Warm floor

A floor warming technology, applied in floors, buildings, building structures, etc., can solve problems such as floor warpage, loss, energy waste, etc., and achieve the effects of reducing heat energy loss, low thermal expansion coefficient, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and a preferred specific embodiment, so as to facilitate a better understanding of the present invention.

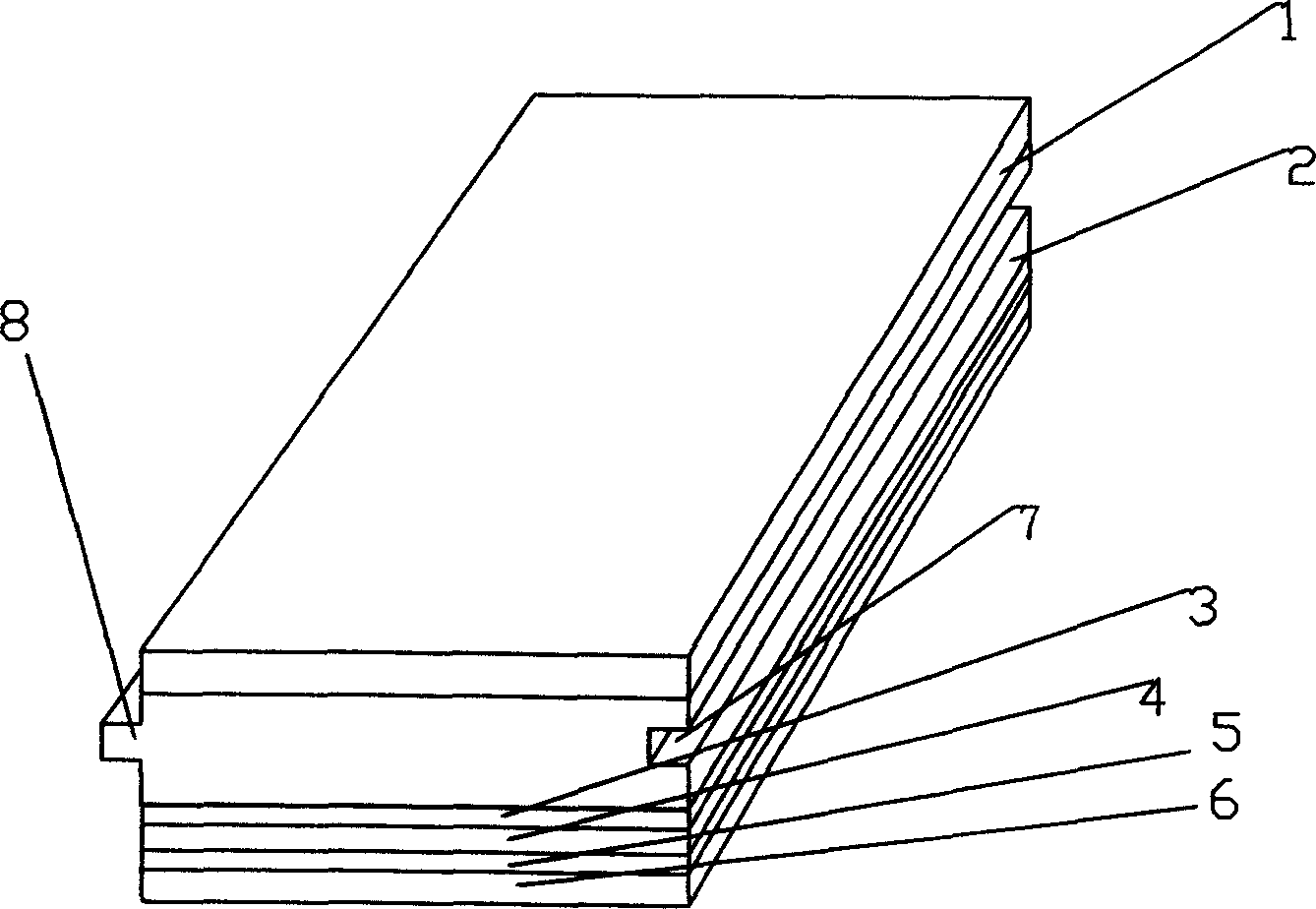

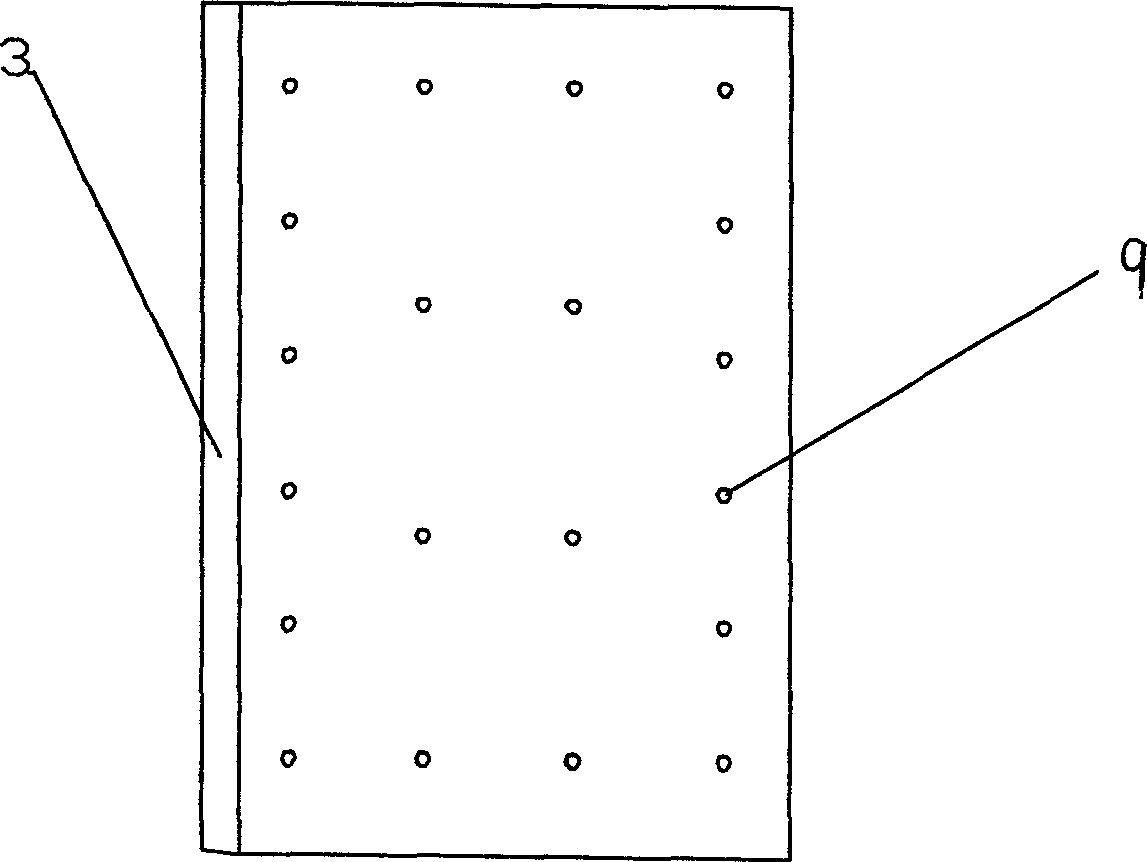

[0016] Such as figure 1 As shown, the warm floor is finished with five different materials and six layers respectively through viscose lamination. The glue adopts high-strength glue that is antifreeze and fireproof. The first layer (surface layer) of the warm floor adopts 1mm~6mm wood floor as the surface layer 1; the second layer uses 6mm~12mm ceramic substrate 2 to bond the surface layer of wood floor, and the two sides corresponding to the ceramic substrate are respectively separated. Milling tenon head 8 and tenon groove 7; the third layer uses electrothermal film floor heating sheet 3 to stick to the ceramic substrate of the second layer; the fourth layer uses 3mm~6mm magnesium oxide board as the heat insulation layer 4 to support the third layer Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com