Method for extracting vanadium pentoxide from vanadium-containing spent catalyst and petroleum ash

A technology of vanadium pentoxide and waste catalyst, applied in chemical instruments and methods, vanadium oxide, vanadium compounds, etc., can solve the problems of great change in leaching rate and decrease in leaching rate, and achieve stable product quality, high recovery rate, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

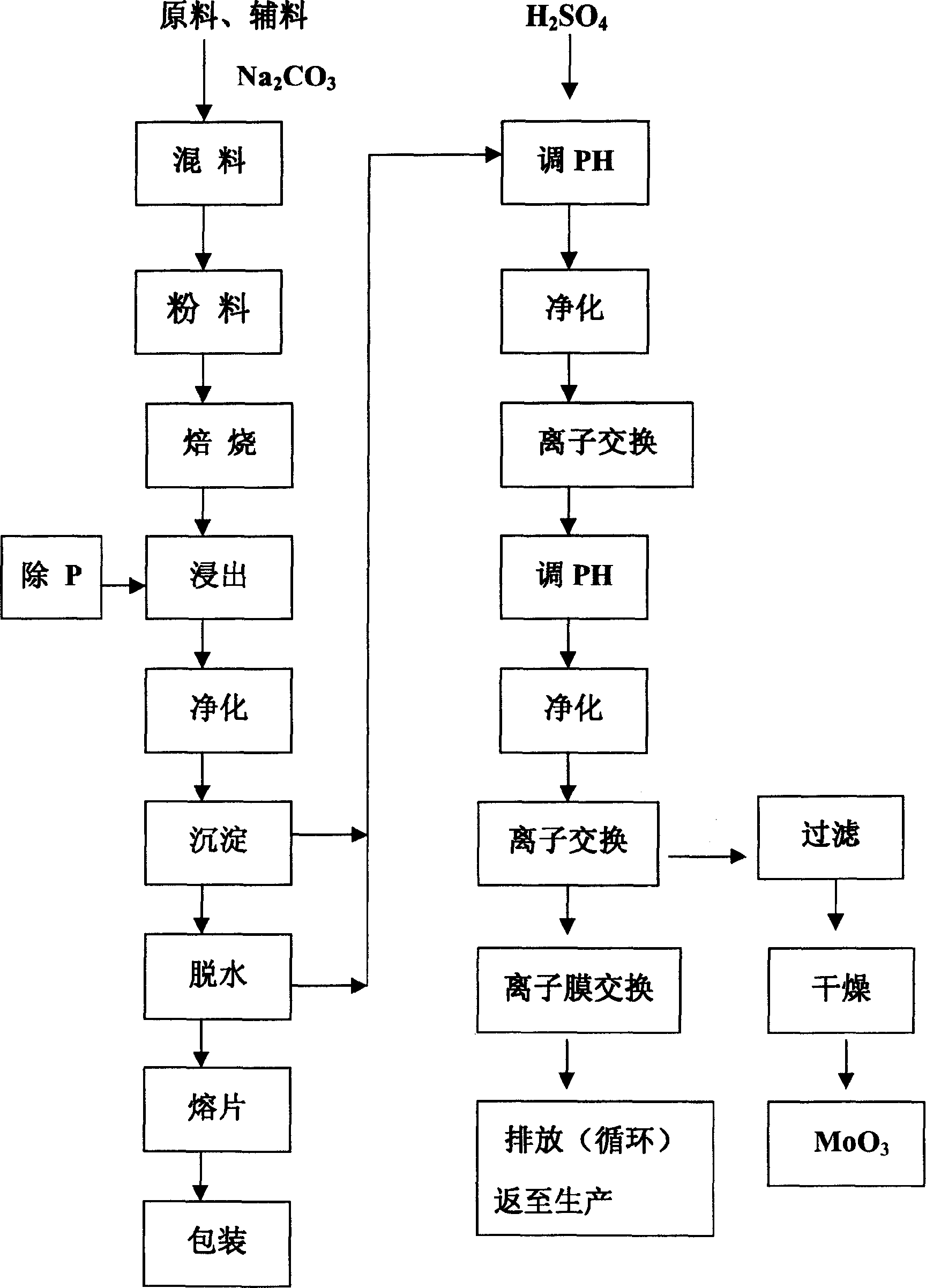

[0069] 1. Pre-mixing: first determine the V in the raw material waste catalyst or petroleum ash 2 o 5 Occupied content, the molar ratio of raw materials according to the production process formula is Na 2 CO 3 :V 2 o 5 =2~4:1, and adding Na 2 CO 3 At the same time, add an appropriate amount of NaCl (excipient), Na 2 CO 3 The ratio of parts by weight and NaCl input is 1:0.1-0.2, to reduce the temperature of sodium roasting, mix in the mixer and then discharge; send it to the storage bin through the belt conveyor for crushing;

[0070] 2. Crushing: Vanadium-containing waste is crushed to 20-40 mesh with a hammer crusher, and the powder is put into the storage bin for standby;

[0071] 3. Sodium roasting: The purpose of sodium roasting is to convert insoluble vanadium compounds into soluble sodium vanadate for leaching and extraction of vanadium pentoxide. The crushed materials are continuously sent to the rotary kiln by the hoist and the feeding bin for roasting. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com