Charcoal preparation method and application thereof

A technology of biochar and banana peel, applied in the direction of carbon preparation/purification, separation methods, chemical instruments and methods, etc., can solve the problems of limited pore size and low carbonization temperature of banana peel, achieve rich pore size, increase specific surface area, stable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing biochar, comprising the steps of:

[0028] (1) Wash the surface of the banana peel, soak it in 10wt% sodium hydroxide solution at 50°C for 10h, the concentration of the banana peel in the solution is 1000mg / mL, and freeze-dry it at -51°C for 24h;

[0029] (2) under the Ar atmosphere that air velocity is 200sccm, the banana peel after step (1) is calcined at 1000 ℃ for 5h;

[0030] (3) Under a nitrogen atmosphere with an air velocity of 50 sccm, the carbonized material obtained after calcining was ball milled for 4 hours with a ball with a diameter of 20 mm, the ball-to-material ratio was 5:1, and the rotating speed was 30 rpm, and then passed through a 200-mesh sieve;

[0031] (4) The undersize was acid-washed in 1M hydrochloric acid, washed with water to pH=7, and collected by centrifugation to obtain biochar.

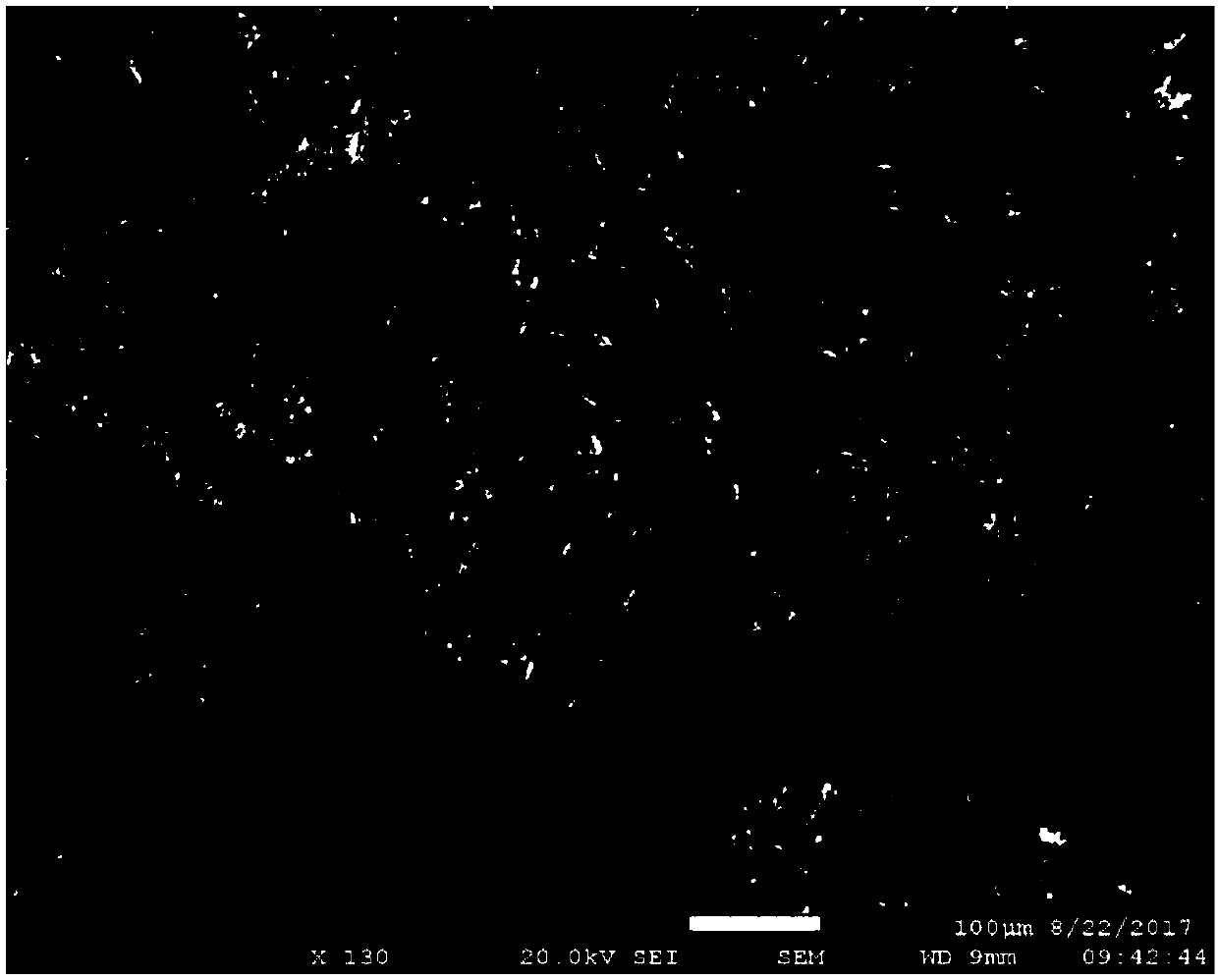

[0032] figure 1 It is a scanning electron microscope (SEM) picture of the biochar obtained in Example 1. The specific surface area of...

