Patents

Literature

196 results about "Biomaterial preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

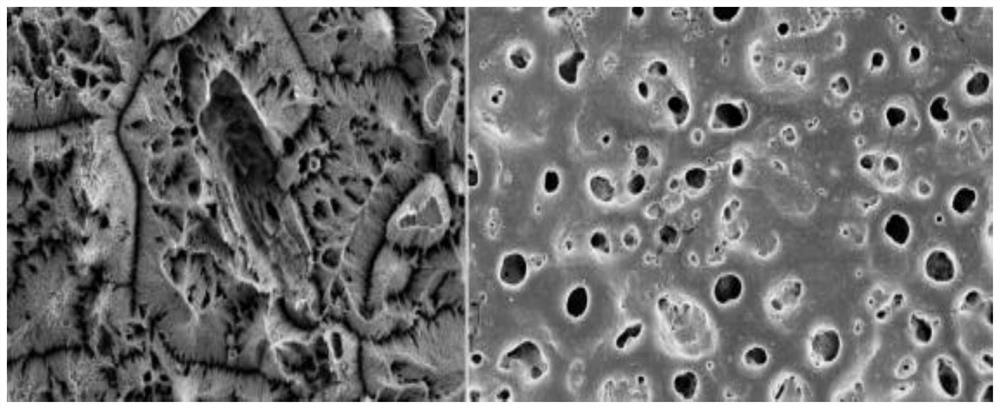

Biomaterial Preparation. Elasthane 80A, a polyether urethane (PEU), was synthesized by Polymer Technology Group (Berkeley, CA, USA) and extruded by Medtronic (Minneapolis, MN, USA).

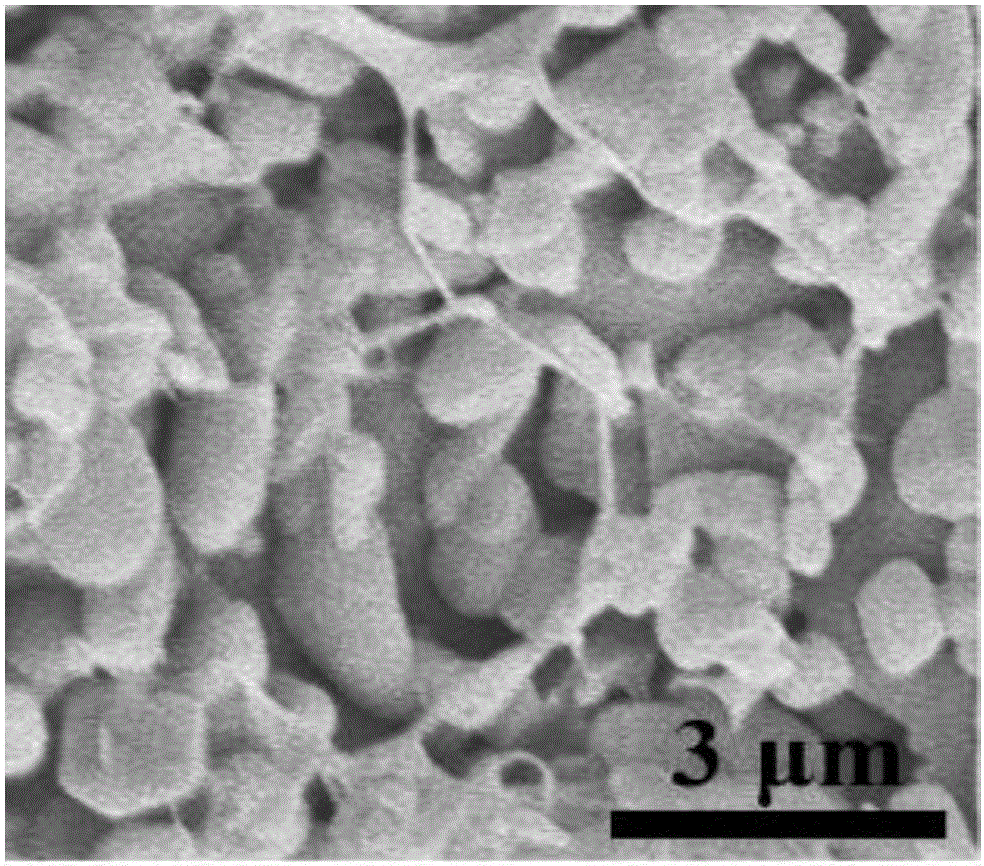

Preparation method of self-adhesion electroconductive hydrogel

The invention discloses a preparation method of self-adhesion electroconductive hydrogel and belongs to the technical field of biomaterial preparation. The preparation method includes following steps: introducing double bonds on biomacromolecules through methyl acrylic anhydridization to obtain double-bond biomacromolecules; preparing a polydopamine-functionalized electroconductive nano material, and polymerizing the double-bond biomacromolecules and the polydopamine-functionalized electroconductive nano material through photo-initiated free radicals to obtain the self-adhesive electroconductive hydrogel. With reference to adhesiveness of mussel-imitated materials, phenolic hydroxyl functional group with adhesiveness is introduced, and regulation of self-adhesion performance of the hydrogel is realized by changing content of the phenolic hydroxyl functional group. In addition, the self-adhesion electroconductive hydrogel prepared by the method has high electroconductivity, mechanical performance and biocompatibility, and application range of the hydrogel is widened. The preparation method has the advantages of being simple and easy to implement, controllable in polymerization process, high in polymerization speed and low in energy consumption.

Owner:SOUTHWEST JIAOTONG UNIV

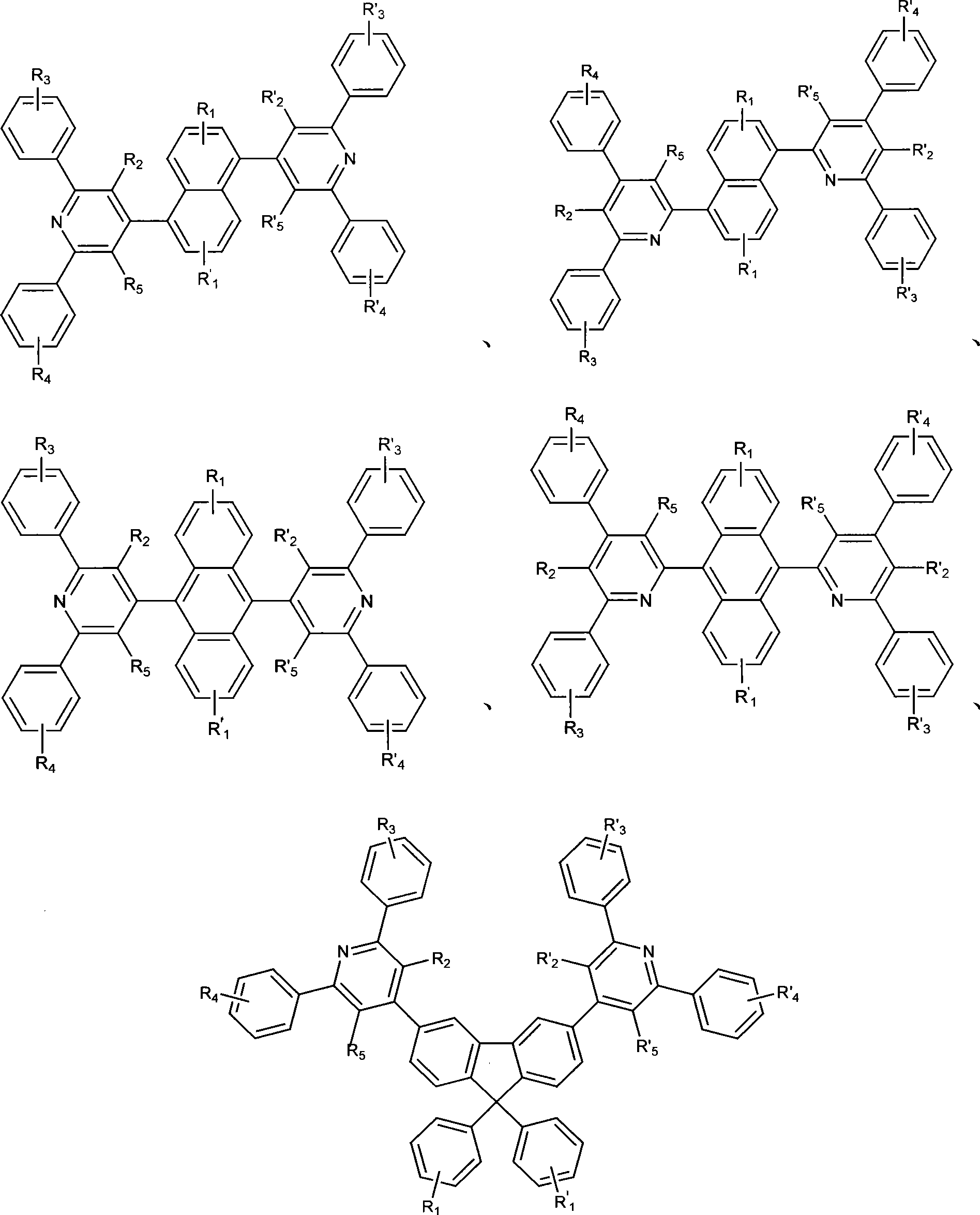

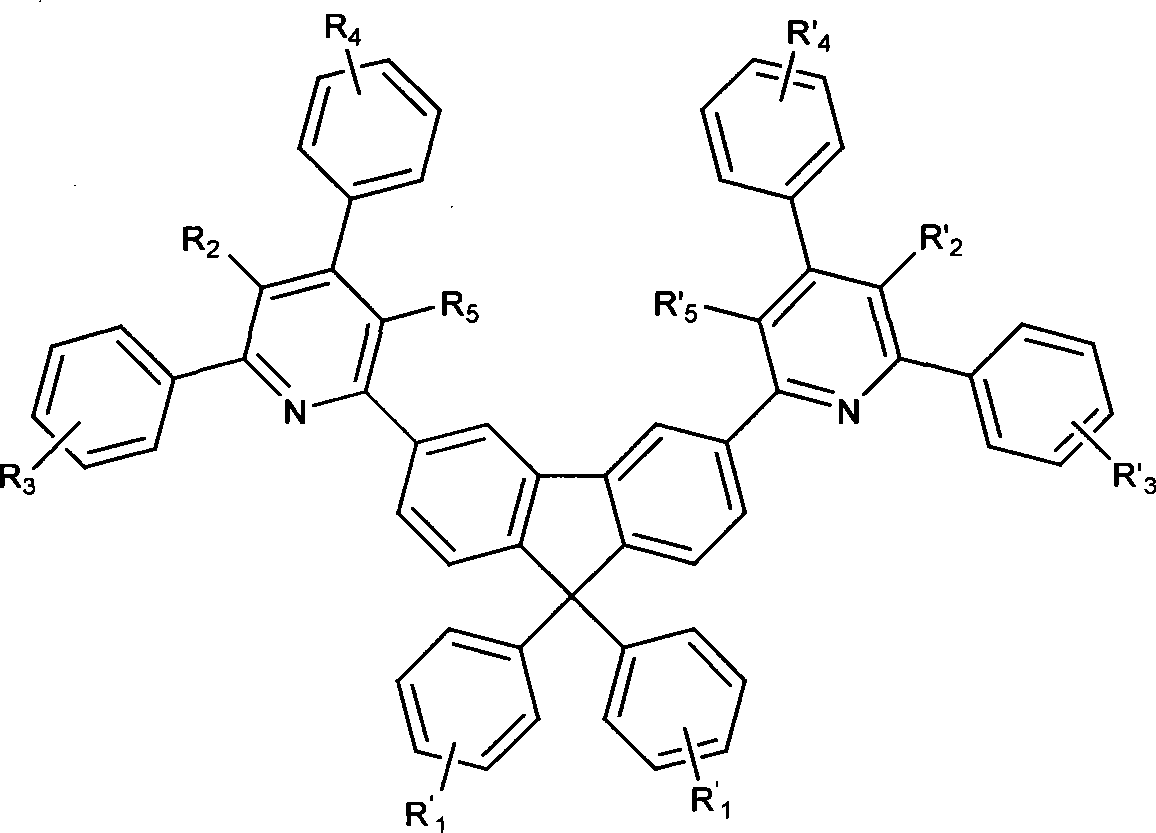

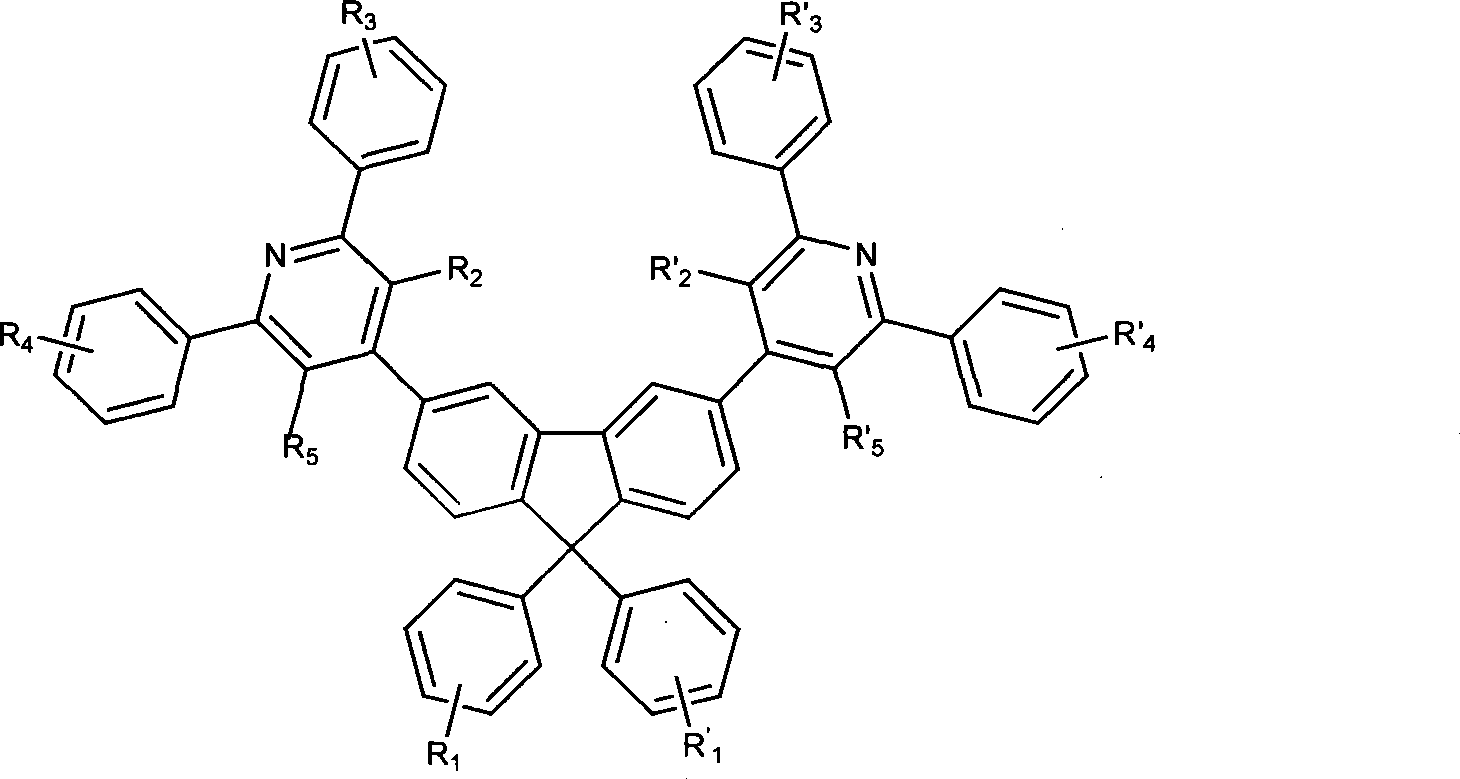

Electroluminescent organic material, synthetic method and use thereof

InactiveCN101412907AHigh IP/EA valueHigh quantum yieldElectroluminescent light sourcesSolid-state devicesArylSynthesis methods

The invention belongs to the field of organic electroluminescent material, and in particular relates to polyaryl substituted pyridine derivatives and a synthetic method thereof, as well as application to preparing organic electroluminescent devices by using materials of the polyaryl substituted pyridine derivatives. Through molecular design, the synthetic method introduces large substituting groups which have rigid structures to ensure that the large substituting groups are not easy to form a group excited compound, inhibits the crystallization processes of the large substituting groups, improves the film forming properties of the large substituting groups, and increases charge transfer performances of the large substituting groups; at the same time, destroy of molecular co-planarity makes the large substituting groups emit peak blue shift, so as to achieve the aim of improving the properties of the devices. The polyaryl substituted pyridine derivatives comprise a structural formula as above.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing aquogel matrix for ultraviolet light three-dimensional (3D) printing

InactiveCN104861216AOvercome polymerization inhibitionImprove printing efficiencyCell adhesionPolyvinyl alcohol

The invention relates to a method for preparing an aquogel matrix, in particular to a method for preparing the aquogel matrix for ultraviolet light three-dimensional (3D) printing and belongs to the technical field of preparation of biological materials. An alkenyl group is ingrafted on a chitosan molecular chain, a sulfydryl group is ingrafted on polyvinyl alcohol, and mixing is performed to obtain the aquogel matrix for ultraviolet light 3D printing. According to the aquogel matrix, sulfydryl-alkene 'click' reaction characteristic is fully utilized, gel forming is rapidly achieved under ultraviolet irradiation, inhibition of oxygen in air or a system can be fully overcome, 3D printing efficiency is greatly increased, cytocompatibility of the aquogel matrix is good, enough supporting environment is provided for cell growth, and cell adhesion, growth and proliferation can be facilitated. The preparation method is simple and low in costs, and industrial production is easy.

