Method for preparing bacterial cellulose composite fish collagen wound dressing

A technology of fish collagen and bacterial cellulose, applied in peptide preparation methods, chemical instruments and methods, medical science, etc., can solve problems such as restrictions on extracting collagen, doubts about the safety of livestock and poultry collagen products, etc., and achieve a simple preparation process Easy to operate, improve thermal stability and mechanical properties, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

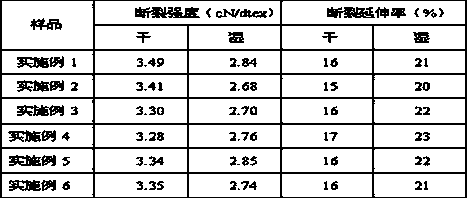

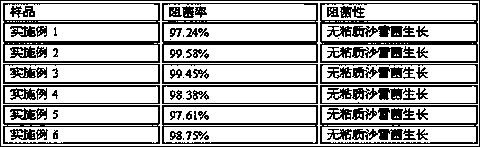

Embodiment 1

[0020] 1. Cut the fish body waste that has been cleaned of surface impurities into small pieces, and cut it into 50-mesh fish meal with a crusher; add distilled water and reaction enzymes that account for 3 times the mass of fish meal in a closed container and stir to make a slurry. The reaction enzyme is composed of neutral lipase and bromelain, the amount of reaction enzyme added accounts for 0.1% of the quality of fish meal, and the mass ratio of neutral lipase and bromelain is 1:4.

[0021] 2. Control the reaction temperature of the prepared slurry to 50° C., pH to 7, and stir for 2 hours to carry out the enzymatic hydrolysis reaction. Add 0.1% sodium hydroxide to the reacted slurry, heat to 90°C, and stir for 20 minutes; filter the slurry, and dialyze the filtrate for 7 days through a dialysis bag with a molecular weight cut-off of 100kDa, and evaporate and concentrate the retained solution to obtain fish collagen protein solution.

Embodiment 2

[0026] 1. Cut the fish body waste that has been cleaned of surface impurities into small pieces, and cut it into 100-mesh fish meal with a crusher; add distilled water and reaction enzymes that account for 5 times the mass of fish meal in a closed container and stir to make a slurry. The reaction enzyme is composed of neutral lipase and alkaline protease, the amount of reaction enzyme added accounts for 0.3% of the fishmeal mass, and the mass ratio of neutral lipase and alkaline protease is 1:4.

[0027] 2. Control the reaction temperature of the prepared slurry to 55° C., pH to 7.5, and stir for 1.5 hours to carry out the enzymatic hydrolysis reaction. Add 0.2% sodium hydroxide to the reacted slurry, heat to 80°C, and stir for 30 minutes; filter the slurry, and dialyze the filtrate for 7 days through a dialysis bag with a molecular weight cut-off of 150kDa, and evaporate and concentrate the retained solution to obtain fish collagen protein solution.

[0028] 3. The exudate a...

Embodiment 3

[0032] 1. Cut the fish body waste that has been cleaned of surface impurities into small pieces, and cut it into 150-mesh fish meal with a crusher; add distilled water and reaction enzymes that account for 7 times the mass of fish meal in a closed container and stir to make a slurry. The reaction enzyme is composed of neutral lipase and trypsin, the added amount of reaction enzyme accounts for 0.5% of the mass of fish meal, and the mass ratio of neutral lipase and trypsin is 1:3.

[0033] 2. Control the reaction temperature of the prepared slurry to 70° C., pH to 7.5, and stir for 1 hour to carry out the enzymatic hydrolysis reaction. Add 0.3% sodium hydroxide to the reacted slurry, heat to 90°C, and stir for 30 minutes; filter the slurry, and dialyze the filtrate for 7 days through a dialysis bag with a molecular weight cut-off of 200kDa, and evaporate and concentrate the retained solution to obtain fish collagen protein solution.

[0034] 3. The exudate after dialysis is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com