Embodiment 2

[0035] A method for preparing biochar, comprising the steps of:

[0036] (1) Wash the surface of the banana peel, soak it in 5wt% ammonium bicarbonate solution at 40°C for 0.5h, the concentration of the banana peel in the solution is 100mg / mL, and freeze-dry it at -51°C for 24h;

[0037] (2) under the Ar atmosphere that air velocity is 50sccm, the banana peel after step (1) is calcined at 500 ℃ for 10h;

[0038] (3) Under a nitrogen atmosphere with an air velocity of 300 sccm, the carbonized material obtained after calcining in step (2) was ball-milled for 10 h with a ball with a diameter of 10 mm, the ball-to-material ratio was 10:1, and the rotating speed was 50 rpm, and then passed through 100 mesh screen;

[0039] (4) The undersize was acid-washed in 2M hydrochloric acid, washed with water to pH=7, and collected by centrifugation to obtain biochar.

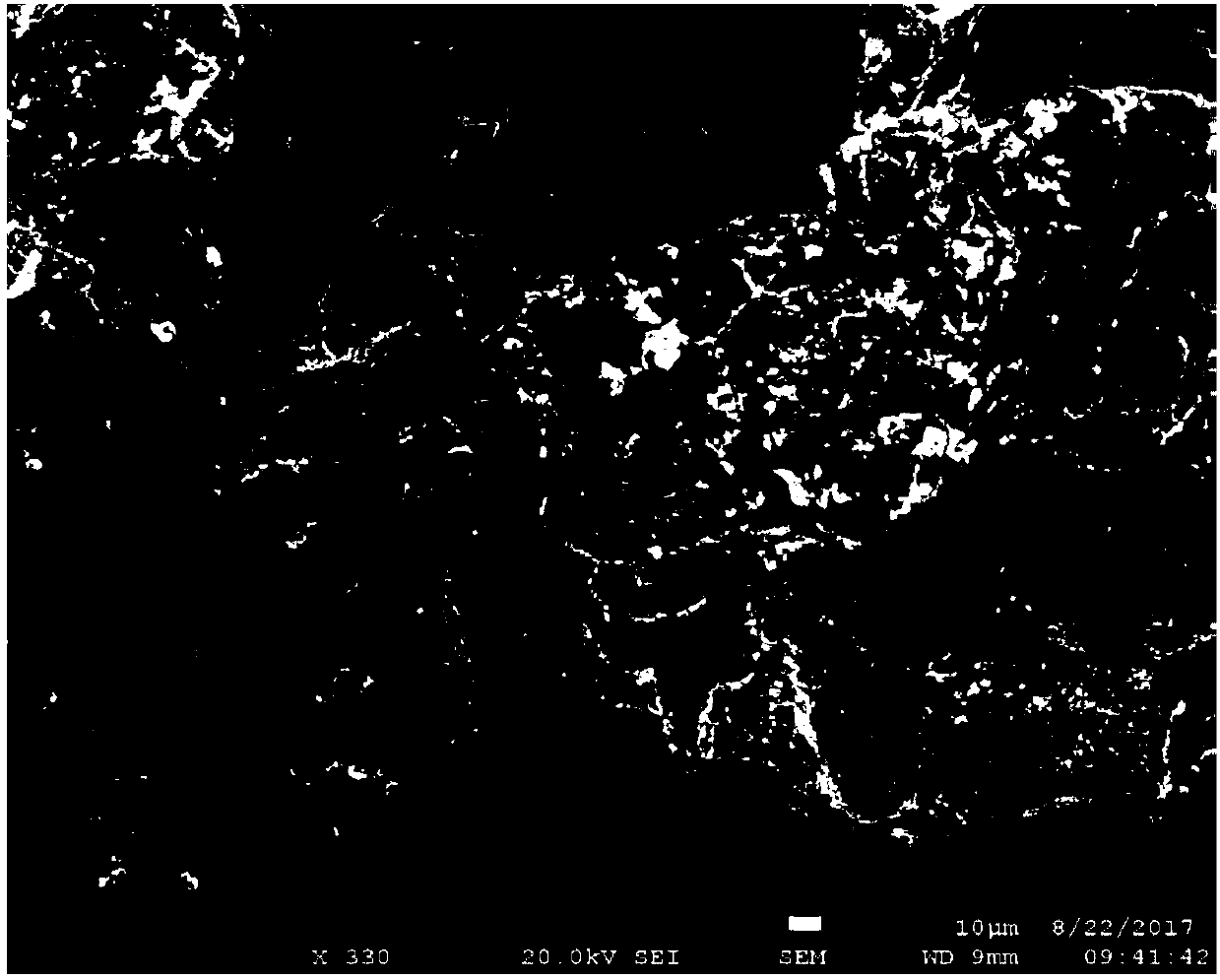

[0040] figure 2 It is a scanning electron microscope (SEM) picture of the biochar obtained in Example 2. The nitrogen c...

