Injectable porous bone cement and preparation method thereof

A porous bone and injectable technology, applied in medical science, prosthesis, etc., can solve the problems of bone cement curing time prolongation, leakage, etc., and achieve the effect of easy implementation, simple process, and superior comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

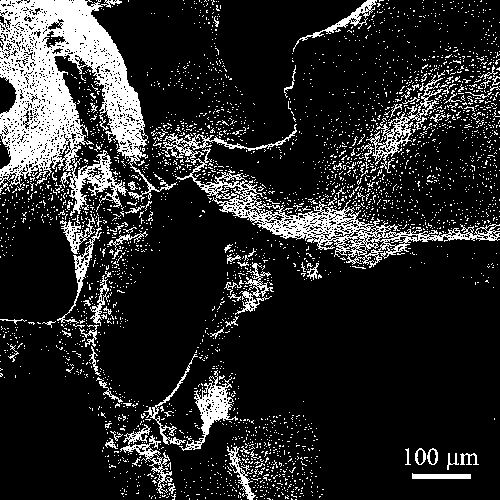

Image

Examples

Embodiment 1

[0024] Example 1: Add commercial calcium carbonate with a mass fraction of 6.5% and anhydrous sodium sulfate powder between 300-400 mesh with a mass fraction of 4.5% to the β-tricalcium phosphate bone cement powder, use absolute ethanol as the medium, and rotate at a speed of 500 rpm, ball milling for 12 h, centrifugation, heating and drying, and crushing to obtain bone cement powder. Prepare an aqueous solution with a mass fraction of chitosan of 2%, a mass fraction of hydroxypropylmethylcellulose of 1%, and a mass fraction of citric acid of 20% as a solidification solution. The bone cement powder and curing liquid were mixed at a solid-to-liquid ratio of 1 g: 0.45 ml to prepare a fast-curing, collapse-resistant injectable porous bone cement. The initial setting time was determined to be 25 minutes according to the standard ASTM C191. After the curing reaction was carried out for 1 hour, it did not collapse when exposed to water. It was cured for 24 hours at a temperature of ...

Embodiment 2

[0025] Example 2: To the mixed powder of β-tricalcium phosphate / hydroxyapatite (mass ratio 7:3), add commercial calcium carbonate with a mass fraction of 6.5% and anhydrous calcium carbonate with a mass fraction of 4.5% between 300-400 mesh Sodium sulfate powder, with absolute ethanol as the medium, ball milled at 500 rpm for 12 h, centrifuged, heated and dried, and mashed to obtain bone cement powder. Prepare an aqueous solution with a mass fraction of chitosan of 0.05%, a mass fraction of hydroxypropyl methylcellulose of 3%, and a mass fraction of citric acid of 20% as a solidification solution. The bone cement powder and curing liquid were mixed at a solid-to-liquid ratio of 1 g: 0.5 ml to prepare a fast-curing, collapse-resistant injectable porous bone cement. The initial setting time was 22 minutes as measured by the standard ASTM C191. After the curing reaction was carried out for 1 h, it did not collapse when exposed to water, and was cured for 24 h at a temperature of ...

Embodiment 3

[0026] Example 3: Adding 8% mass fraction of commercial calcium carbonate and 5% mass fraction of anhydrous calcium carbonate between 300-400 mesh to the mixed powder of β-tricalcium phosphate / hydroxyapatite (mass ratio 7:3) Sodium sulfate powder, with absolute ethanol as the medium, ball milled at 500 rpm for 12 h, centrifuged, heated and dried, and mashed to obtain bone cement powder. Prepare an aqueous solution with a mass fraction of chitosan of 2%, a mass fraction of hydroxypropylmethylcellulose of 1%, and a mass fraction of citric acid of 30% as a solidification solution. The bone cement powder and curing liquid were mixed at a liquid-solid ratio of 0.5 ml: 1 g to prepare a fast-setting, collapse-resistant injectable porous bone cement. The initial setting time was 13 minutes as measured by the standard ASTM C191. After the curing reaction was carried out for 45 minutes, it did not collapse in contact with water, and was cured for 24 hours at a temperature of 37 °C and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solidification time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com