Combined high-performance pentamaran ship with rotating body

A composite, high-performance technology, applied in the direction of using auxiliary nozzles or propellers to reduce ship motion, etc., can solve problems such as low efficiency and poor overall economy, and achieve the effect of reducing structural weight, good effect, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

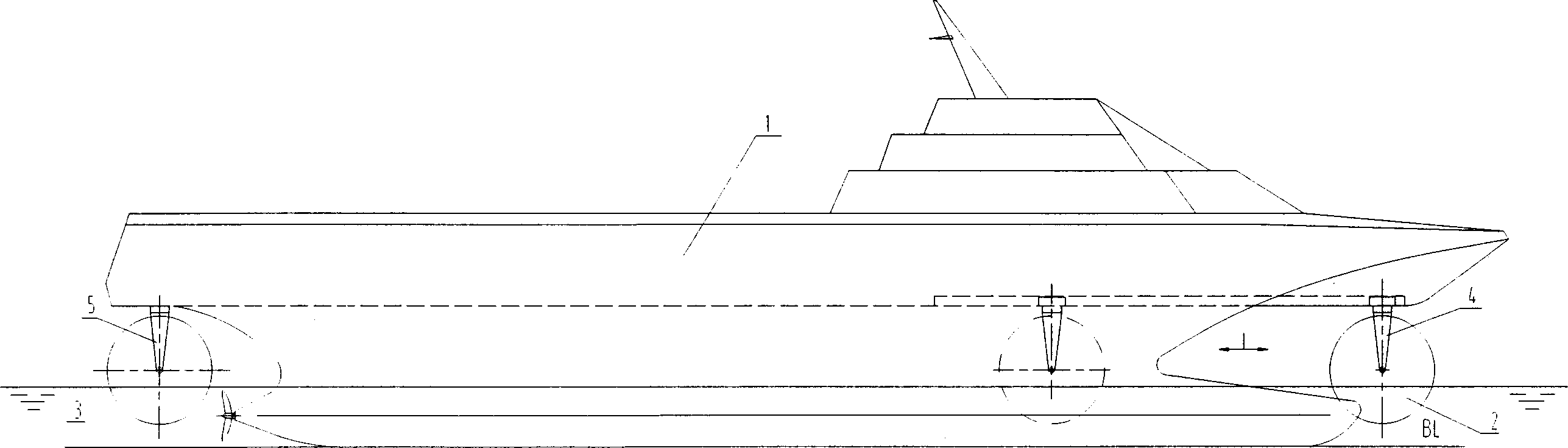

[0027] use as figure 1 Ordinary catamaran as shown; or small waterplane area catamaran; or medium waterplane area catamaran; or wave piercing catamaran.

