Preparation method of water-soluble ferroferric oxide nano-magnetic fluid

A technology of ferroferric oxide and nano-magnetic fluid, which is applied in the direction of nano-magnetism, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of complex organic coating or modification process, and achieve easy control of the preparation process and preparation Simple process and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Dissolve 2.7 grams of ferric nitrate nonahydrate in a mixed solution of 50 ml of ethylene glycol and 50 ml of water, add 1.5 grams of L-tartaric acid, stir for 20 minutes, then add 4.8 grams of urea, and stir to dissolve;

[0026] (2) Then transferred to a polytetrafluoroethylene reactor, placed in an oven and heated to 140 o C, reacted for 36 hours to obtain a precipitate;

[0027] (3) Separate the precipitate with a magnet and wash with absolute ethanol;

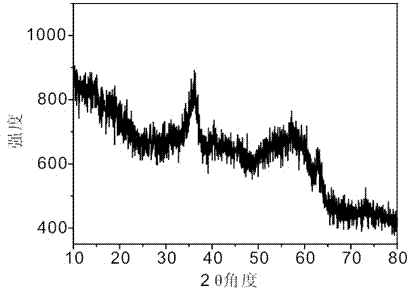

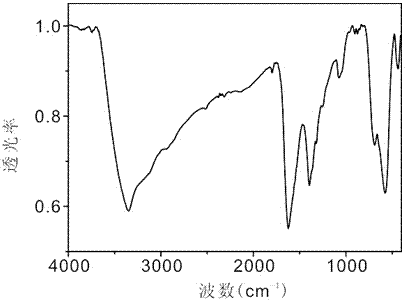

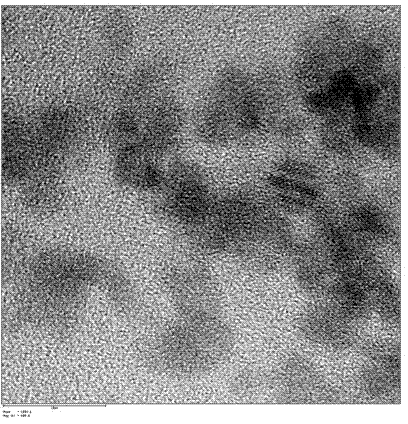

[0028] (4) The product was placed in an oven and vacuum-dried at 40 o C for 12 hours to obtain water-soluble ferric oxide nanoparticles with a diameter of 3-5 nm.

[0029] (5) Disperse 0.1 g of Fe3O4 nanoparticles in 5 ml of water to obtain Fe3O4 nano-magnetic fluid.

[0030]

Embodiment 2

[0032] (1) Dissolve 1.8 grams of ferric chloride hexahydrate in a mixed solution of 50 ml of ethylene glycol and 50 ml of water, add 1.5 grams of L-tartaric acid, stir for 20 minutes, then add 4.8 grams of urea, stir to dissolve;

[0033] (2) Then transferred to a polytetrafluoroethylene reactor, placed in an oven and heated to 140 o C, reacted for 40 hours to obtain a precipitate;

[0034] (3) Separate the precipitate with a magnet and wash with absolute ethanol;

[0035] (4) The product was placed in an oven and vacuum-dried at 40 o C for 12 hours to obtain water-soluble ferric oxide nanoparticles with a diameter of 3-5 nm.

[0036] (5) Disperse 0.2 g ferroferric oxide nanoparticles in 10 ml water to obtain ferroferric oxide nano-magnetic fluid.

[0037]

Embodiment 3

[0039] (1) Dissolve 2.7 grams of ferric sulfate in a mixed solution of 50 ml of ethylene glycol and 50 ml of water, add 1.5 grams of L-tartaric acid, stir for 20 minutes, then add 4.8 grams of urea, stir to dissolve;

[0040] (2) Then transferred to a polytetrafluoroethylene reactor, placed in an oven and heated to 200 o C, reacted for 48 hours to obtain a precipitate;

[0041] (3) Separate the precipitate with a magnet and wash with absolute ethanol;

[0042] (4) The product was placed in an oven and vacuum-dried at 40 o C for 12 hours to obtain water-soluble ferric oxide nanoparticles with a diameter of 3-5 nm.

[0043] (5) Disperse 0.1 g ferroferric oxide nanoparticles in 10 ml water to obtain ferroferric oxide nano-magnetic fluid.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com