Embodiment 3

[0043] The preparation method of biochar comprises the following steps:

[0044] (1) Clean the surface of the banana peel, soak it in 20wt% urea solution at 10°C for 3h, the concentration of the banana peel in the solution is 800mg / mL, and freeze-dry it at -51°C for 12h;

[0045] (2) N at an air velocity of 100 sccm 2 Under the atmosphere, the banana peel treated in step (1) was calcined at 800°C for 4h;

[0046] (3) Under the ammonia gas atmosphere whose air velocity is 200 sccm, the carbonized material obtained after calcining in step (2) is ball-milled for 8 hours with a ball with a diameter of 10 mm, the ball-to-material ratio is 10:1, and the rotating speed is 60 rpm. Mesh sieve;

[0047] (4) The undersize was acid-washed in 2M nitric acid, washed with water to pH=7, and collected by centrifugation to obtain biochar.

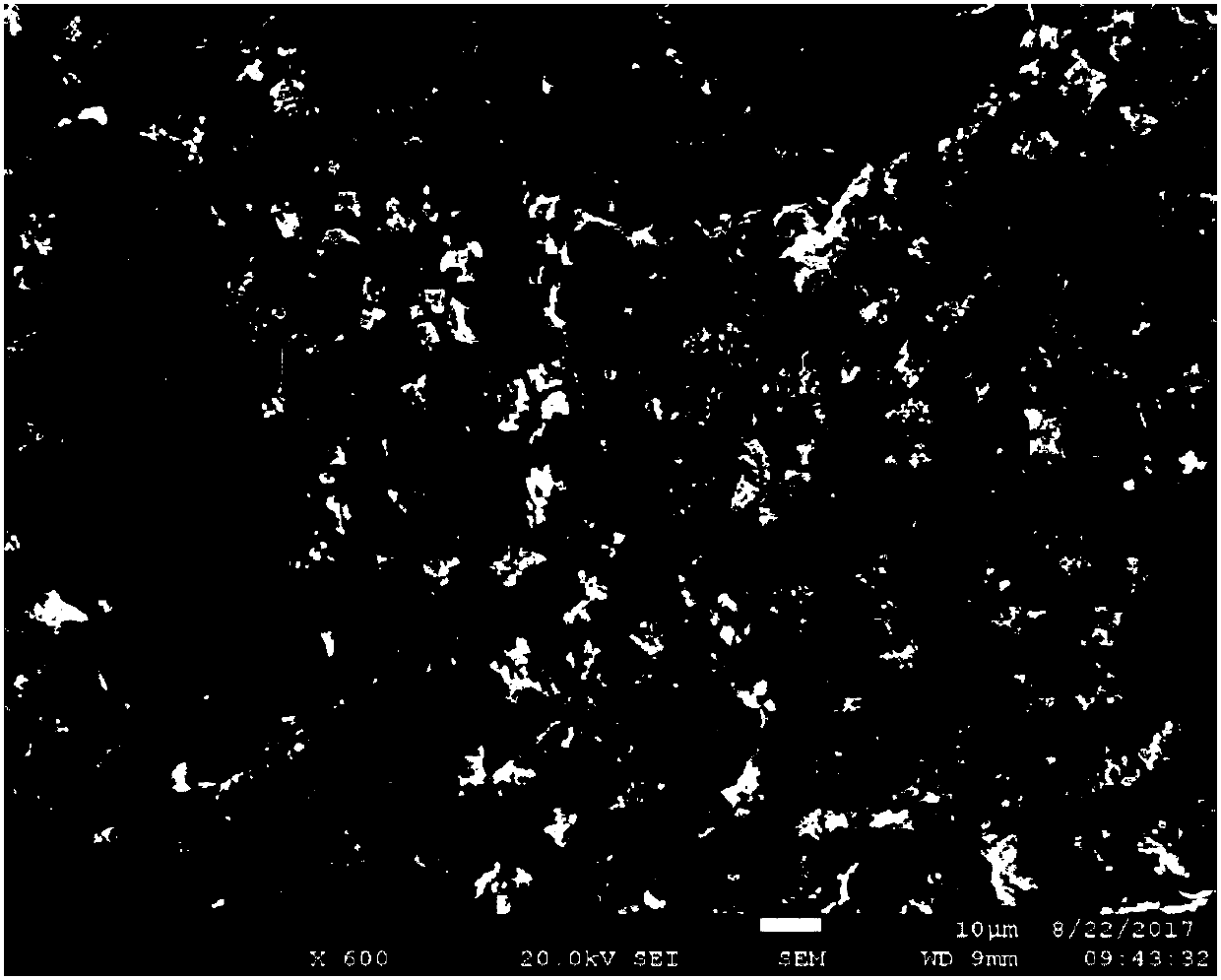

[0048] image 3 It is a scanning electron microscope (SEM) picture of the biochar obtained in Example 3. The biochar has a large specific surface area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com