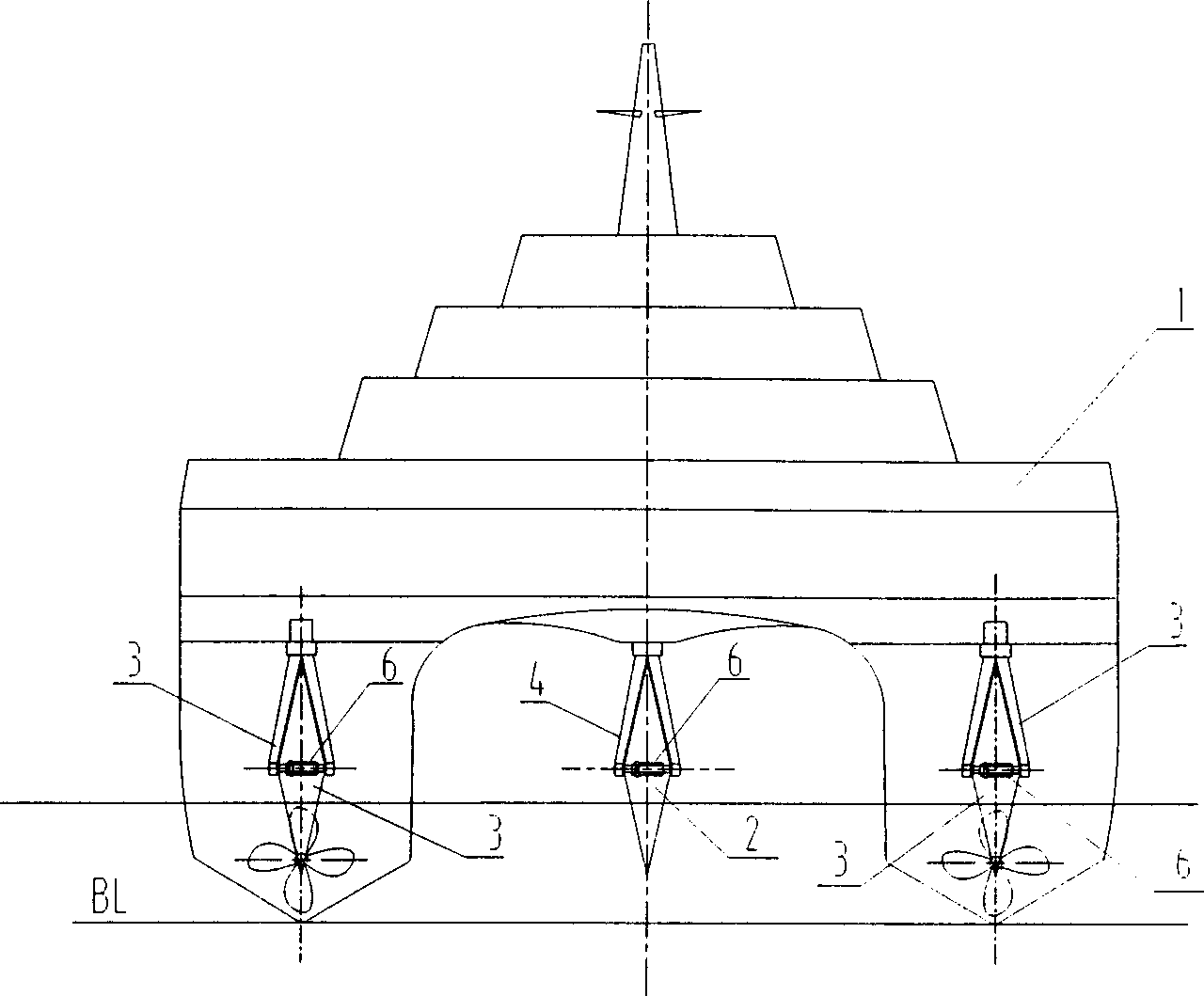

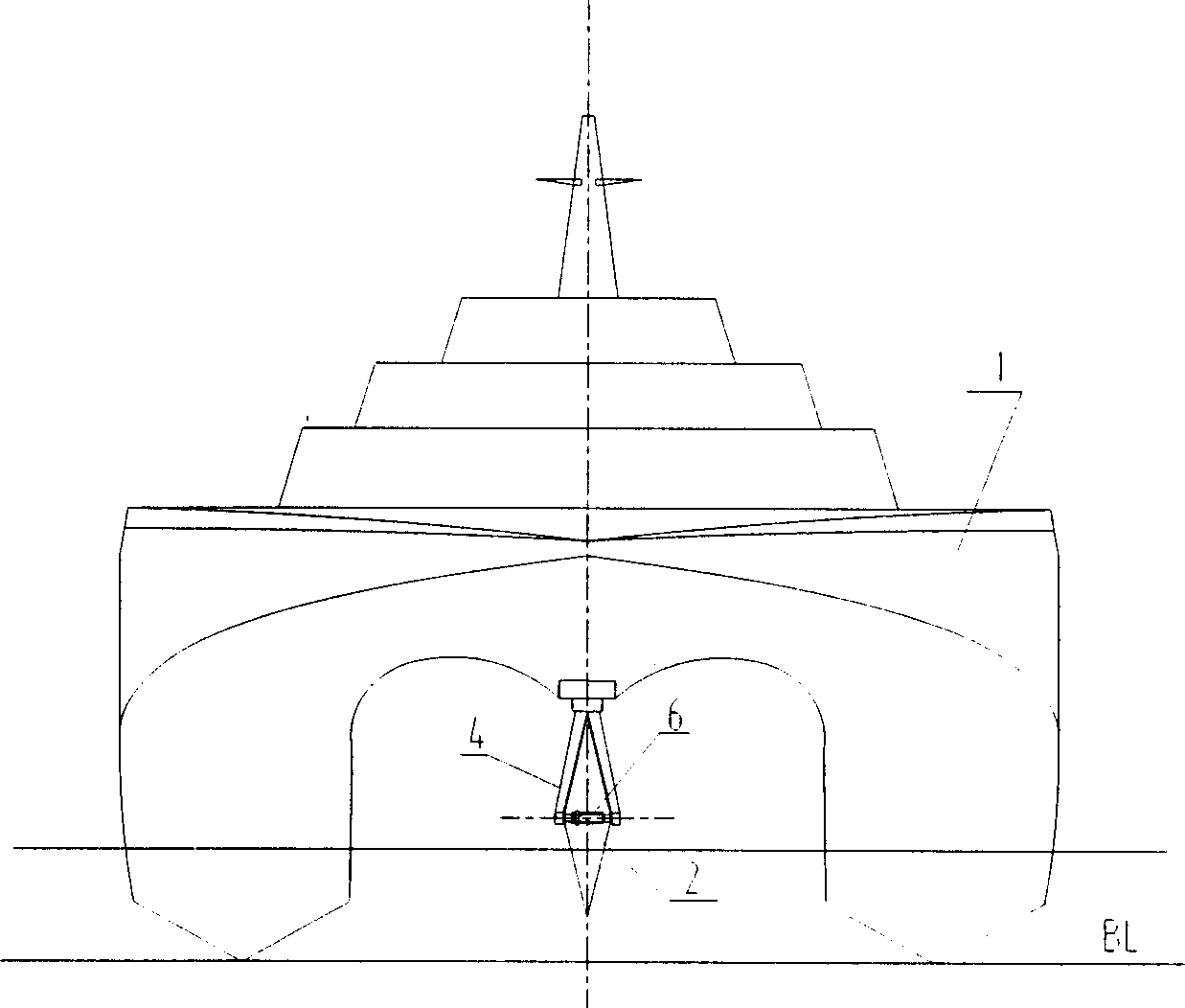

[0028] Such as figure 2 , 3 As shown, the bow rotating appendage 2 and the stern rotating appendage 3 are both hollow watertight structures, reinforced by trusses inside, made of fiberglass, steel, or aluminum alloy, and their side view is circular, with a radius of The design draft of the hull is about 2 / 3-9 / 7, and the section through the rotation axis is as follows Figure 4 , 5 , The rhombus shown in 6 includes regular rhombus, convex rhombus, and concave rhombus, wherein the width of the largest section of the bow turning appendage 2 is about 1 / 10 to 1 / 5 of the spacing between the blades, and the displacement is less than 3% of the total displacement of the hull. The width of the maximum section of the stern turning appendage 3 is less than or equal to the width of the thrust surface of the propeller, and the displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com