Preparation method of soy sauce residue biochar heavy metal soil conditioner and product thereof

A technology of soil improver and soy sauce residue, which is applied in the field of soil remediation, can solve problems such as the inability to coordinate the relationship between heavy metal adsorption and soil conditioning, the inability to use soil remediation requirements, and unsatisfactory enzyme activity of conditioners, etc., to achieve fast adsorption efficiency and promote Effects of growth and development, increase in pore structure and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

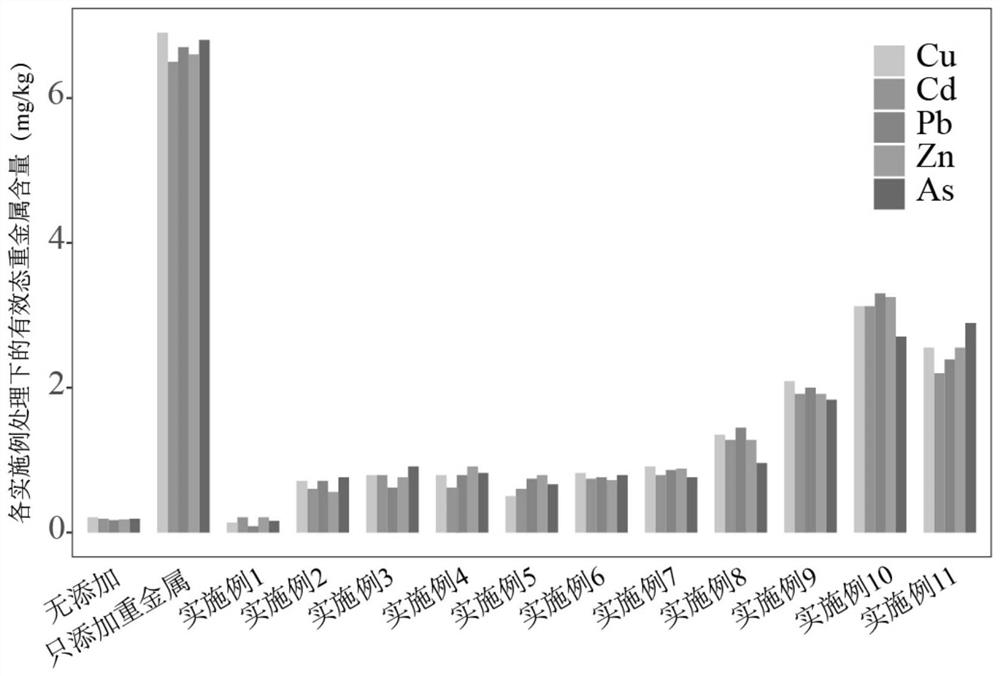

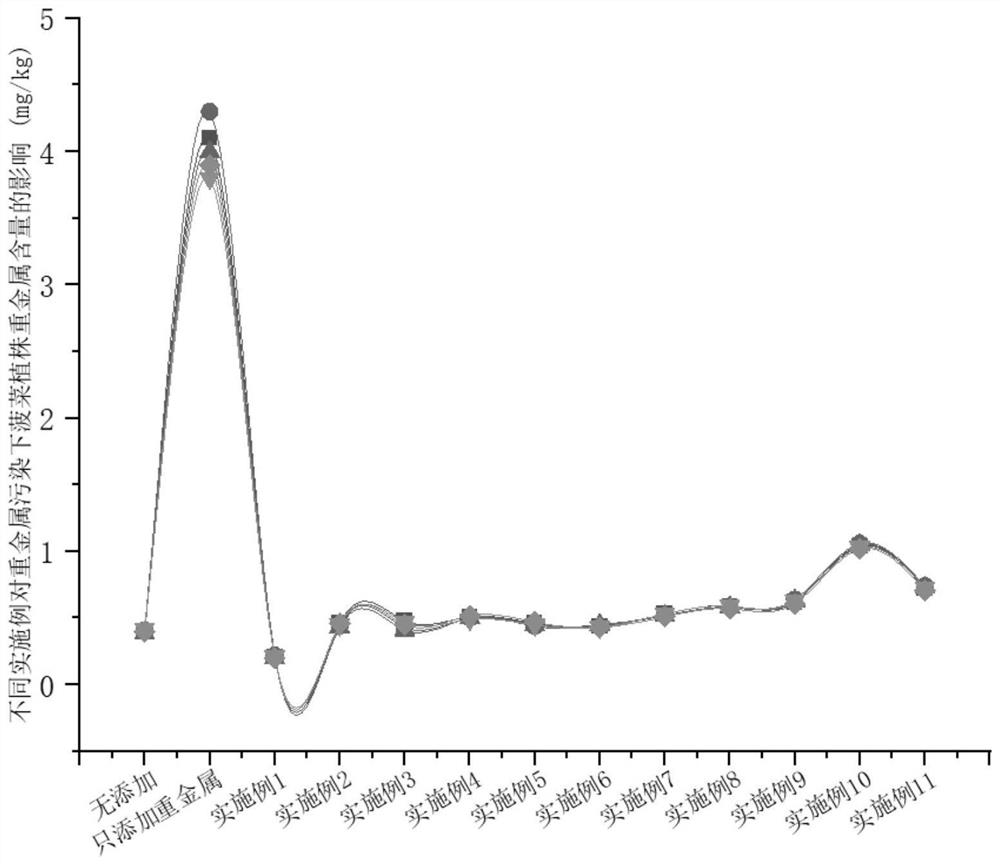

Examples

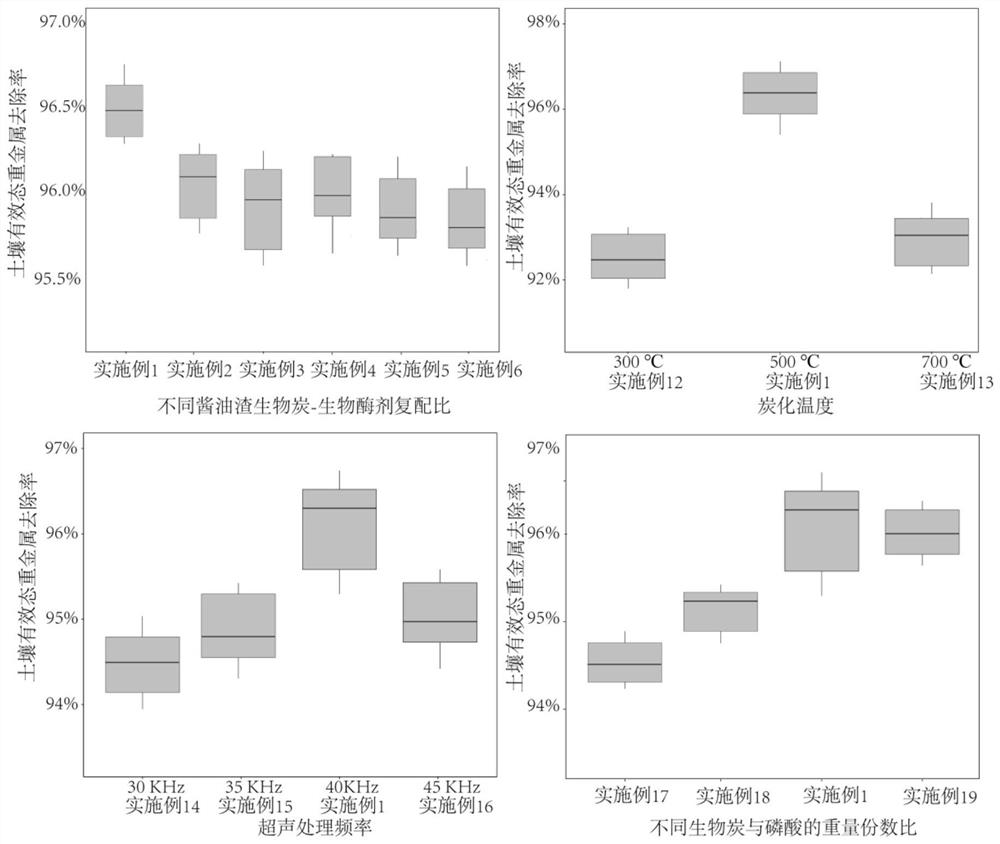

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of soy sauce residue biochar heavy metal soil conditioner, comprising:

[0036] (1) Preparation of raw biochar: Dry the soy sauce residue at 80°C to constant weight and grind through an 80-mesh sieve. 2 Under filling, the temperature was raised to 600°C at 10°C / min and maintained for 2 hours, then the temperature was lowered to 300°C at 10°C / min and kept at a constant temperature for 30 minutes, and the temperature was naturally lowered to room temperature to obtain the original soy sauce residue biochar.

[0037] (2) Modified desalination after carbonization: in parts by weight, every part of original soy sauce residue biochar is soaked in deionized water until the removal rate of salt content reaches more than 70%, and then mixed with 3 parts of 75% H 3 PO 4 Soak in the solution for 10 hours to modify and further desalinate, filter out the biochar and wash it with deionized water until neutral.

[0038] (3) ...

Embodiment 2

[0041] Compared with Example 1, this example contains 15 parts of biochar and 5 parts of biological enzyme agent in soy sauce residue biochar heavy metal soil amendment, and other preparation process conditions are all the same as in Example 1.

Embodiment 3

[0043] Compared with Example 1, this example contains 15 parts of biochar and 3 parts of biological enzyme agent in soy sauce residue biochar heavy metal soil amendment, and other preparation process conditions are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com