Core-shell structure fiber functional inorganic biological material as well as preparation method and application thereof

A biomaterial and inorganic technology, applied in medical science, prosthesis, etc., can solve the problems of low pore space, difficult rearrangement, poor regulation ability, etc., to control inflammation, prevent infection, and promote bone regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

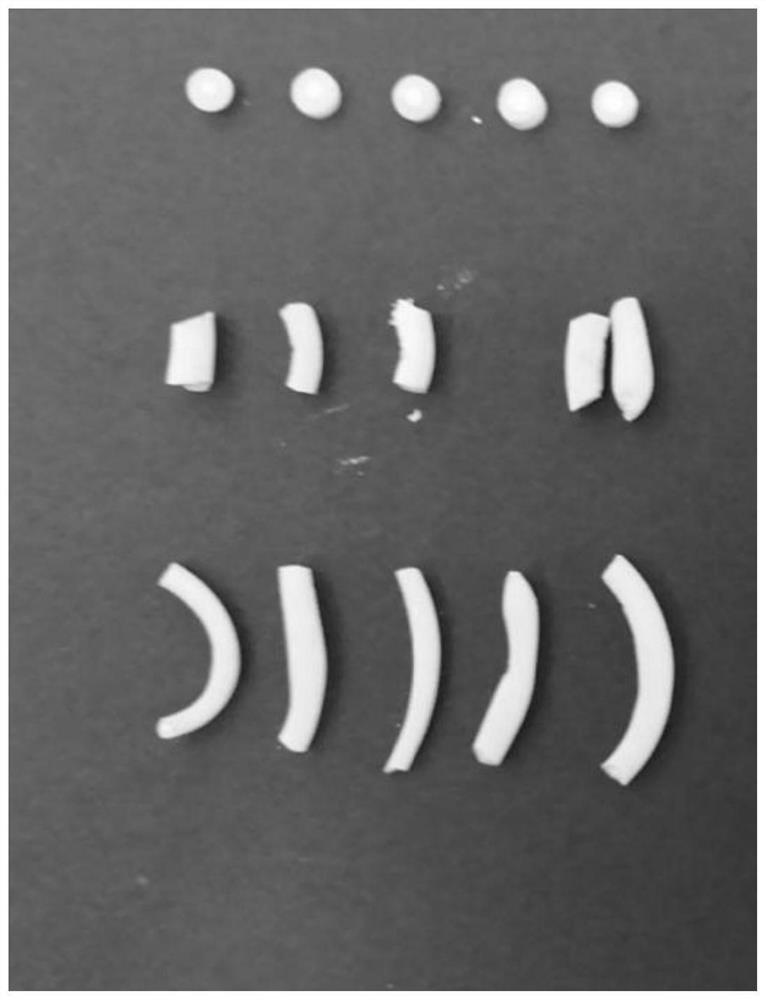

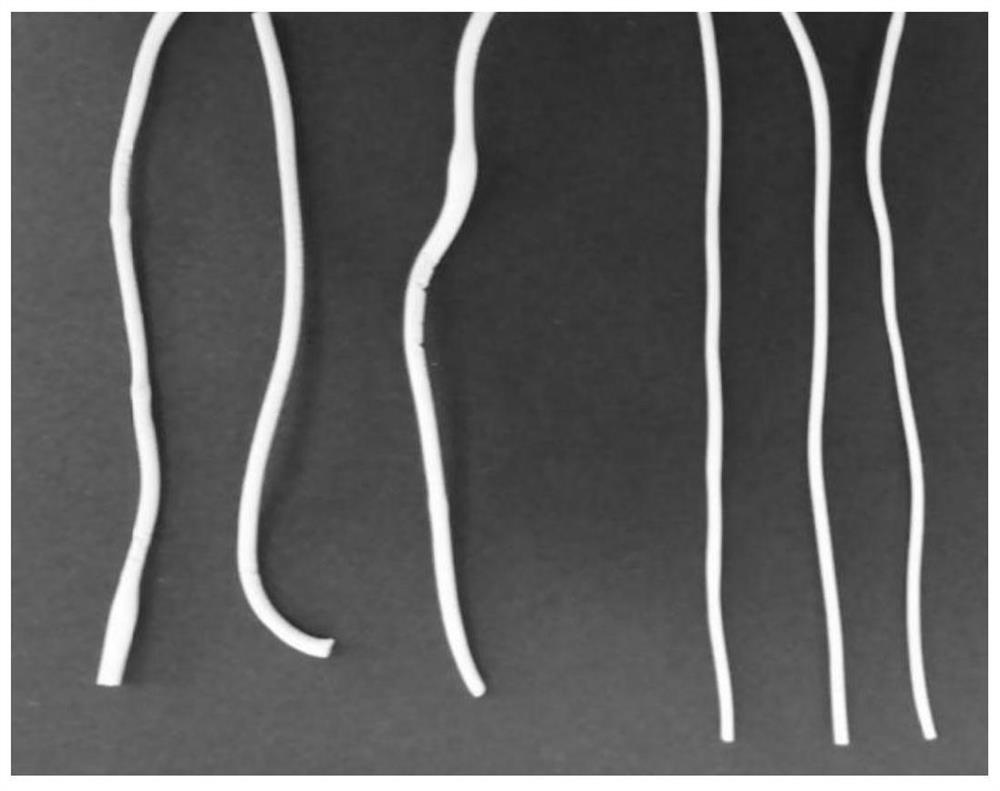

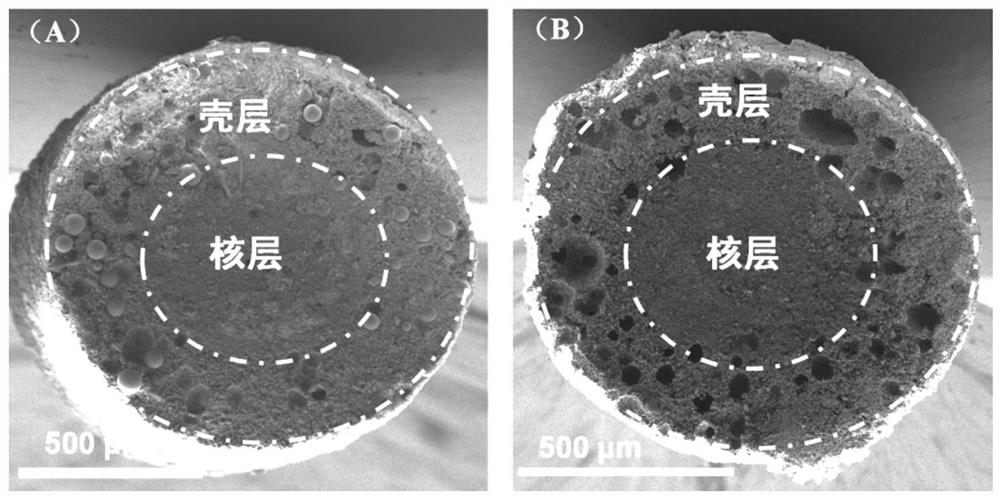

[0139] Example 1 [Porous bioactive ceramic fiber co-doped with core and shell ceramics]: zinc-sodium co-doped β-calcium silicate@silicon-strontium co-doped β-tricalcium phosphate coaxial core-shell Structural bioactive ceramic fibers.

[0140] 1) 2.2% calcium and 4.6% phosphorus are co-doped with strontium and silicon-substituted strontium-phosphorus β-tricalcium phosphate powder, 2.8% zinc and 1.8% sodium are co-doped with β-calcium silicate powder Disperse 45g each into 75mL of 1.5% sodium alginate aqueous solution, stir to form two paste-like slurries, and then add polymethyl methacrylate microspheres 14 with a diameter of 5-8 μm to the two slurries gram, 24 grams of polystyrene microspheres with a diameter of 40-70 μm. Then put them into two material storage containers respectively connected with inner and outer double-layer coaxial tubular nozzles. The slurry is synchronously pushed into the nozzle nozzle of the nozzle to form a core-shell structure paste fiber, and 15%...

Embodiment 2

[0146] Example 2 [Three-layer core-shell structure porous bioactive ceramic composite fiber]: Coaxial core-shell structure composite organism of zinc-doped magnesian feldspar@strontium-doped β-tricalcium phosphate@magnesium-doped β-calcium silicate Active ceramic fibers.