Owner:WUHAN TEXTILE UNIV

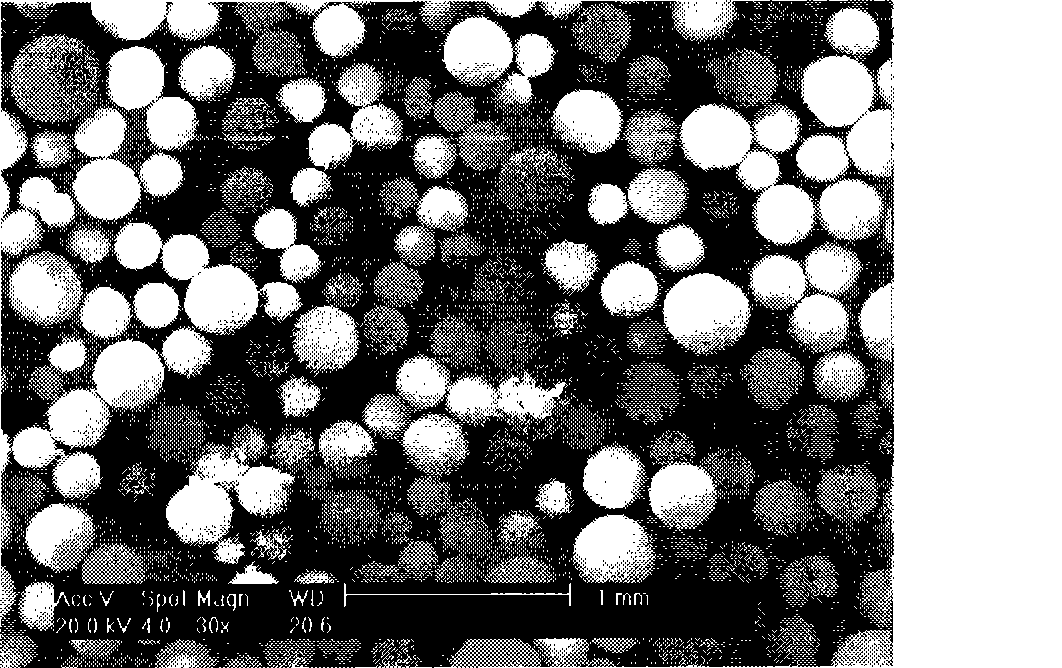

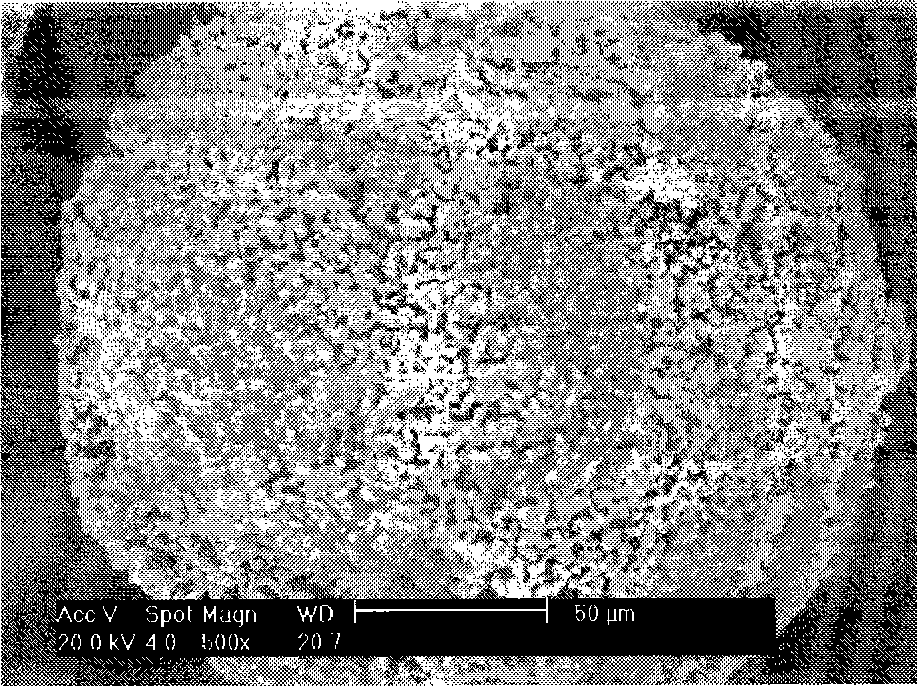

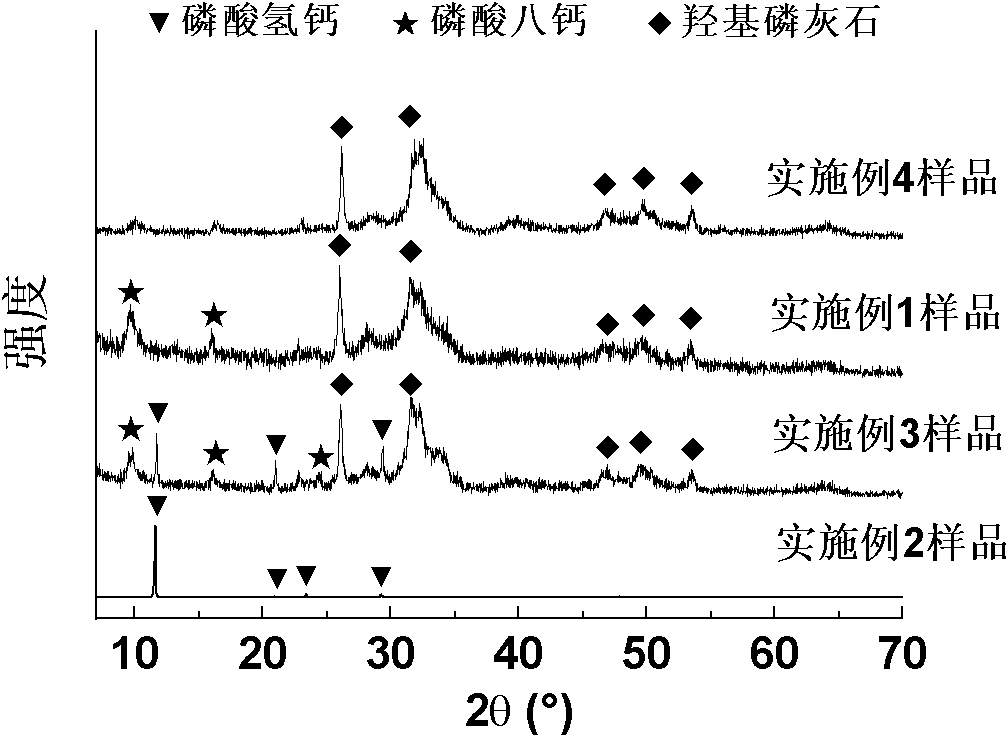

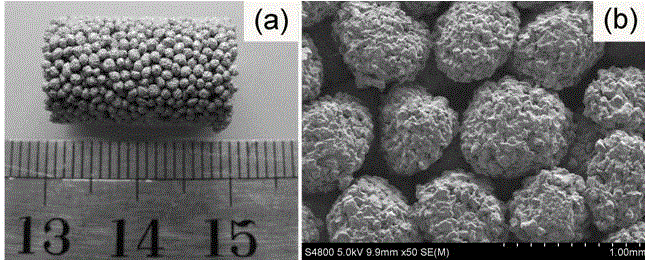

Preparation method of drug-carrying hydroxylapatite microspheres and bone cement composite porous microspheres

InactiveCN101361715AThe release rate is easy to controlLarge and adjustable drug loadingInorganic non-active ingredientsGranular deliveryApatiteHydroxylapatite

The invention discloses a preparation method of porous microspheres composite with hydroxyapatite microspheres being capable of carrying drugs and bone cement, which belongs to the technical field of biological material preparation. The method comprises the following steps: the preparation of nano hydroxyapatite powders; the preparation of Alpha- tricalcium phosphate powders; the preparation of the hydroxyapatite microspheres; and the preparation of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement. The method has the advantages that: the porosity of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement, and the size of the microspheres can be easily controlled; the composite of the drugs can be carried out by the preparation process of the bone cement stuff, the drug-carrying rate is large and controllable; and the composite porous microspheres can be served as drug carriers or stents with integration of bone restoration and cure.

Owner:TIANJIN UNIV

Degradable material capable of guiding the regeneration and renovation process of hard tissue and its preparation

InactiveCN1546181APromote repairControllable degradation rateSurgeryProsthesisSurgical operationBiological materials

The invention discloses a degradable material for conducting hard tissue regeneration and renovation, and its preparation method which comprises, using degradable biomaterial collagen, chitosan or hydroxyl chitosan, tertiary calcium phosphate or hydroxyapatite as principal raw material, preparing acid solution and suspending liquid, mixing to prepare hard tissue filler, wherein the prepared biological material has good compatibility with the wound tissue.

