Electro-Fenton method and apparatus for removing multi-algae toxins from water

A microcystin and water removal technology, which is applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems that algae toxins have not been reported, and achieve easy control, easy operation, and equipment compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

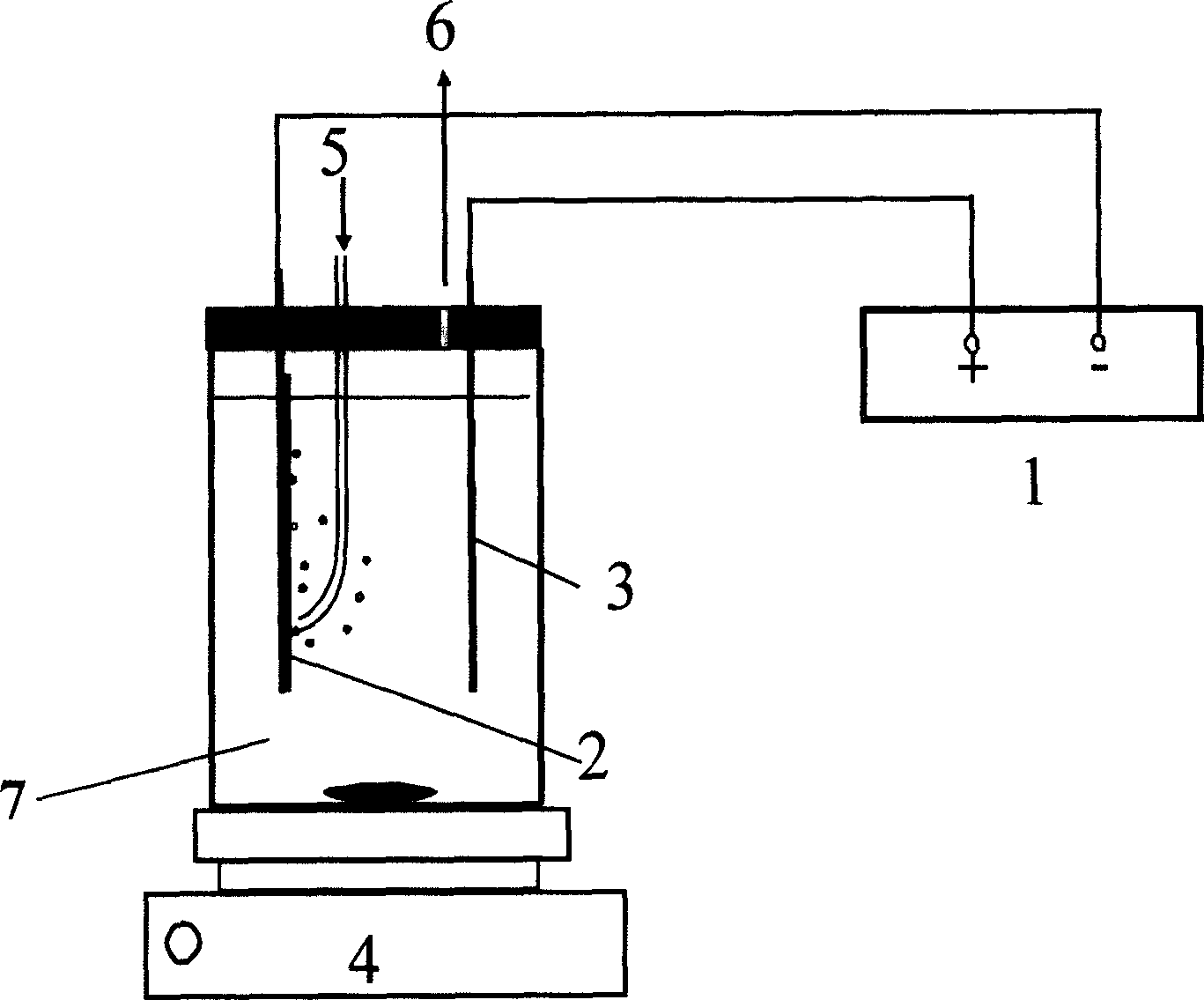

Image

Examples

Embodiment 1

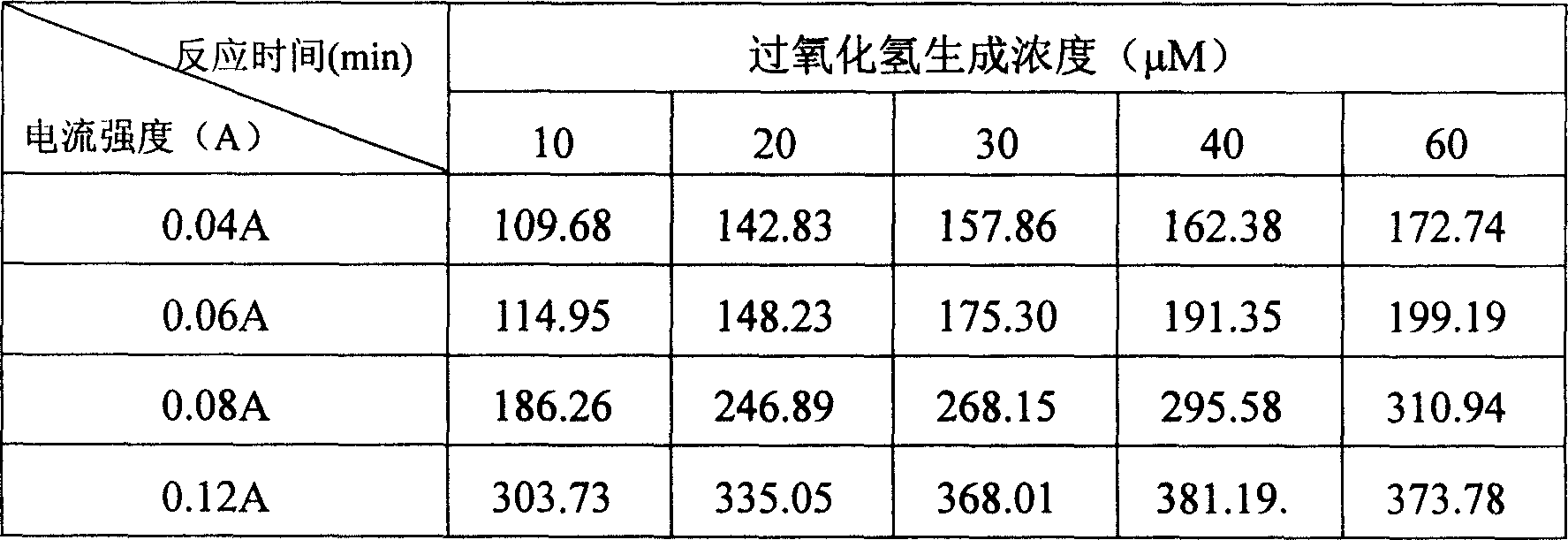

[0015] Embodiment 1. Generation of hydrogen peroxide in the electric Fenton reaction process

[0016] Reaction target solution volume: 40ml high-purity water

[0017] Reaction target solution temperature: 25°C

[0018] Solution initial pH: 3.00

[0019] Plate area: 9cm 2

[0020] Electrolyte concentration: 0.02M Na 2 SO 4

[0021] Oxygen flow rate: 30ml / min

[0022] Current intensity: 0.04A, 0.06A, 0.08A, 0.12A

[0023] Reaction time: 10min, 20min, 30min, 40min, 60min

[0024] The hydrogen peroxide generation before and after treatment is shown in Table 1.

[0025] Table 1 Example 1 hydrogen peroxide generation situation

[0026]

[0027] As can be seen from Example 1, as the current intensity increases, the amount of hydrogen peroxide produced also increases, indicating that this method can effectively produce hydrogen peroxide.

Embodiment 2

[0028] Embodiment 2. The removal of algal toxins by different treatment processes

[0029] Reaction target solution volume: 40ml

[0030] Reaction target solution concentration: MCRR 8.81mg / L, MCLR 6.36mg / L

[0031] Reaction target solution temperature: 25°C

