3D bio-printing medical dressing and preparation method thereof

A bioprinting and biomaterial technology, applied in the field of biomedical material preparation, can solve problems such as poor moisturizing and hemostasis, bacterial growth, wound adhesion, etc., and achieve the effects of promoting wound healing, good air permeability, and good water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

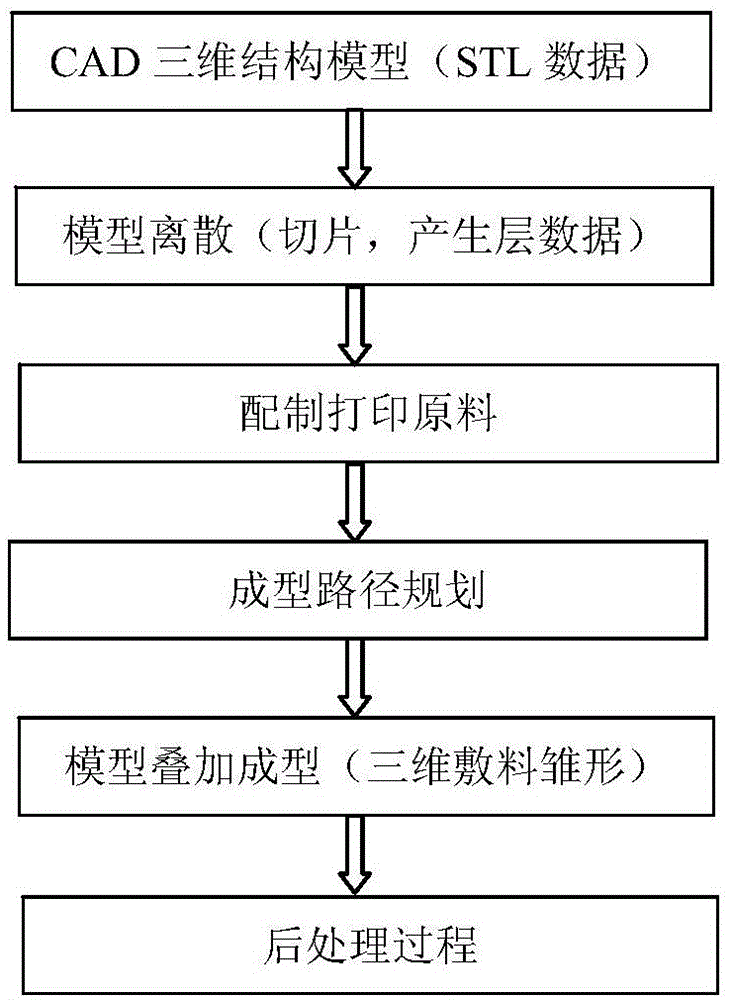

[0028] (1) Utilize computer-aided design (CAD) software to design a three-dimensional structural model of the wound dressing, and save the three-dimensional model as an STL format file, then import it into a three-dimensional printer, and perform layering processing with layering software;

[0029] (2) Add 15g of decellularized collagen to 100ml of deionized water, stir for 2 hours until completely dissolved to obtain an aqueous solution of decellularized collagen, filter it, add the filtrate into the barrel of the 3D printer, centrifuge and let it stand for 24 hours; in the VisualMachines software Set the printing temperature to room temperature, platform temperature to 10°C, needle size to 0.3mm, extrusion pressure to 1.2bar, extrusion speed to 3.0mm / s, hole diameter to 0.8mm, and internal structure to 0° and 90°staggered arrangement , with a layer thickness of 0.24mm; then start the 3D printer to print the 3D structure model of the wound dressing with a regular porous struct...

Embodiment 2

[0032] (1) Utilize computer-aided design (CAD) software to design a three-dimensional structural model of the wound dressing, and save the three-dimensional model as an STL format file, then import it into a three-dimensional printer, and perform layering processing with layering software;

[0033] (2) Add 10g of decellularized collagen and 3g of sodium alginate into 100ml of deionized water, stir for 2 hours until completely dissolved to obtain a mixed aqueous solution of decellularized collagen and sodium alginate, then filter it, and add the filtrate to the barrel of the 3D printer , and let stand for 24 hours after centrifugation; then in the VisualMachines software, set the printing temperature to room temperature, platform temperature to 10°C, needle size to 0.2mm, extrusion pressure to 2.8bar, extrusion speed to 1.5mm / s, and aperture to 0.5 mm, set the internal structure to be staggered at 0° and 90°, and the layer thickness is 0.16mm; then start the 3D printer to print ...

Embodiment 3

[0036] (1) Utilize computer-aided design (CAD) software to design a three-dimensional structural model of the wound dressing, and save the three-dimensional model as an STL format file, then import it into a three-dimensional printer, and perform layering processing with layering software;

[0037] (2) Add 10g of decellularized collagen and 3g of hyaluronic acid into 100ml of deionized water, stir for 2 hours until completely dissolved to obtain a mixed aqueous solution of decellularized collagen and hyaluronic acid, then filter it, and add the filtrate to the barrel of the 3D printer , after centrifugation, let it stand for 24 hours; then set the printing temperature to room temperature, the platform temperature to 5°C, the needle size to 0.4mm, the extrusion pressure to 1.0bar, the extrusion speed to 4.0mm / s, and the aperture to 0.8 in the VisualMachines software. mm, set the internal structure to be staggered at 0° and 90°, and the layer thickness is 0.32mm; then start the 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com