Owner:TSINGHUA UNIV

Fibroin medical biological adhesive and preparation method thereof

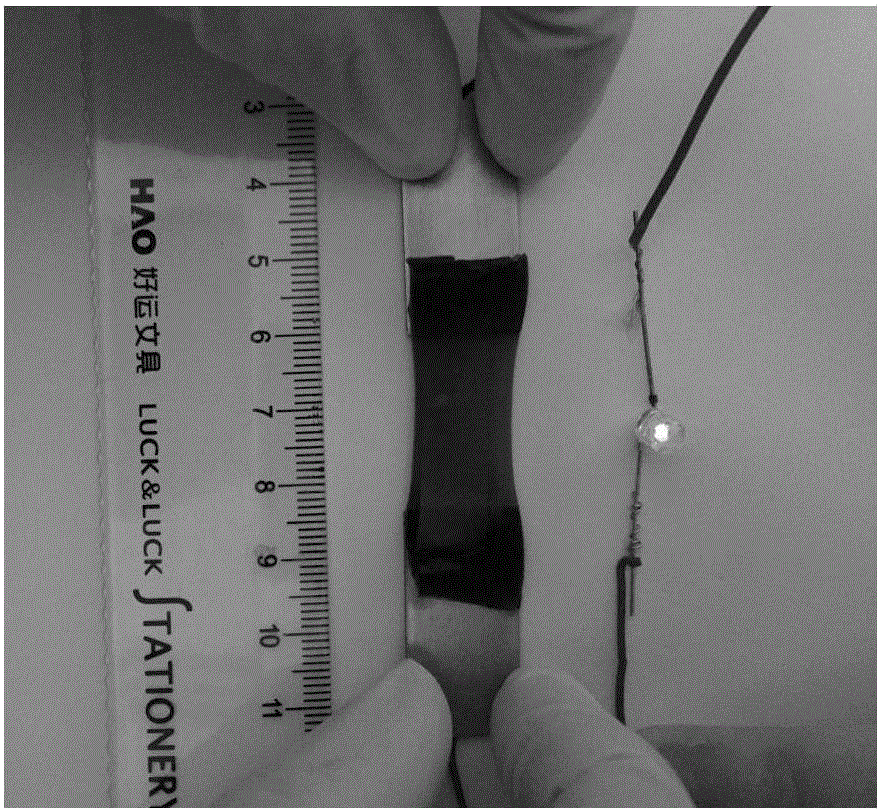

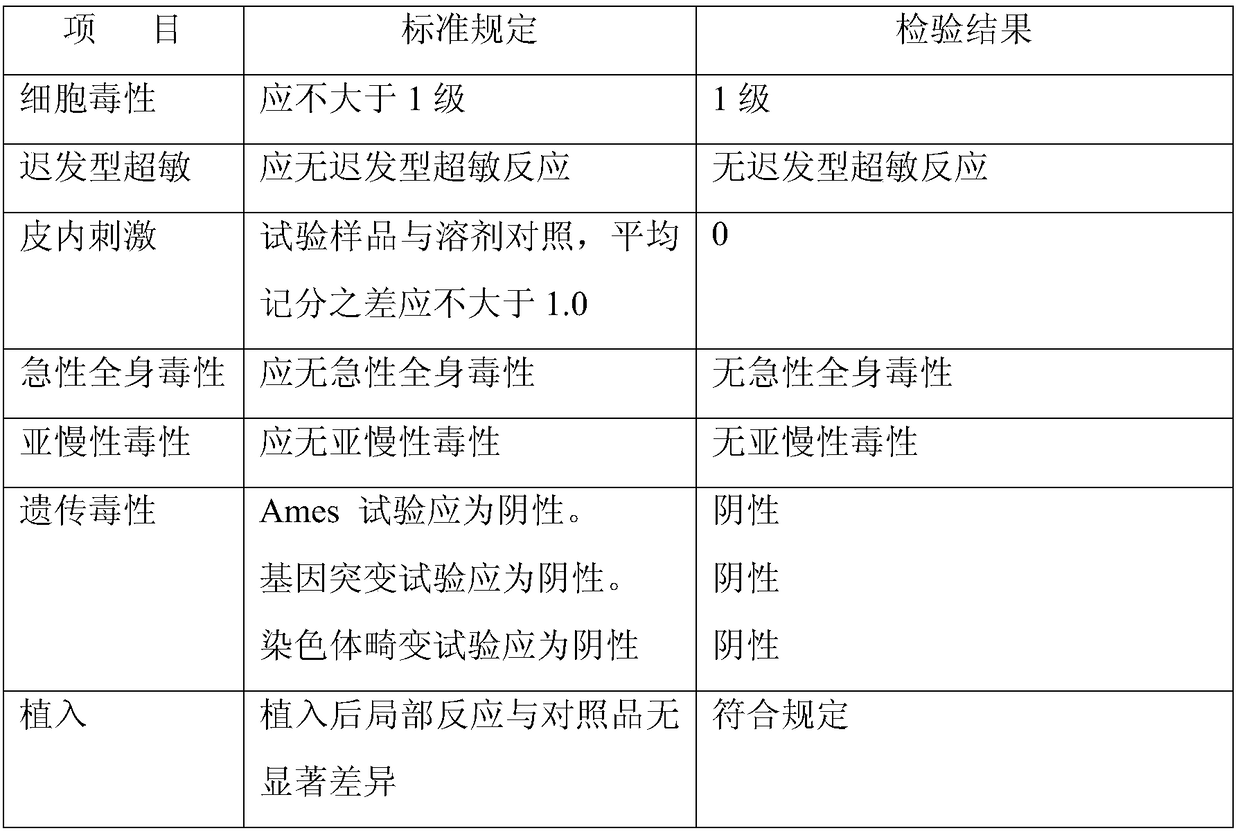

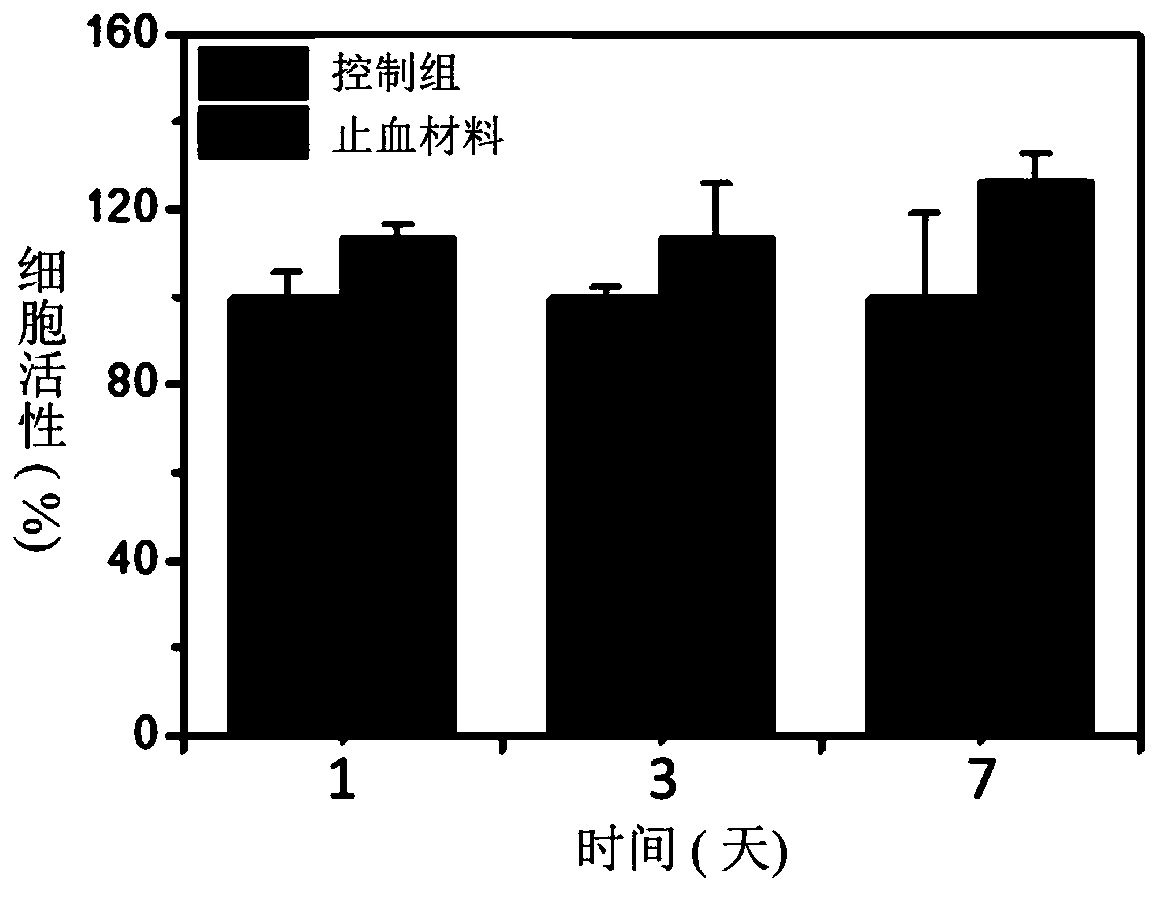

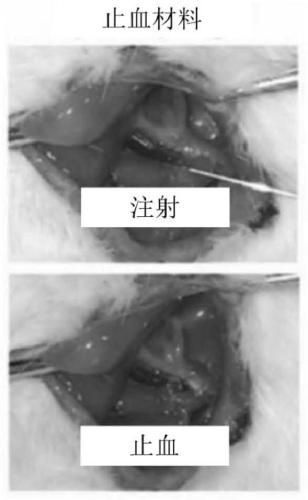

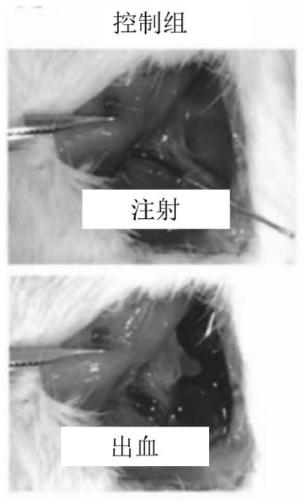

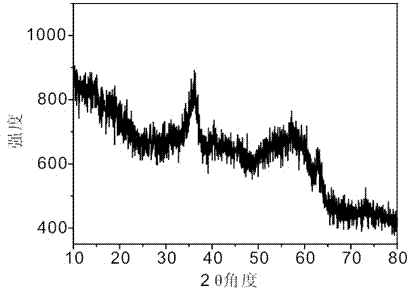

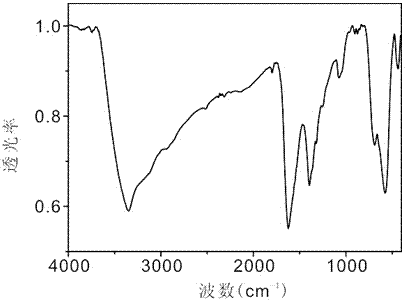

ActiveCN108744023AGood biocompatibilityFast bondingSurgical adhesivesPharmaceutical delivery mechanismBioadhesiveBiocompatibility Testing

The invention discloses a fibroin medical biological adhesive and a preparation method thereof, and belongs to the field of biomaterial preparation and biomedical application. The adhesive is preparedby uniformly mixing a fibroin solution and a polyphenolic polymer solution at room temperature. The fibroin biological adhesive has the advantages of high adhesion strength, high adhesion speed, safety, no toxicity, good biocompatibility and low price in a humid environment. The adhesive is simple to operate and easy to grasp, and suture removal and other secondary operations are not required after an operation to relieve the pain of a patient. The small or even scar-free wound surfaces have a cosmetic effect. The adhesive can be used on almost all wound surfaces, has the effects of bonding tissues, covering the wound surfaces, filling gaps and voids, stopping bleeding, inhibiting bacteria and the like, can be used as a hemostatic adhesive material for tissues such as skins, organs, bloodvessels, nerves, muscles, mucous membranes, bones, joints and eyes, and has extensive clinical application prospects.