[0147]1) Zinc-doped feldspar with 3.1% calcium replaced by zinc, strontium-doped β-tricalcium phosphate with 4.7% calcium replaced by strontium, and magnesium-doped β-calcium silicate with 8.3% calcium replaced by magnesium Disperse 48g of each powder into 75mL of sodium alginate-carboxymethyl cellulose aqueous solution with a concentration of 1.2% and 0.05% respectively, stir to form three paste-like slurries, and then add 10 15 grams of polystyrene microspheres with a diameter of 12 μm, 18 grams of polystyrene microspheres with a diameter of 5-6 μm and 12 grams of polystyrene microspheres with a diameter of 50-65 μm. Then put them into three material storage containers connected with the inner, middle and...

Embodiment 3

[0150] Example 3 [core-shell structure composite bioactive ceramic fiber with parallel core layers]: strontium-zinc co-doped feldspar and phosphorous-doped womanite are parallel core layers, and silicon-doped α-tricalcium phosphate Bioactive ceramic fiber composite material for the shell layer.

[0151] 1) 3.4% and 2.8% calcium were replaced by strontium, zinc substituted strontium / zinc co-doped fennelite, 8% silicon was replaced by phosphorus, phosphorus-doped wollastonite, 6% phosphorus was replaced by silicon Disperse 35g of α-tricalcium phosphate powder into 75mL of sodium alginate aqueous solution with a concentration of 2.4%, stir to form three kinds of paste-like slurries, and then add polyphenylene oxide with a diameter of 5μm to the three kinds of slurries respectively. Ethylene Microspheres 14g. Then put it into three material storage containers respectively connected with the parallel dual-core layer nozzle and a shell layer nozzle. The inner diameters of the nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com