[0032] Solution initial pH: 3.00

[0033] Plate area: 9cm 2

[0034] Electrolyte concentration: 0.02M Na 2 SO 4

[0035] Oxygen flow rate: 30ml / min

[0036] Respectively activated carbon fiber (ACF) adsorption (without electricity), Fe-free 2+ Catalytic electro-oxidation and electro-Fenton oxidation (Fe 2+ 1mM) to treat water samples containing algal toxins, the removal of algal toxins before and after treatment is shown in Table 2.

[0037] time

[0038] It can be seen from Example 2 that the algae toxins MC-RR and MC-LR are mainly degraded and removed by the electro-Fenton reaction, and neither adsorpt...

Embodiment 3

[0039] Embodiment 3. The removal of different initial concentrations of algae toxin raw water by electric Fenton

[0040] Reaction target solution volume: 40ml

[0041] Ferrous ion concentration: Fe 2+ 1mM

[0042] Reaction target solution temperature: 25°C

[0043] Solution initial pH: 3.00

[0044] Plate area: 9cm 2

[0045] Electrolyte concentration: 0.02M Na 2 SO 4

[0046] Oxygen flow rate: 30ml / min

[0047] Current intensity: 60mA

[0048] The concentration of algae toxins are a.MCRR 8.81mg / L, MCLR 6.36mg / L b.MCRR4.40mg / L, MCLR 3.18mg / L c.MCRR 2.20mg / L, MCLR 1.59mg / L water samples containing algae toxins The treatment was carried out, and the removal of algae toxins before and after treatment was shown in Table 3.

[0049] time

[0050] It can be seen from Example 3 that the method and device of the present invention have better removal ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com