Owner:FUZHOU UNIV

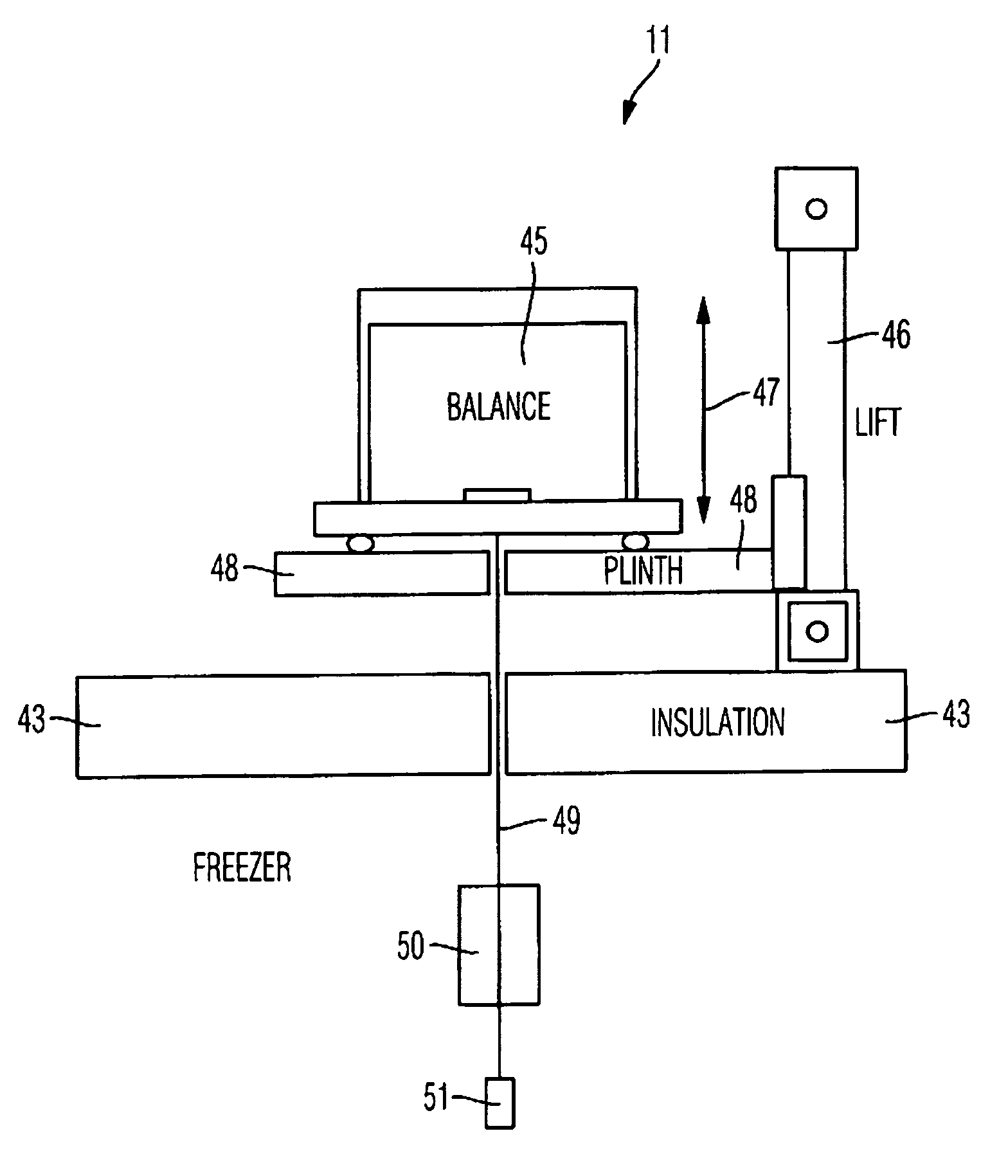

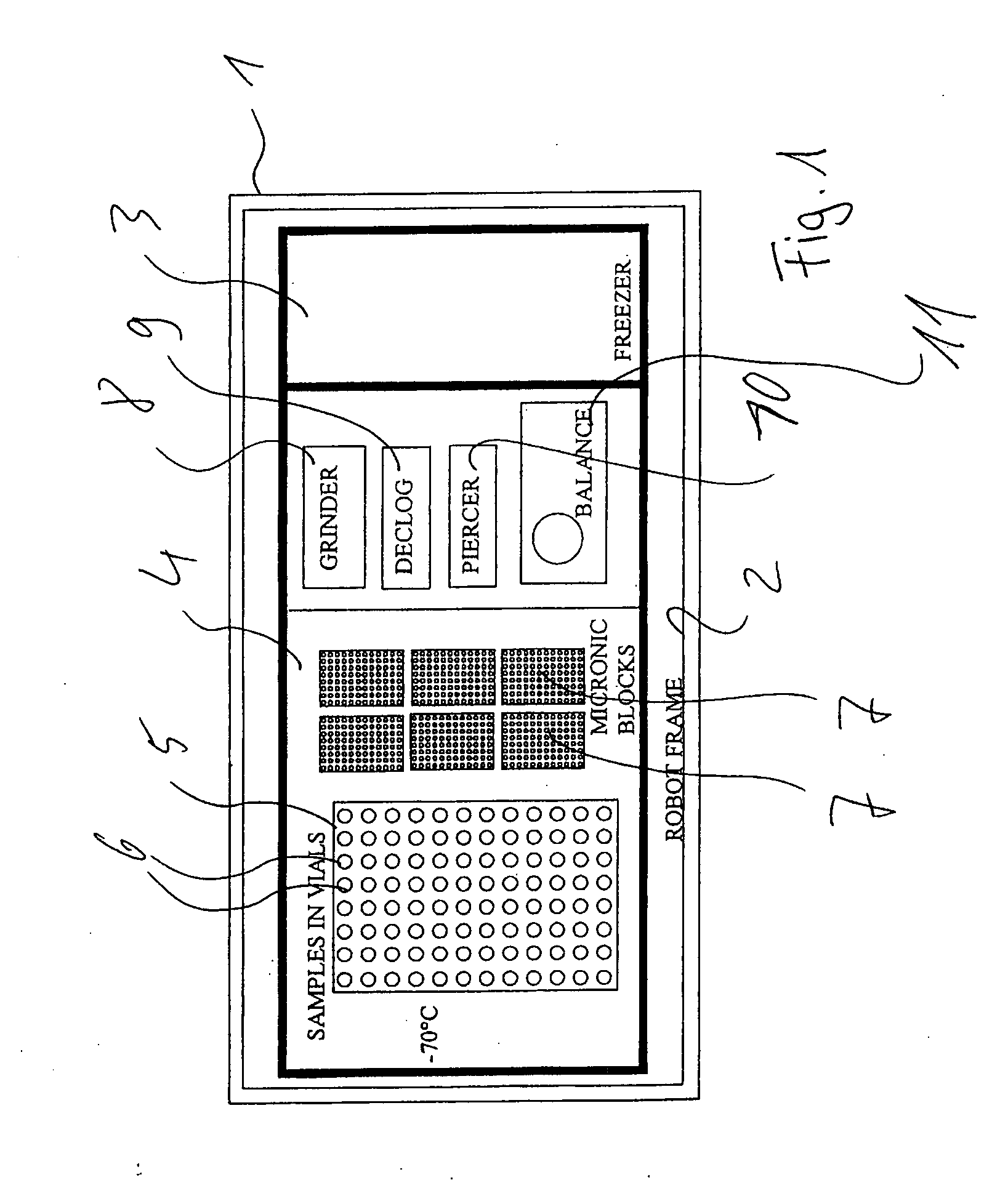

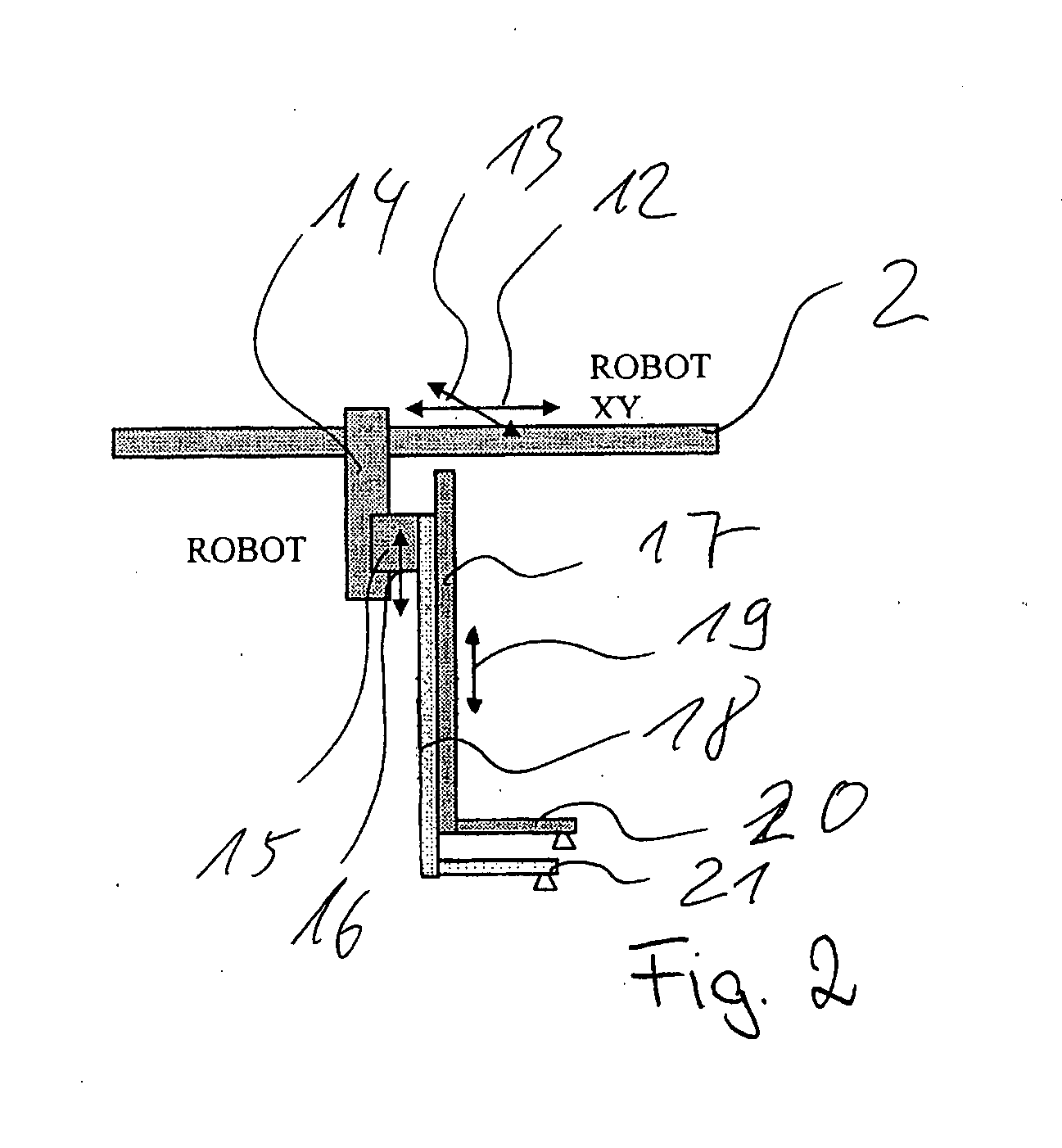

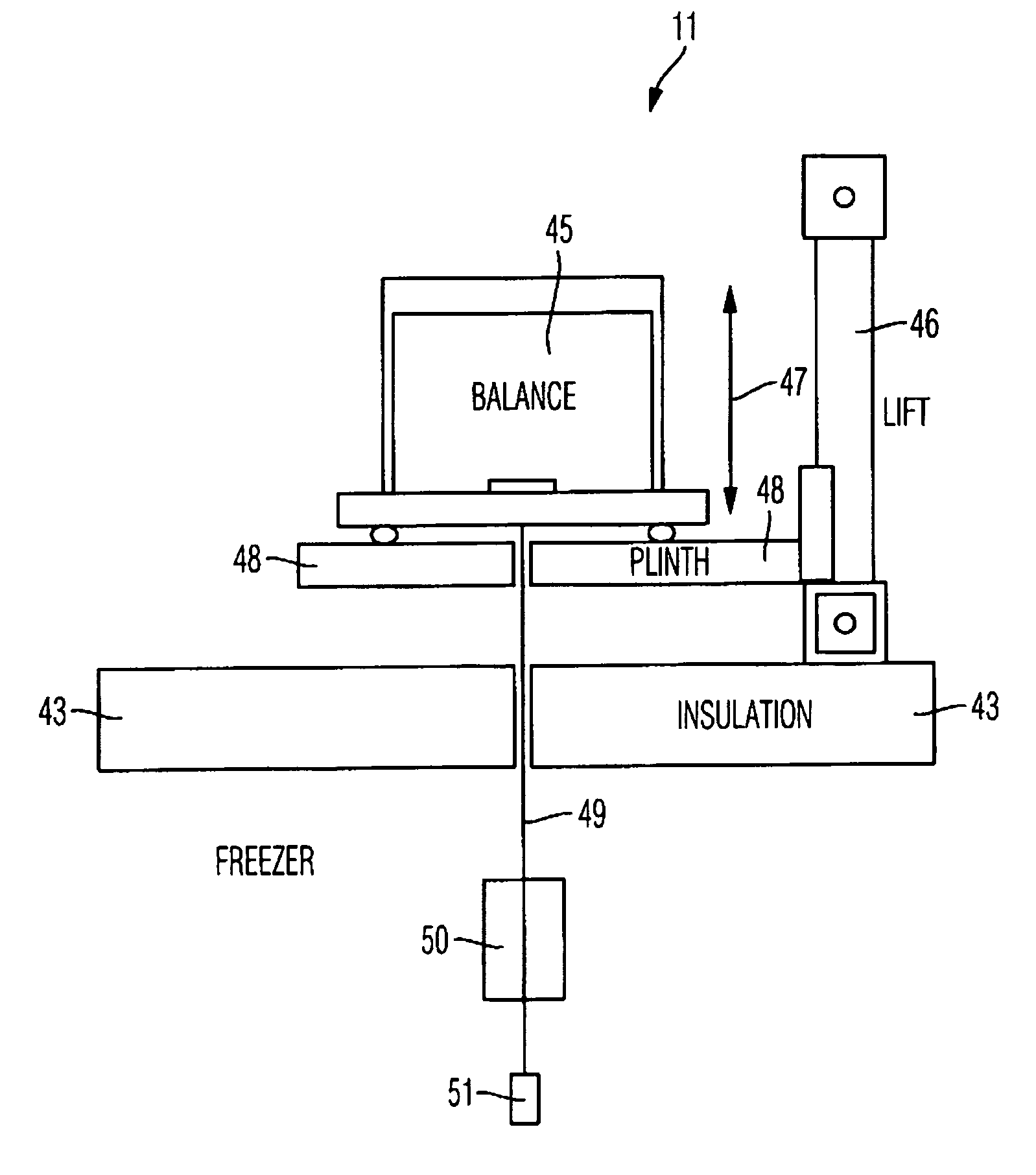

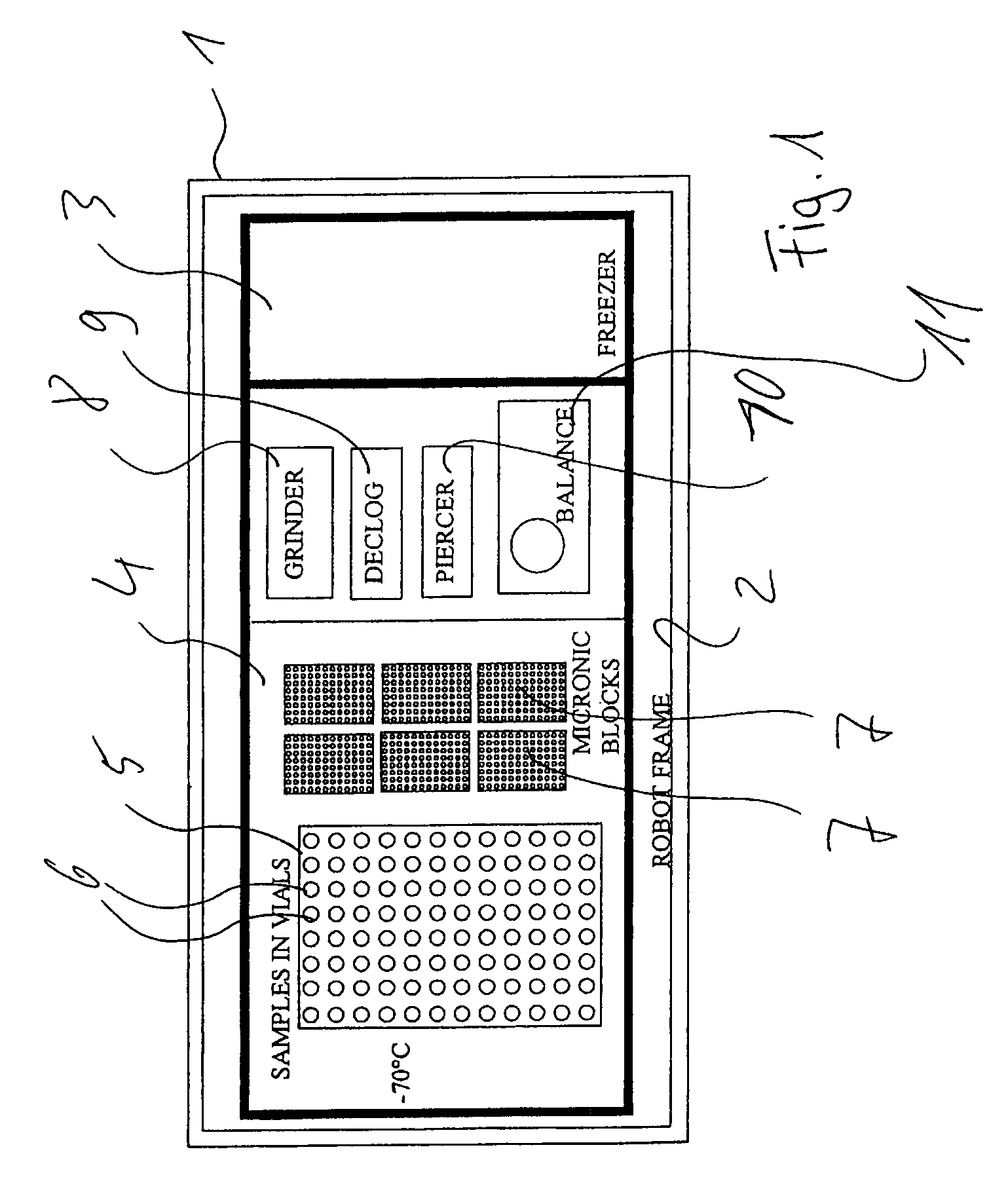

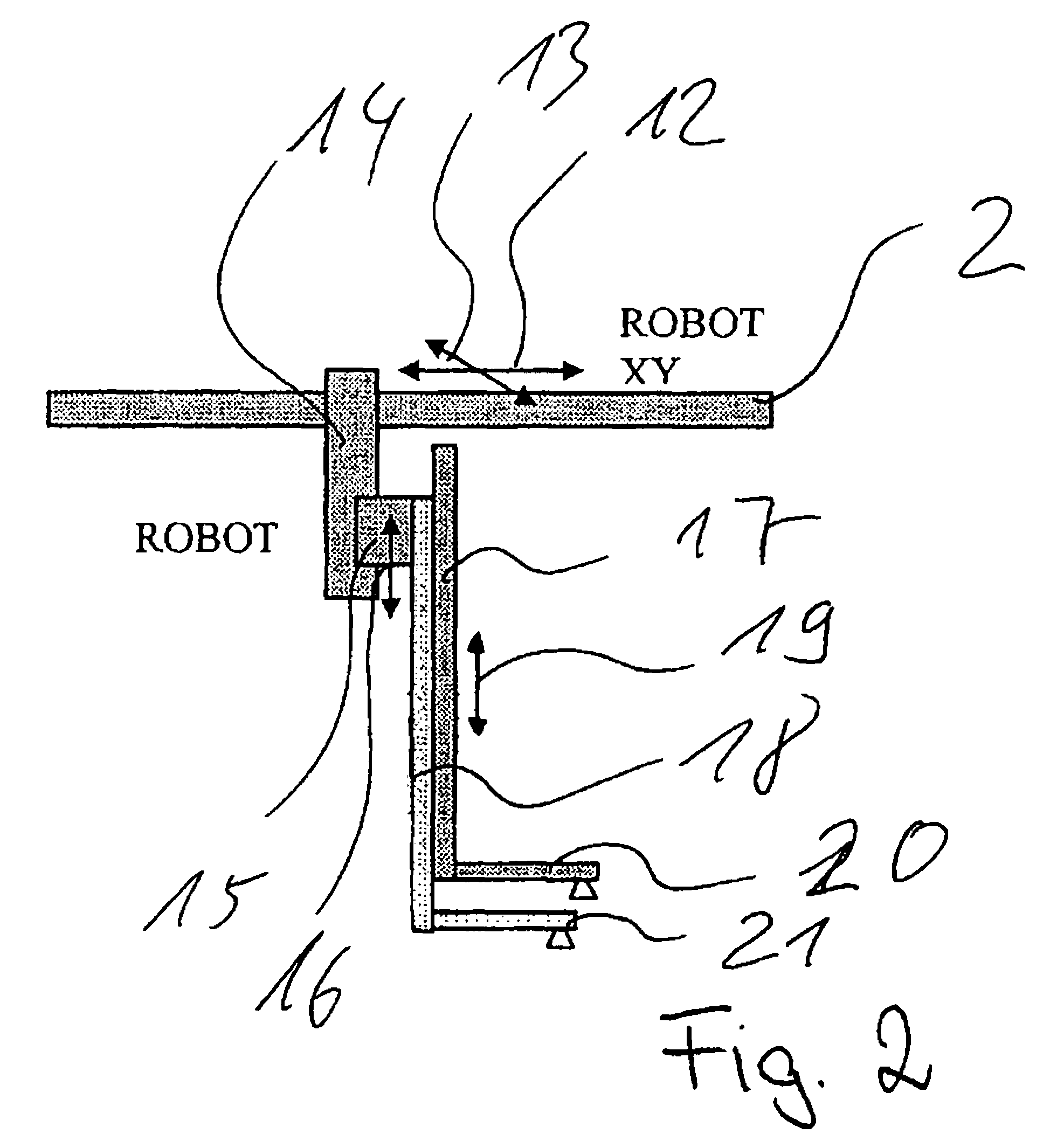

System and method for producing weighed portions of powder from at least one biological material at cryotemperatures

InactiveUS20090101738A1Reduce frostingIncrease productionPreparing sample for investigationGrain millingMetallurgyBiological materials

A system and a method for producing a quantified defined portions of powder from at least one biological material at cryotemperature is shown, comprising means for grinding the biological material deposited in at least one first vessel to the powder; means for loosening the powder resulting from grinding the biological material in the first vessel; means for positioning at least one first opening in the first vessel, and means for transferring the quantified defined portions of powder in a plurality of second vessels by using the first opening as a transfer way.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

