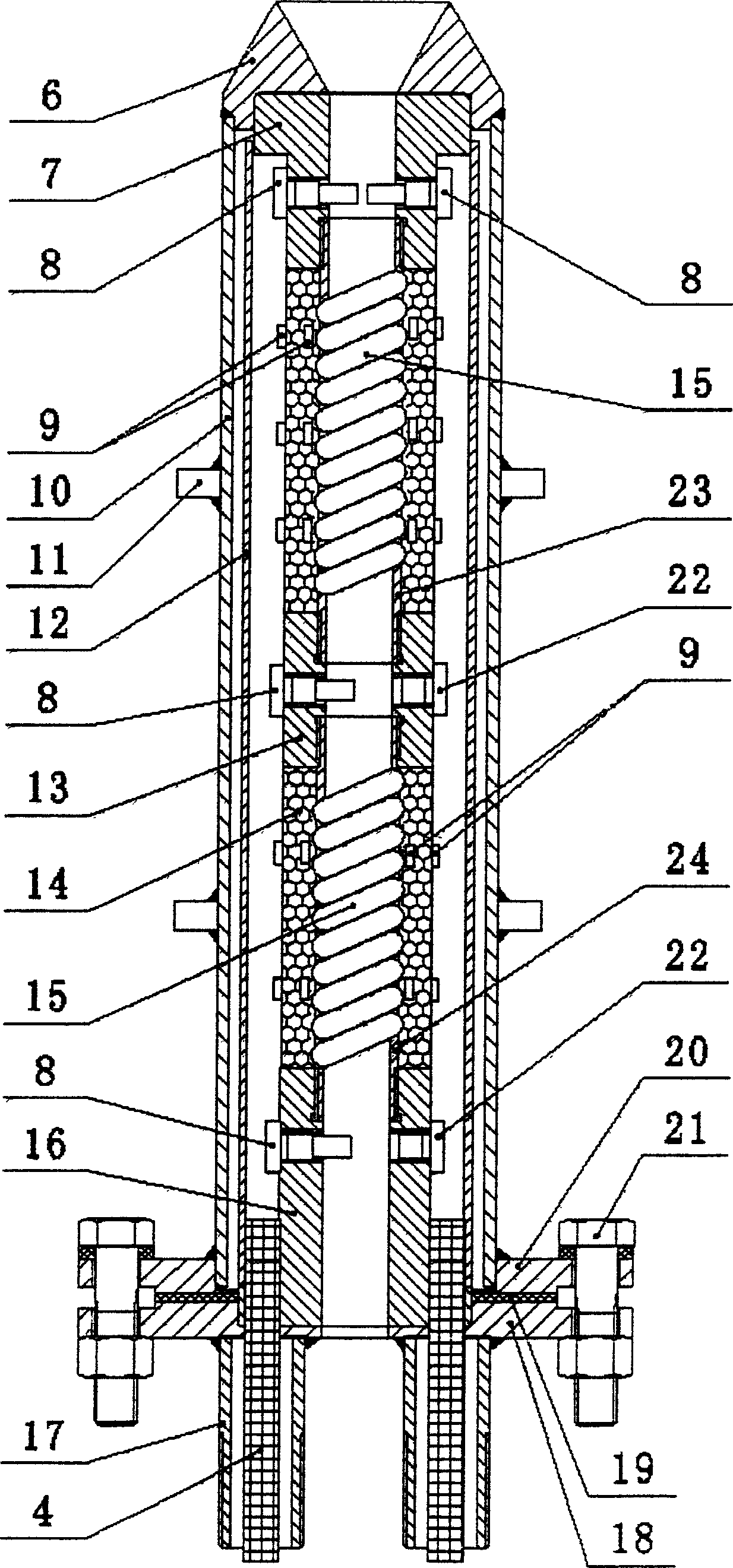

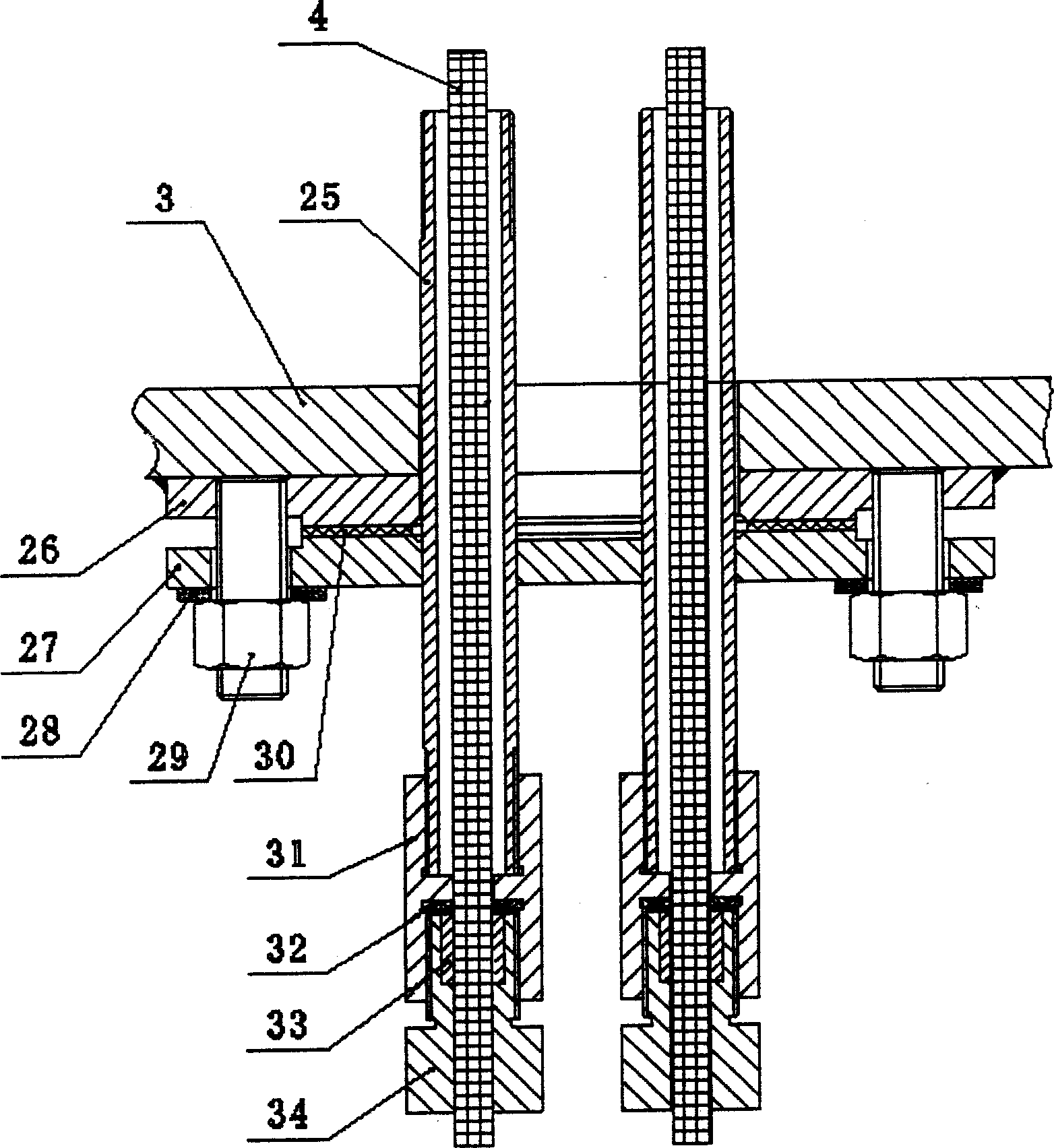

[0082] From attached figure 1 It can be seen that the steam turbine exhaust humidity online monitoring device of the present invention is located in the exhaust pipe of the low-pressure cylinder of the steam turbine, and the probe 1 and its positioning bracket 11 are welded below the sub-plane in the cylinder, so that the probe 1 is parallel to the steam turbine exhaust steam flow direction, and the probe head The part 6 is facing the direction of the incoming flow, and the probe 1 is 10-20 cm away from the last stage blade of the steam turbine. The wet steam flows freely through the probe 1, where it is heated into superheated steam. The device is mainly composed of a probe 1, a cable 4 and a cable sealing device, a data acquisition control device 5, a power supply, wires and lead wires, and the like. From attached figure 2 It can be seen that the probe 1 is provided with a heating tube 23 in the evaporating section and a heating tube 24 in the superheating section. They a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com