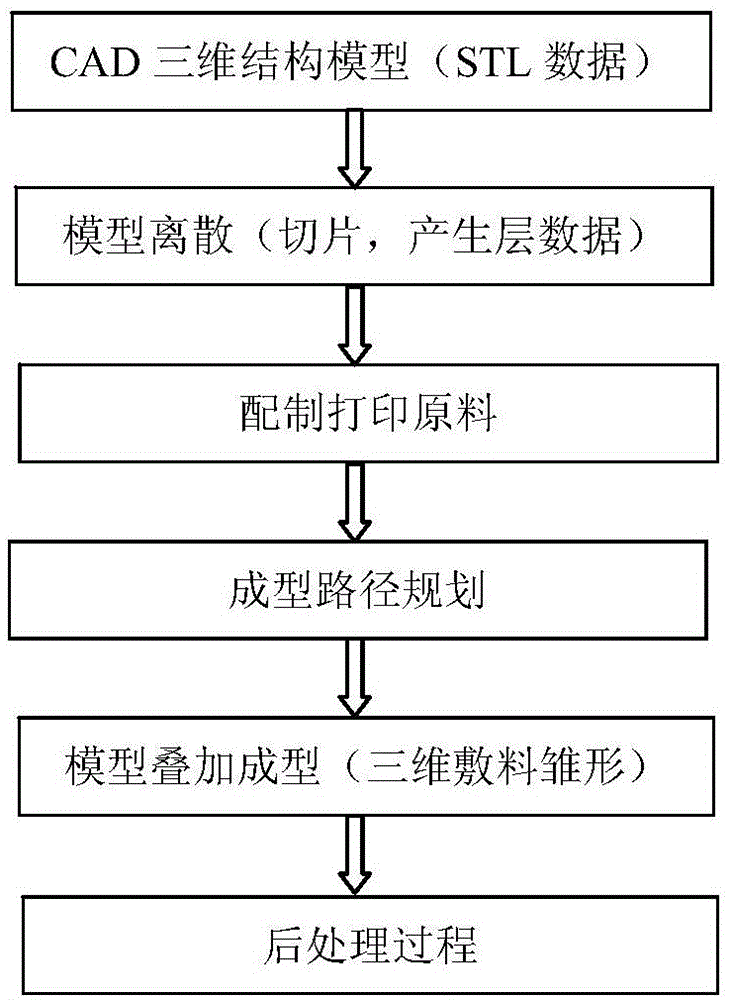

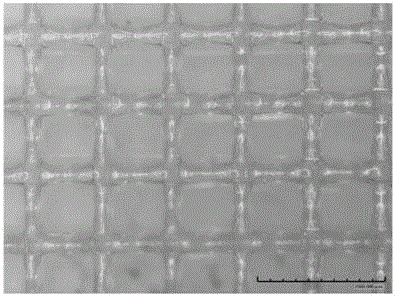

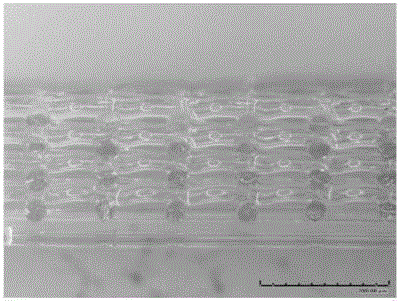

3D bio-printing medical dressing and preparation method thereof

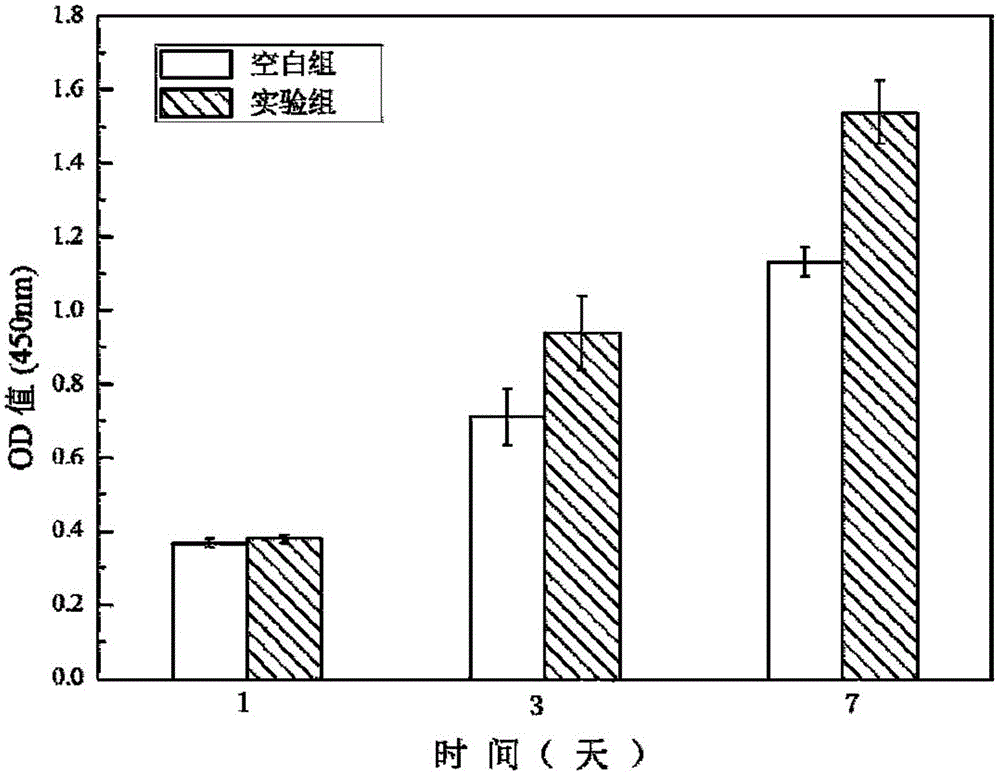

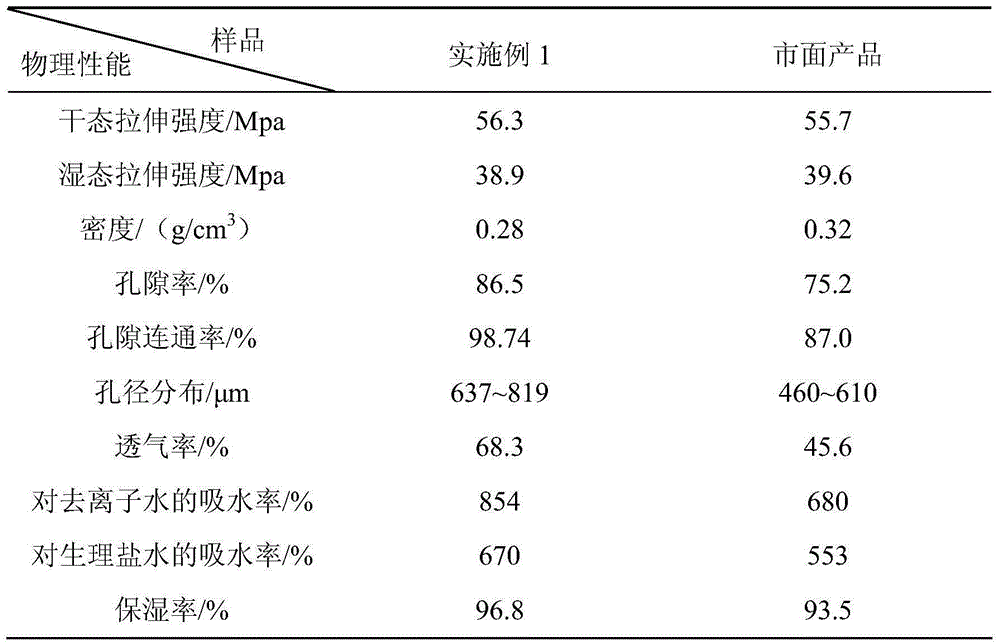

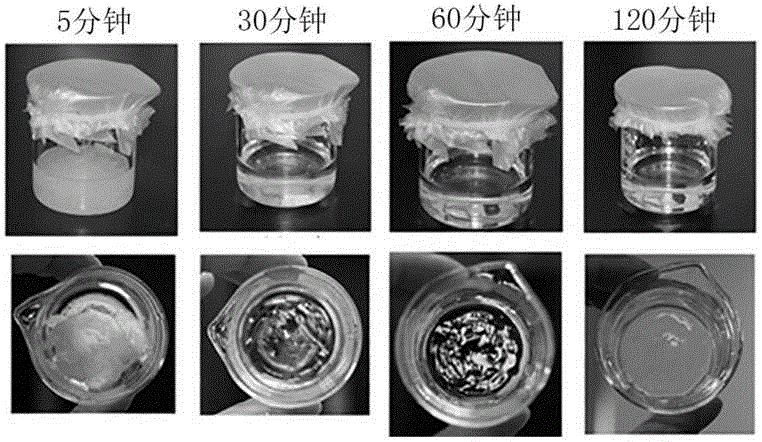

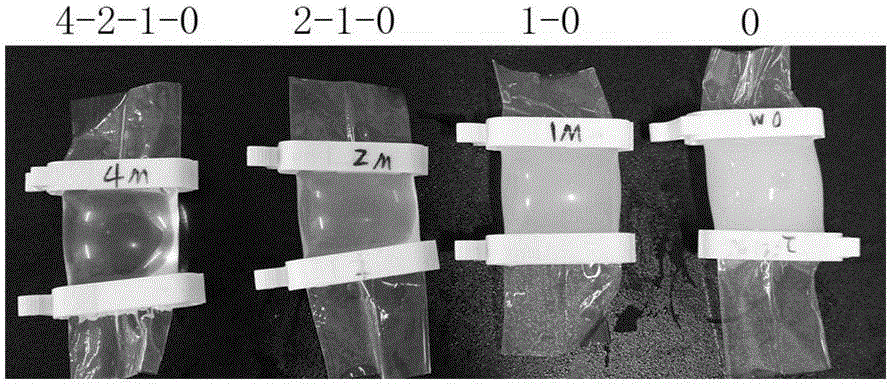

InactiveCN105031713ASimple manufacturing processEasy to operateAdditive manufacturing apparatusAbsorbent padsCell freeSide effect

The invention discloses a 3D bio-printing medical dressing and a preparation method thereof. The medical dressing takes cell-free collagen as a main component and is prepared by a rapid prototyping technology. According to the invention, the medical dressing prepared from a bio-material containing cell-free collagen has the advantages of good biocompatibility, no toxic or side effect and no immunological rejection; meanwhile, by using the rapid prototyping technology for preparing the dressing with a 3D structure, the preparation process is convenient and fast, the operation steps are simple, the geometric shape, pore diameter, porosity and pore distribution of the dressing can be accurately controlled according to wound sizes of different patients and the characteristics of the material, and thus personalized medical dressings with good air permeability and hydroscopic property for patients can be prepared.

Owner:SOUTH CHINA UNIV OF TECH

Fully biodegradable plastic resin and its film product production method

The present invention discloses a completely-bio-degradable plastic resin and production method of its film product. Its main raw material includes corn starch, cassawa starch, stearic acid, talcum powder, glycerine, sorbitol, ethylene-acrylic acid copolymer and full biological material. Its preparation method includes the following steps: mixing above-mentioned all the raw materials, using improved twin screw extruder to make extrusion and granulating.

Owner:张晓程

Preparation and identification method of domestic silkworm silk fibroin solution

ActiveCN104672316AAvoid hydrolysisHigh molecular weightPeptide preparation methodsBiological testingSILK SERICINChloride

The invention relates to the technical field of biomedicines, and in particular relates to a preparation and identification method of a domestic silkworm silk fibroin solution. The preparation method of the domestic silkworm silk fibroin solution sequentially comprises the following steps: (1) degumming, namely degumming domestic silkworm silks to remove silk sericin on the outer layer to obtain degummed silks; (2) dissolving the silks, namely dissolving the degummed silks by using a ternary solution containing calcium chloride to obtain a fibroin solution; (3) performing renaturation, namely sequentially performing dialysis treatment on the fibroin solution according to a concentration gradient from high to low by using a protein denaturant solution, and then performing water dialysis treatment to obtain a silk fibroin solution; and (4) storing, namely storing the silk fibroin solution. The invention also provides an identification method of the domestic silkworm silk fibroin solution. The method can be used for identifying the quality of the silk fibroin solution. The preparation method of the domestic silkworm silk fibroin solution disclosed by the invention is relatively high in economical performance, ensures that the molecular weight of the domestic silkworm silk fibroin solution is close to that of natural fibroin molecules, and is beneficial to the preparation of subsequent silk fibroin based biomaterials.

Owner:SUZHOU SIMEITE BIOTECH CO LTD +1

Preparation method of hyaluronic acid tissue adhesive

ActiveCN107158453AIncrease contentHigh bonding strengthSurgical adhesivesPharmaceutical delivery mechanismTissue fluidUltraviolet lights

The present invention relates to a preparation method of a tissue adhesive, particularly to a preparation method of a hyaluronic acid tissue adhesive, and belongs to the technical field of biological material preparation. According to the preparation method, by modifying the sodium hyaluronate molecule with the maleoyl, the aldehyde group and the dopamine, the grafted dopamine content can be substantially improved, the adhesion effect of the high content dopamine can be completely provided, and the adhesion strength can be synergistically enhanced through the interaction between the residual aldehyde group and the amino in the tissue; with the preparation method, the low-content carbon-carbon double bond substitution can be achieved, and the problems of incomplete adhesion surface sealing and tissue fluid seepage caused by the shrinkage during the subsequent curing of the obtained tissue adhesive can be avoided; and the prepared tissue adhesive has advantages of rapid gelatin under the irradiation of ultraviolet light, safe gelatin, good biocompatibility, high bonding strength, and complete degradation and absorption.

Owner:WUHAN TEXTILE UNIV

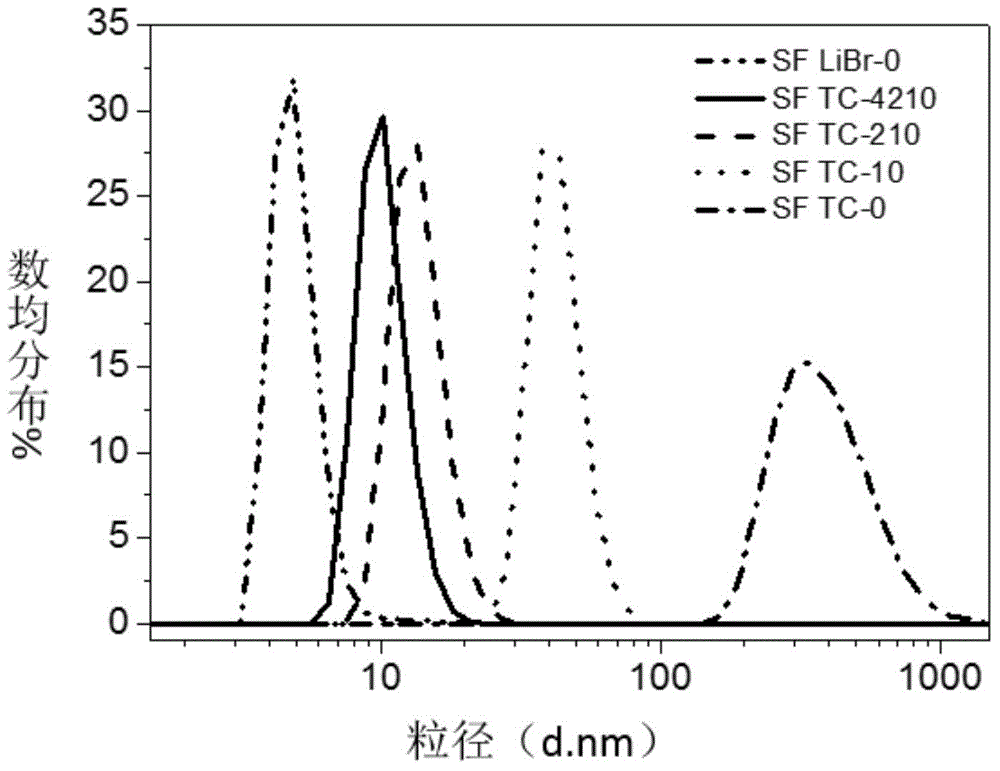

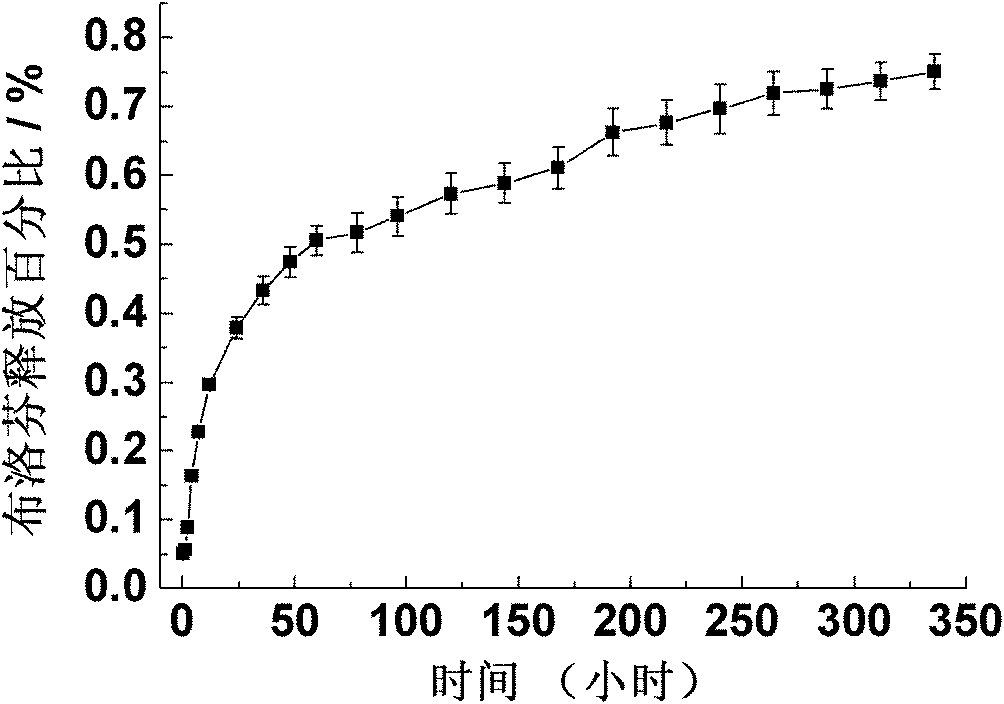

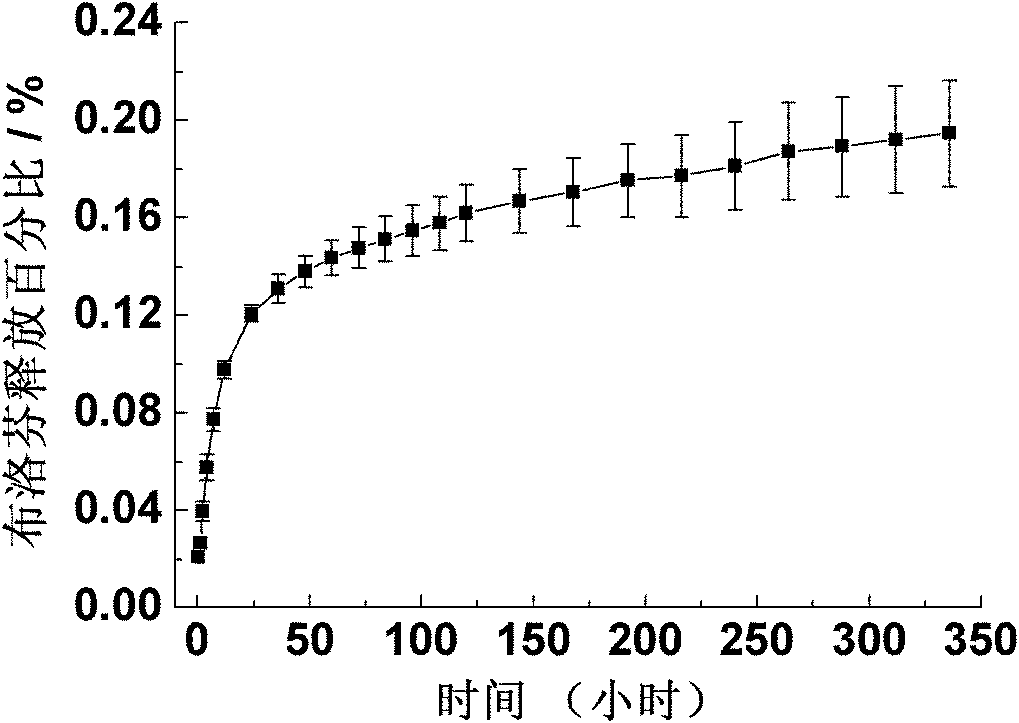

Preparation method of calcium phosphate nano medicament-carrying systems

ActiveCN101979091ASimple processCraft shortInorganic non-active ingredientsProsthesisWater insolublePhosphate

The invention relates to a preparation method of calcium phosphate nano medicament-carrying systems and belongs to the field of biomaterial material preparation and medicament sustained release. By the method, a calcium phosphate nano carrier is prepared in a mixed solvent and is synchronously loaded with water-insoluble medicaments. The method comprises the following steps of: dissolving soluble calcium salt and the water-insoluble medicaments into an organic solvent; adding aqueous solution of soluble phosphate; and synthesizing the calcium phosphate nano carrier, and synchronously carrying the medicaments at the same time. The carrying capacity of the medicaments can be regulated by changing pH value and the concentration of reactants. The prepared series of calcium phosphate nano medicament-carrying systems have different medicament carrying capacities and medicament sustained-release effects. The invention has the advantages that: the preparation method has a simple and fast process and low cost, is environmental friendly and easy to industrialize, and the like.

Owner:江苏先进无机材料研究院

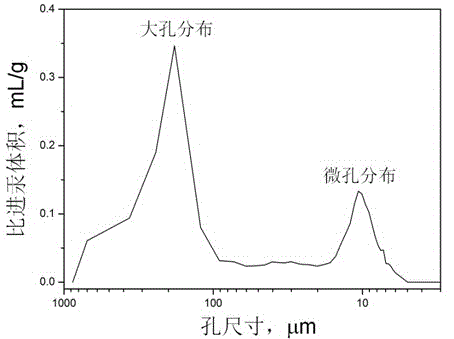

Injectable porous bone cement and preparation method thereof

The invention relates to injectable porous bone cement and a preparation method thereof, and belongs to the field of preparation of a biomedical material. The bone cement takes carbonate as a solid foaming agent, sulfate as a curing accelerator, and chitosan and hydroxypropyl methyl cellulose as bi-component cross-linking agents; during the preparation of injectable porous bone cement, the coagulation time is 5-25min; the bone cement is not defeated and dispersed after being solidified for 20min to 2h; a cured product is provided with 100-1000-microns communicated holes; and the porosity is 1-70%, and the compressive strength is 0.5-40MPa. The preparation method provided by the invention is simple in process, and easy to implement; and the prepared injectable porous bone cement is excellent in overall performance, and can be produced on a large scale.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

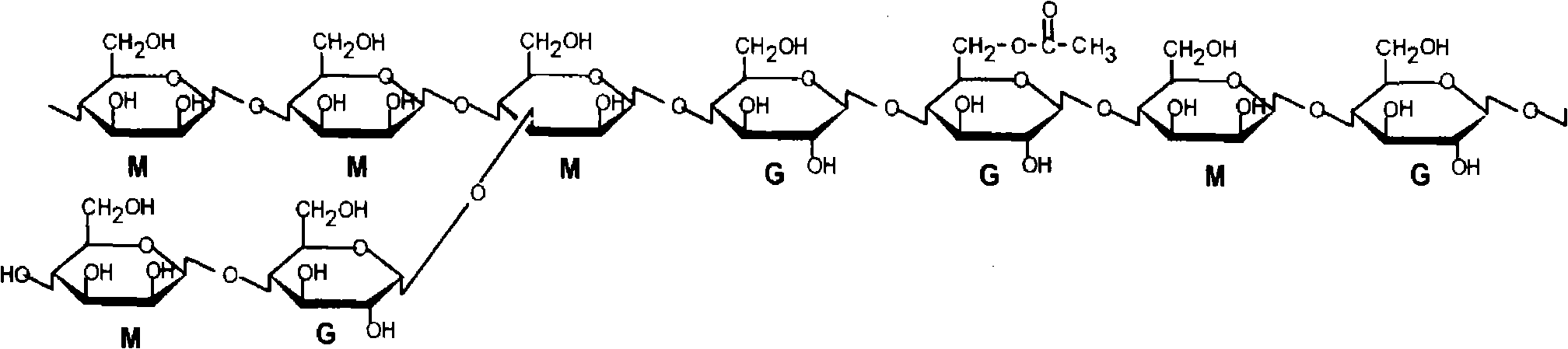

Degradable stephanoporate stent material for inducting osseous tissue regeneration and repair and preparation thereof

The invention discloses a degradable support material which induces the regeneration and repair of bone tissues and a preparation method thereof, pertaining to the technical field of the preparation of biomaterials. Degradable biomaterials, such as konjac glucan-mannan and hydroxyapatite / collagen protein or calcium phosphate / collagen protein composite powder, or hydroxyapatite or calcium phosphate are adopted as raw materials in the invention. Konjac glucan-mannan powder and hydroxyapatite / collagen protein or calcium phosphate / collagen protein composite powder, or hydroxyapatite or calcium phosphate are added into aqueous solution of an alkaline gelata and fully heated to form gel, and then after freeze-drying, the degradable porous support material is prepared. Not only does the materialhave simple preparation technology and low cost, but also the biomaterial prepared has good biocompatibility. Cell tests show that the material can be universally applied to bone operation and is theantibacterial porous material with adjustable degradation rate in vivo and can promote and induce the repair of the bone tissues, thereby having the wide application value in surgical operation.

Owner:KUNMING UNIV OF SCI & TECH

Fibroin bone cement biological adhesive and preparation method thereof

ActiveCN108744055AExcellent wet adhesionIncreased traumaSurgical adhesivesPharmaceutical delivery mechanismDiseaseInjectable bone

The invention belongs to the field of biomaterial preparation and biomedical application, and particularly relates to a fibroin bone cement biological adhesive with excellent wet state adhesion and immediate high strength mechanical properties and a preparation method thereof. According to the preparation method, polyphenols / hydroxyapatite or polyphenols / calcium phosphate is introduced into a fibroin solution system to prepare the fibroin bone cement biological adhesive with super strong adhesion. The adhesive has excellent wet state adhesion, and the novel injectable bone cement adhesive is provided for bone and joint hard tissue injury caused by trauma and pathological diseases. The adhesive can also be used as a hemostatic adhesive material for tissues such as skins, organs, blood vessels, nerves, muscles and mucous membranes.

Owner:FUZHOU UNIV

Method for preparing bacterial cellulose composite fish collagen wound dressing

ActiveCN103357060AImprove thermal stabilityImprove mechanical propertiesPeptide preparation methodsAbsorbent padsWound.exudateOperative incision

The present invention discloses a method for preparing bacterial cellulose composite fish collagen wound dressing and relates to a biological material preparation technology. The method comprises: selecting strains capable of secreting bacterial cellulose, activating and preparing seed mash, then inoculating the seed mash with a concentration of 30-90 wt% uniformly into a fermentation medium containing a fish collagen aqueous solution, fermenting for 3-7d and taking out a fermentation product. The fermentation product is purified and cut to obtain the bacterial cellulose composite fish collagen wound dressing which is evenly distributed with fish collagen macromolecules in three-dimensional network. The method is simple in preparation process, easy to operate, low in cost, and the resulting bacterial cellulose composite fish collagen wound dressing has the effects of stopping bleeding, moisturizing, breathability, absorbing wound exudate, and promoting wound healing, and can be used for treating skin wounds such as burn, scald and operative incision.

Owner:HAINAN GUANGYU BIOTECH

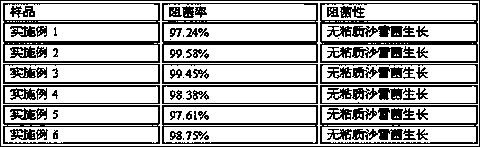

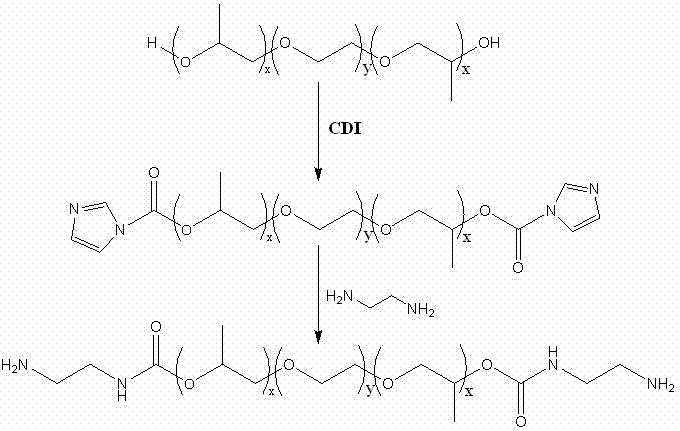

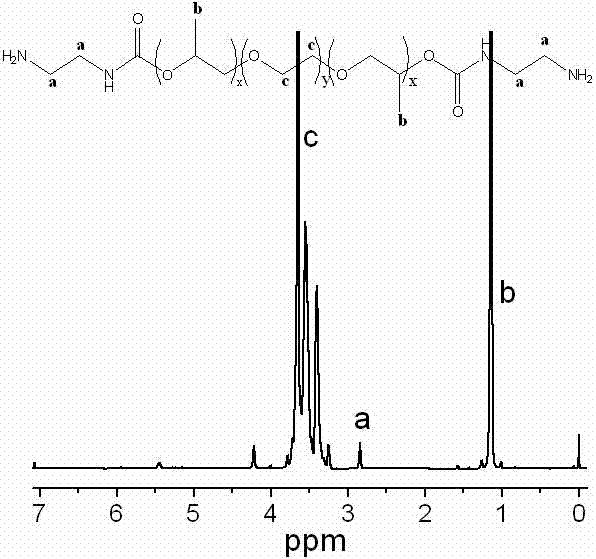

Amine-terminated polyether and continuous preparation method thereof

InactiveCN102212191AHigh efficiency of terminal amino groupHigh purityPeptide preparation methodsPharmaceutical non-active ingredientsEthylenediamineFreeze-drying

The invention belongs to the technical field of polymer synthesis and biomaterial preparation, and particularly discloses amine-terminated polyether and a continuous preparation method thereof. The preparation method comprises the following steps of: activating terminal hydroxyl of polyether by using N,N-carbonyl diimidazole (CDI), directly performing next reaction with ethanediamine without separating and purifying an activation product, performing rotary steaming on a product, dialyzing, and freeze-drying to obtain a product with high terminal amino group efficiency and high terminal amino group purity. The amine-terminated polyether can be used as a polymer synthesis intermediate or a biomaterial modified intermediate.

Owner:FUDAN UNIV

Charcoal preparation method and application thereof

InactiveCN107915215ARich pore sizeImprove stabilityGas treatmentDispersed particle filtrationParticulatesFreeze-drying

The invention discloses a charcoal preparation method and an application thereof and belongs to the field of biological material preparation. The method specifically comprises the following steps: firstly, soaking cleaned banana peel in a solution with a pore forming agent, performing freeze-drying, calcining in an inert atmosphere, performing ball-milling in a nitrogen-containing atmosphere, screening, and finally performing acid pickling, water washing and centrifugal collection, thereby obtaining charcoal. As the pore forming agent is used before the banana peel is carbonized, a carbonizedmaterial is relatively rich in pore; the carbonized material is further subjected to ball milling in the presence of a nitrogen-containing gas, so that not only is the specific surface area of the carbonized material increased, but also a nitrogen source is introduced into the charcoal; the prepared charcoal material is good in stability, can be applied to filtration of granules and organic matters in the atmosphere and adsorption of organic matters in water, can be used as a supercapacitor electrode material, and in addition can be repeatedly used.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

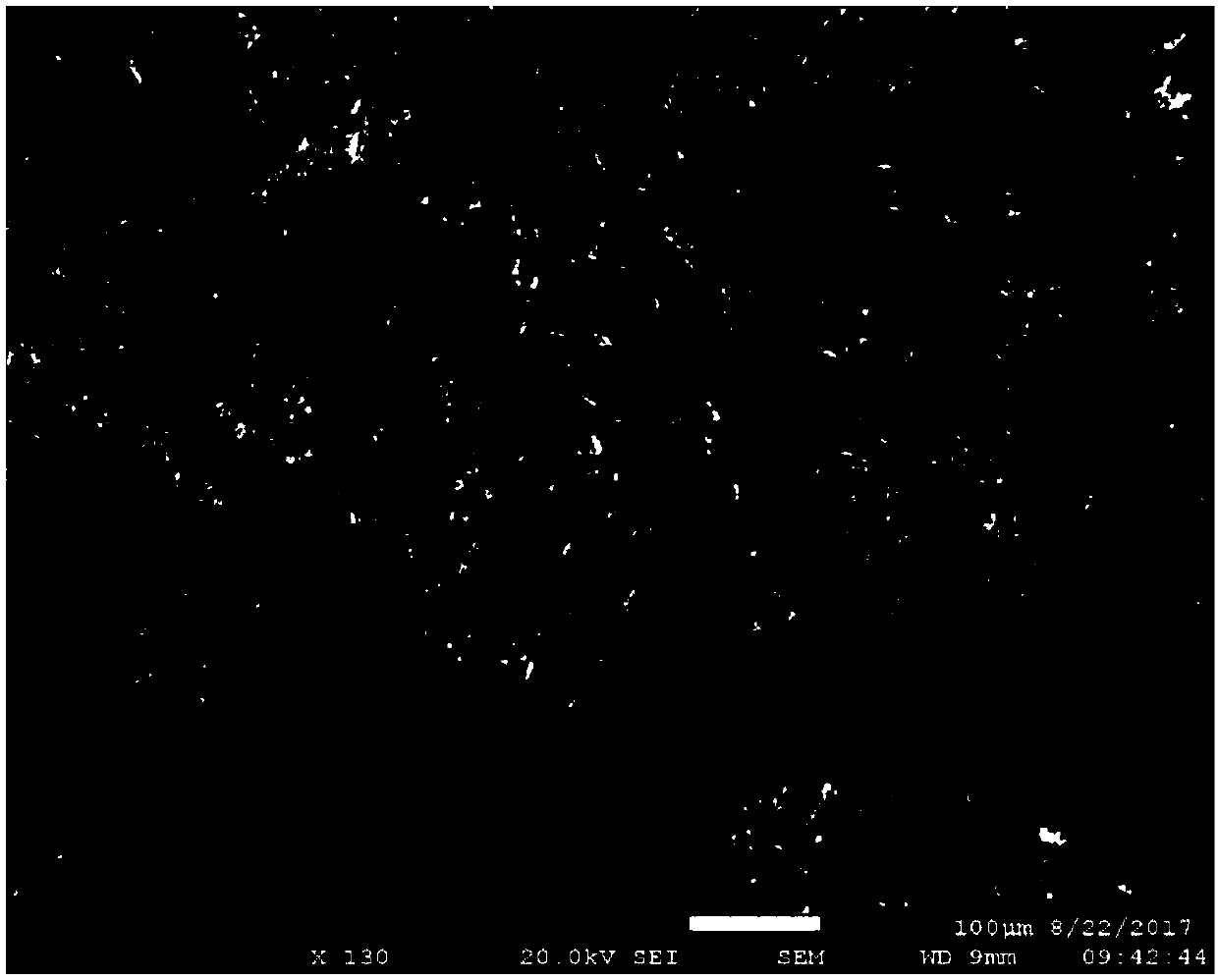

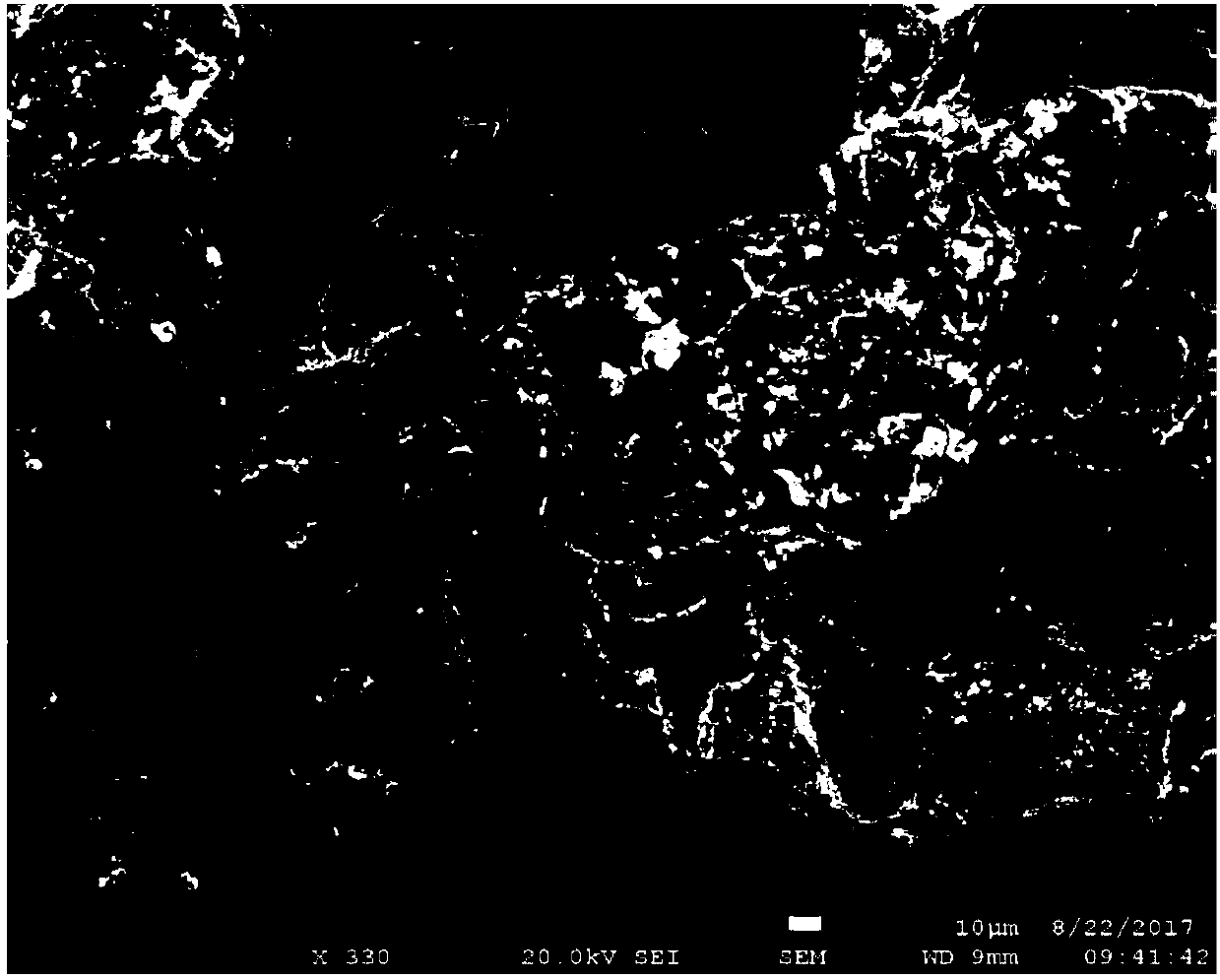

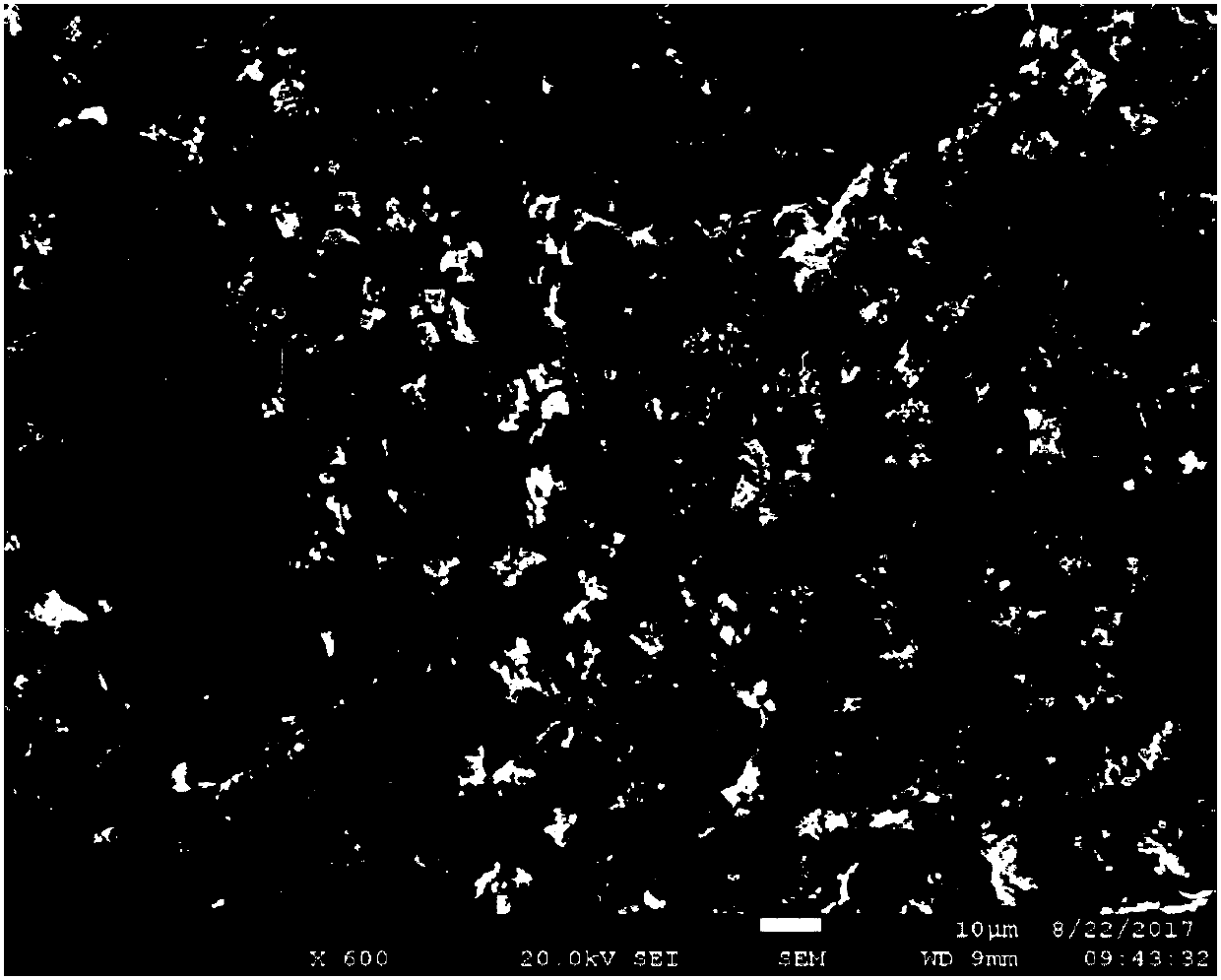

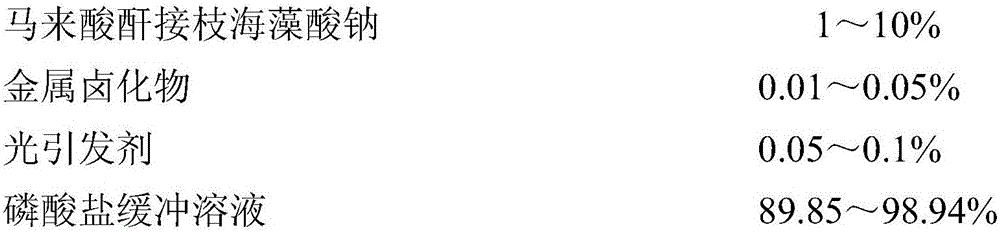

Preparation method of alginic acid hydrogel matrix for UV 3D printing

The invention relates to a preparation method of a hydrogel matrix, especially a preparation method of an alginic acid hydrogel matrix for UV 3D printing, and belongs to the technical field of biological material preparation. According to the preparation method, alkenyl groups are grafted on the molecular chains of sodium alginate prepared by a freeze-dry method, and after dissolving and mixing, the alginic acid hydrogel matrix for UV 3D printing is obtained. The preparation method adopts a freeze-drying technology under mixed solvent environment, the grafting rate of sodium alginate is largely improved, and the problem that the UV curing speed is slow due to low grafting rate is completely solved. The prepared alginic acid hydrogel matrix can rapidly solidify under the irradiation of UV light, the solid state can be maintained, moreover, in the presence of low concentration metal halides, the system can be further solidified, the hydrogel strength is improved, and the problems of conventional 3D printing hydrogel such as difficult moulding, collapse, and the like are overcome. The preparation method is simple, the cost is low, and the preparation method can be applied to industry easily.

Owner:济南科乐医药有限公司

Dissolving and filming method of egg shell membrane

InactiveCN1432592AReduce dosageGood removal effectOther chemical processesPharmaceutical non-active ingredientsOrganic acidPhosphate

The present invention belongs to the field of biological material preparing technology. Egg shell membrane is first dissolved completely in water solution of beta-thiopropionic acid and organic acid as cosolvent through heating to 80-95 deg.c and stirring; after centrifugal separatino and elimination of precipitate, the separated liquid is cast directly onto glass plate or steel plate and dried to form film; and the film is washed with methanol, neutralized with buffering phosphate solution, washed with deionized water, dried and peeled to obtain planar egg shell film. Without residual toxic solvent and crosslinking agent used, the egg shell film can be used widely.

Owner:TSINGHUA UNIV

Soft and hard tissue integrated regeneration-repair gradient three-dimensional fibrous scaffold and preparation method thereof

ActiveCN110772668ARegenerative repairWith mechanical propertiesElectro-spinningTissue regenerationFiberSynthetic Polymeric Macromolecules

The invention relates to a soft and hard tissue integrated regeneration-repair gradient three-dimensional fibrous scaffold and a preparation method thereof, and belongs to the technical field of preparation of medical biomaterials. According to the gradient three-dimensional fibrous scaffold, fiber lap joint is achieved, the porosity is greater than 90%, a perforated macroporous structure with thepore diameter being 30-150 [mu]m is included, the compressive strength reaches the MPa level, and the composition of the gradient three-dimensional fibrous scaffold from the top layer of the scaffoldto the bottom layer of the scaffold is of a bionic natural soft and hard tissue transition structure; and fibers are prepared from natural polymers with biocompatibility and synthetic polymers with synthetic polymer in a composited mode, wherein glycosaminoglycan components are added in composite fibers of the soft tissue layer scaffold, and hydroxylapatite components are deposited on the surfaces of composite fibers of a middle transition layer and a hard tissue layer scaffold. The gradient scaffold provided with different functional layers and meeting soft and hard tissue regeneration-repair demands is prepared, and cells and tissue in the scaffold can be induced in a layered mode to be simultaneously subjected to soft tissue differentiation and osteoblastic differentiation.

Owner:BEIJING UNIV OF CHEM TECH

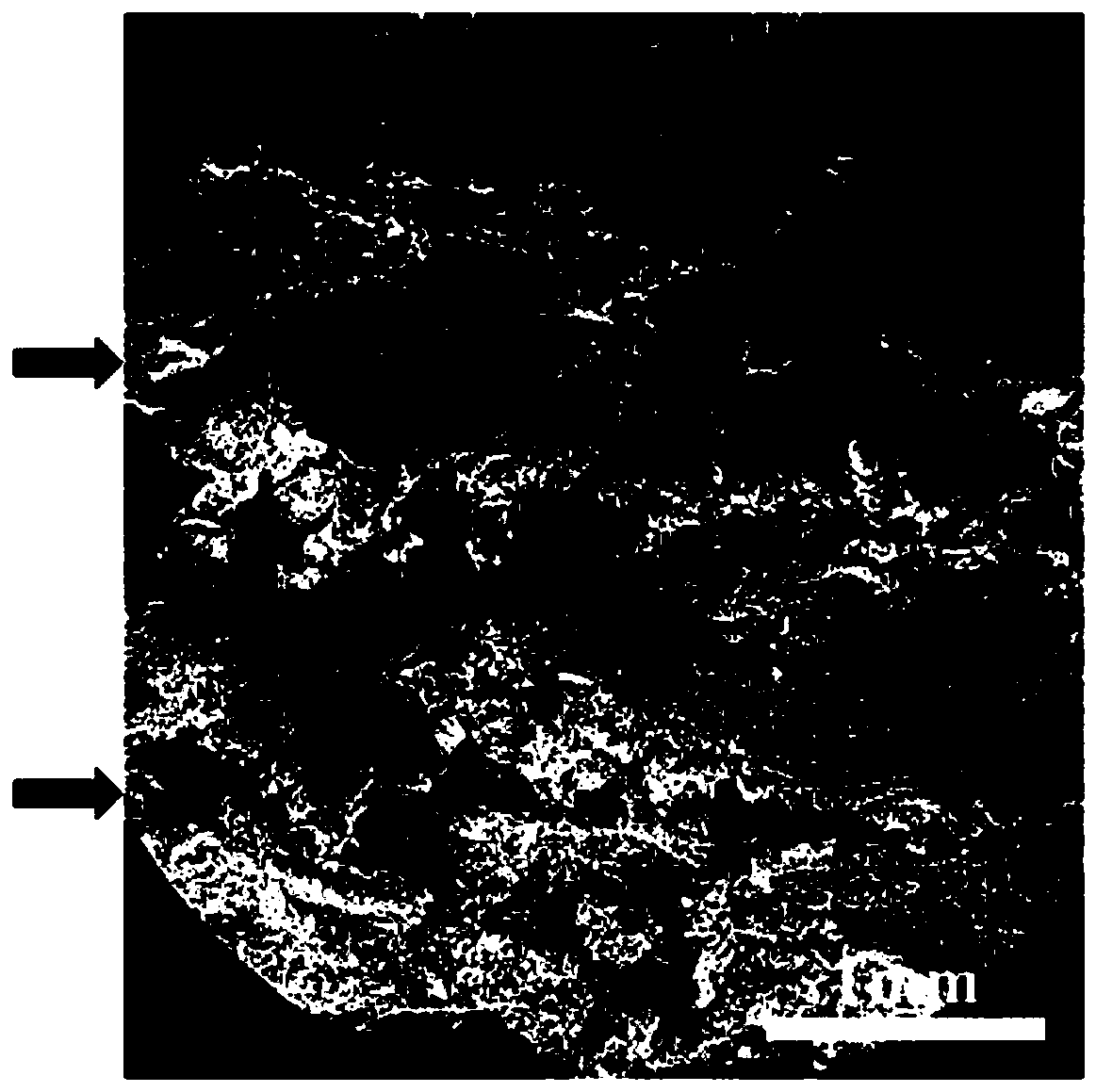

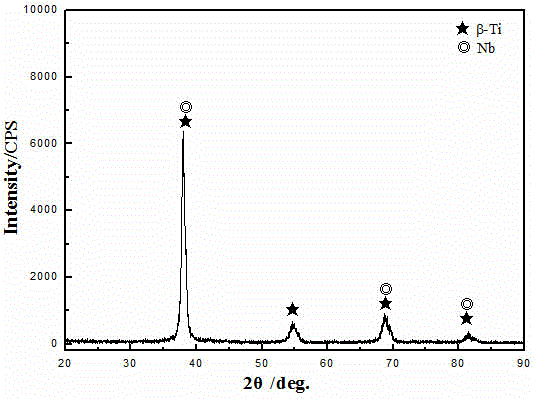

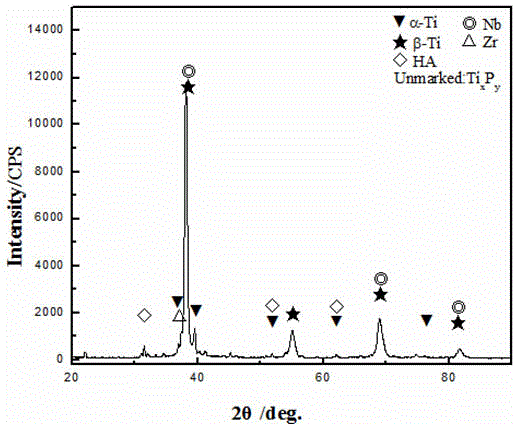

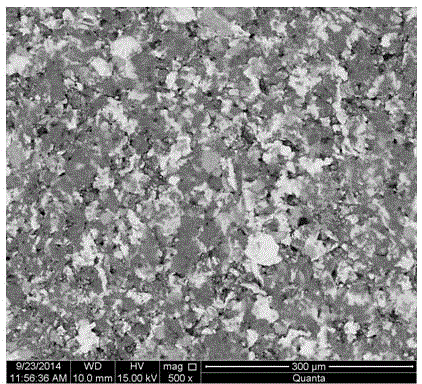

Preparation method of titanium-niobium-zirconium-based hydroxyapatite biological composite material

The invention discloses a preparation method of a titanium-niobium-zirconium-based hydroxyapatite biological composite material and belongs to the field of biomaterial preparation. The composite material of the invention employs titanium-niobium-zirconium alloy as a matrix, and hydroxyapatite as a bio-ceramic; and the weight of hydroxyapatite is 10-25% of that of the titanium alloy. The preparation process is as follows: filling a hydroxyapatite powder and a titanium alloy powder into a mill pot, sealing by alcohol, vacuumizing to 20-30Pa, milling for 6-8 h and drying in a vacuum oven; filling the dry powder into a graphite mold for cold forming; and finally carrying out spark plasma sintering with the sintering temperature at 1100 DEG C-1200 DEG C, first heating to 1000 DEG C by heating rate of in 100 DEG C / min, then heating to the sintering temperature by 25-50 DEG C / min and insulating for 6-10min with the pressure of 50-60MPa. The prepared biological composite material has elastic modulus of 25.4-45GPa, and has good mechanical properties and biocompatibility. The method of the invention is simple in process and low in production cost.

Owner:KUNMING UNIV OF SCI & TECH

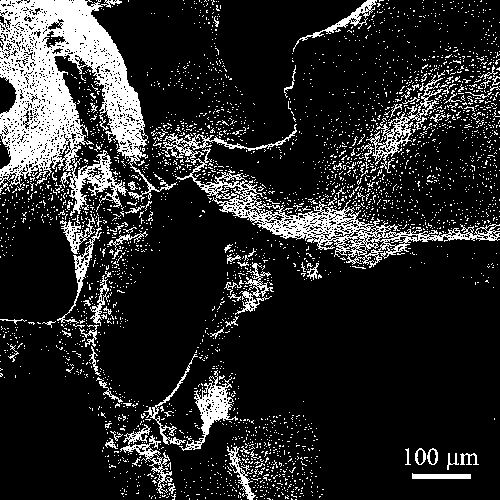

Method for preparing decellularization cartilage matrix material

PendingCN108653814AIntegrity guaranteedQuality assuranceTissue regenerationProsthesisSaline waterPorosity

The invention discloses a 'method for preparing a decellularization cartilage matrix material', and belongs to the technical field of biological material preparation. The method comprises the following steps: (1) carrying out immobilization treatment on human or animal cartilage tissue in an immobilization agent; (2) washing the cartilage tissue after the immobilization treatment by using an appreciate solution, wherein the washing time can be more times; (3) carrying out decellularization treatment on the washed cartilage tissue in an alkali solution; (4) carrying out soaking washing treatment on the cartilage tissue after the decellularization treatment, wherein the immobilization agent is glutaraldehyde, formaldehyde or peracetic acid, the appropriate solution may be distilled water, and the alkali solution is selected from 4-15% NaOH or KOH solutions, and a washing liquid used in soaking washing treatment is normal saline. The decellularization cartilage matrix material prepared byusing the method has a porosity of 70-90% and a pore size of 12-67mu m.

Owner:BEIJING QINGYUAN WEIYE BIO TISSUE ENG

First-aid dressing for large-area wound and preparation method thereof

PendingCN111588902AEasy to captureImprove adhesionPharmaceutical delivery mechanismAbsorbent padsAdhesiveBiocompatibility

The invention belongs to the field of biomaterial preparation and biomedical application, and particularly relates to a first-aid dressing for large-area wound and a preparation method thereof. The first-aid dressing comprises the following components: modified chitosan, biomass protein fibers and a polyphenol compound. The dressing is prepared by uniformly mixing the modified chitosan, the biomass protein fibers and the polyphenol compound at room temperature. The dressing prepared by the invention is high in hemostatic efficiency, high in bonding speed, wide in application range, strong in targeted antibacterial property, safe, non-toxic, good in biocompatibility and convenient to operate in a wet environment. The dressing is wide in raw material source, can be used for hemostasis and healing repair of various wound surfaces, is expected to replace traditional medical adhesives, and has a wide clinical application prospect.

Owner:YIGONG RUISI FUJIAN ENG RES CENT CO LTD

Preparation method of water-soluble ferroferric oxide nano-magnetic fluid

ActiveCN103922422AStrong magnetismImprove stabilityNanomagnetismMagnetic liquidsBiological materialsFERRIC IRON

The invention relates to a preparation method of a water-soluble ferroferric oxide nano-magnetic fluid, belonging to the technical field of nano material and biological material preparation. The method comprises the steps of hermetically heating a polyhydric alcohol-water solution of ferric iron salt, urea and tartaric acid or a mixed polyhydric alcohol-water solution of ferric iron salt, urea and tartaric acid to 100-200 DEG C, reacting for 6-48 hours to obtain water-soluble ferroferric oxide nanoparticles with diameters of 3-5 nanometers, and dispersing the ferroferric oxide nanoparticles in water, thus obtaining the ferroferric oxide nano-magnetic fluid. The method is simple in operation process, is low in production cost and is very suitable for industrial production.

Owner:ANHUI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Nano-rod-like structure hydroxyapatite and preparation method thereof

ActiveCN106966375AControl phaseSmall sizeMaterial nanotechnologyPhosphorus compoundsPhosphateControllability

The present invention relates to the field of biomaterial preparation, and provides nano-rod-like structure hydroxyapatite and a preparation method thereof. According to the preparation method, calcium lactate is adopted as a calcium source, creatine phosphate is adopted as a phosphorus source, and a hydrothermal reaction is performed to prepare the nano-rod-like structure hydroxyapatite. According to the present invention, the nano-rod-like structure hydroxyapatite has controlled appearance and controlled size, can be used as the biomedical material in the fields of drug delivery, bone defect repair and the like, and has good application prospect; the nano-rod-like structure hydroxyapatite is prepared by using the hydrothermal method, such that the reaction controllability is good; and the preparation process is simple, the operation is convenient, the complicated and expensive equipment is not needed, and the method is expected to achieve the industrial production.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

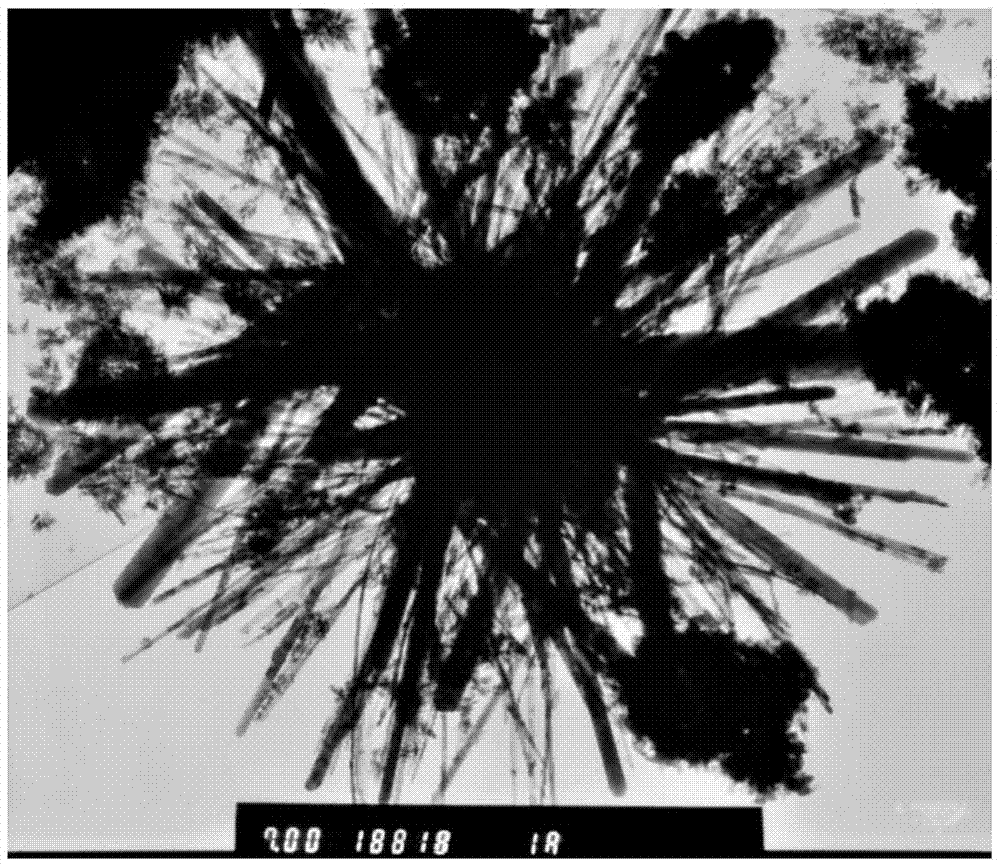

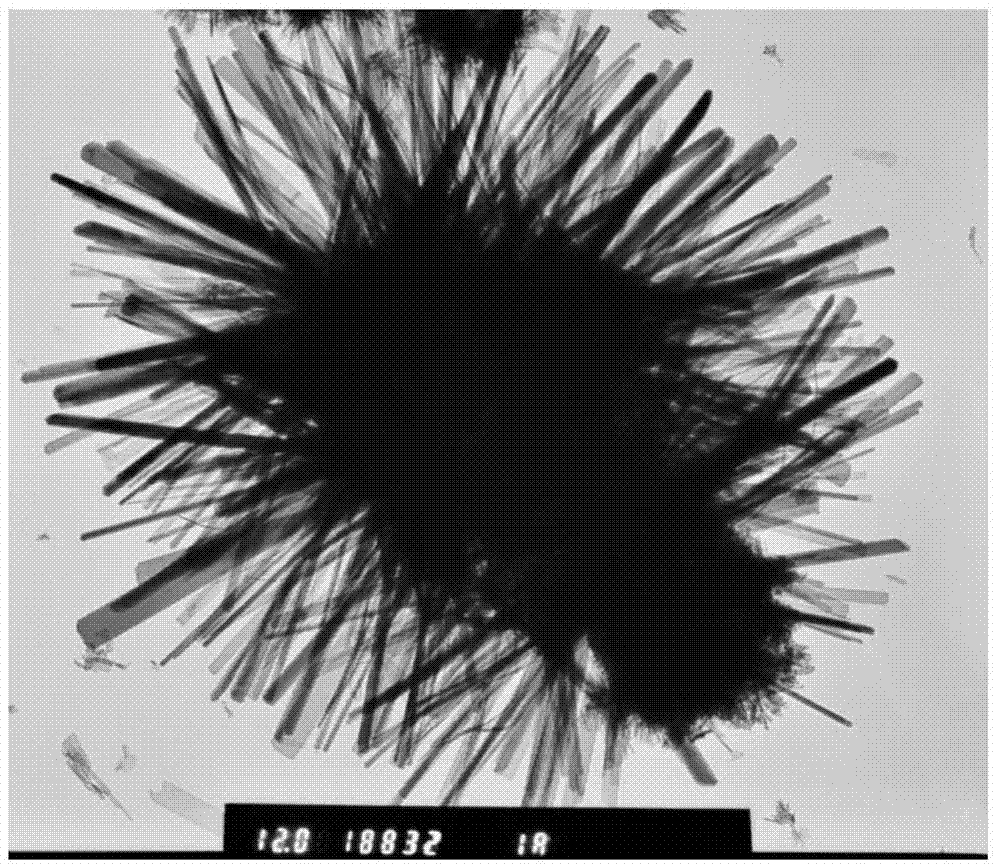

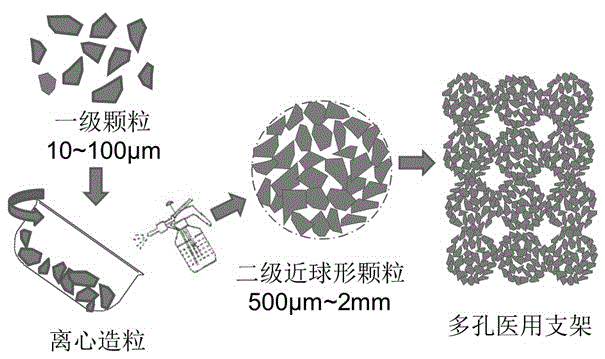

Preparation method of porous biomedical metal, ceramic or metal/ceramic composite material

InactiveCN103602844AEasy transferUniform porosity distributionProsthesisCeramicwareCeramic compositeBone grafting

The invention discloses a method of preparing a porous biomedical metal, ceramic or metal / ceramic composite material. The method comprises the following steps of based on a secondary pelletizing technology that metal micro powder or / and ceramic micro powder with narrow particle size distribution are used as primary particles, by using the primary particles as materials, adding a binder, carrying out secondary pelletizing by a centrifugal pelletizing method to obtain secondary nearly-spherical particles; forming the screened secondary nearly-spherical particles with the narrow particle size distribution in a mould cavity of a mould with special shape and dimension in a close packing mode, and sintering at a high temperature to obtain a medical material or product with a special porous structure and constitution. Compared with the preparation method of the porous biological material in the prior art, the preparation method disclosed by the invention has the advantages of simple process, good repeatability and the like, easily realizes bath production, is capable of preparing the porous biological material with a gradient porous structure and high mechanical strength at the same time, and is especially suitable for a bone grafting material for repairing bearing part bone defect.

Owner:SICHUAN UNIV

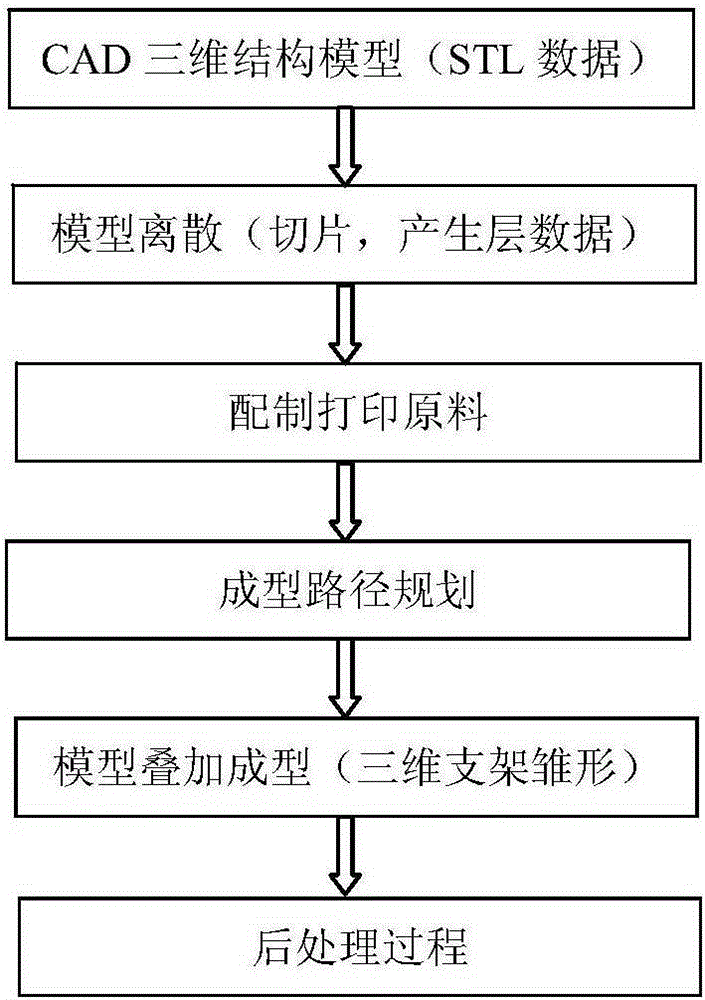

Rapid prototyping preparation method of implant material of plastic surgery

InactiveCN105232179AControl shape structureControl internal structureProsthesisPorositySoftware design

The invention discloses a rapid prototyping preparation method of an implant material of a plastic surgery. The method comprises the following steps of designing a three-dimensional structural model of a plastic part by using computer-aided design (CAD) software; importing CAD model data in a three-dimensional printer and performing slicing processing; preparing a biological material into a solution or directly adding the biological material in the three-dimensional printer; setting relevant parameters; starting the three-dimensional printer and printing the model layer by layer; and performing aftertreatment on a prototype to obtain the implant material of the plastic surgery or directly taking the prototype as the implant material of the plastic surgery. An implantable biological material is used for preparing a stent, immunological rejection is not caused, and biological compatibility is good; and moreover, the stent is prepared by a rapid prototyping technology, geometric profile, aperture, porosity and hole distribution of the stent are controlled accurately, a personalized plastic treatment scheme is formulated, a preparation technology is convenient and speedy, operation steps are simple, and an application prospect is wide.

Owner:SOUTH CHINA UNIV OF TECH

System and method for producing weighed portions of powder from at least one biological material at cryotemperatures

InactiveUS7823818B2Increase productionPrevent chemical and biological change in biologicalPreparing sample for investigationGrain millingMetallurgyBiological materials

A system and a method for producing a quantified defined portions of powder from at least one biological material at cryotemperature is shown, comprising means for grinding the biological material deposited in at least one first vessel to the powder; means for loosening the powder resulting from grinding the biological material in the first vessel; means for positioning at least one first opening in the first vessel, and means for transferring the quantified defined portions of powder in a plurality of second vessels by using the first opening as a transfer way.

Owner:MAX PLANCK GESELLSCHAFT ZUR FOERDERUNG DER WISSENSCHAFTEN EV

Preparation method and application of titanium alloy surface iodine-loaded antibacterial coating

ActiveCN111719172ALong release timePrevent explosive releaseAntifouling/underwater paintsSurgeryElectrophoresesBACTERIAL INFECTIOUS DISEASES

The invention discloses a preparation method and application of a titanium alloy surface iodine-loaded antibacterial coating and belongs to the technical field of preparation of medical and biologicalmaterials. The preparation method comprises the following steps: deoiling, blasting sand and grinding, carrying out ultrasonic washing, washing with acid, washing with water, carrying out micro-arc anodic oxidation treatment, washing with water, carrying out electrophoresis, washing with water and sealing pores. A non-metallic material with an antibacterial effect is deposited in a porous bioactive film layer prepared on the surface of a titanium alloy; the risk of dissolving metal ions in the using process is avoided; the antibacterial coating is semi-closed; the explosive release of the iodine material of the antibacterial coating is prevented; the slow release time of the iodine material is obviously prolonged; a more efficient and lasting antibacterial effect can be achieved; the antibacterial sterilization rate of the in-vitro coating reaches 100%; the bonding strength between the antibacterial coating and a titanium alloy substrate is greater than 53MPa; the antibacterial effects of medical apparatus and instruments are ensured; the bacterial infectious diseases caused by the medical apparatus and instruments are reduced; and the inflammations of implants are reduced.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com