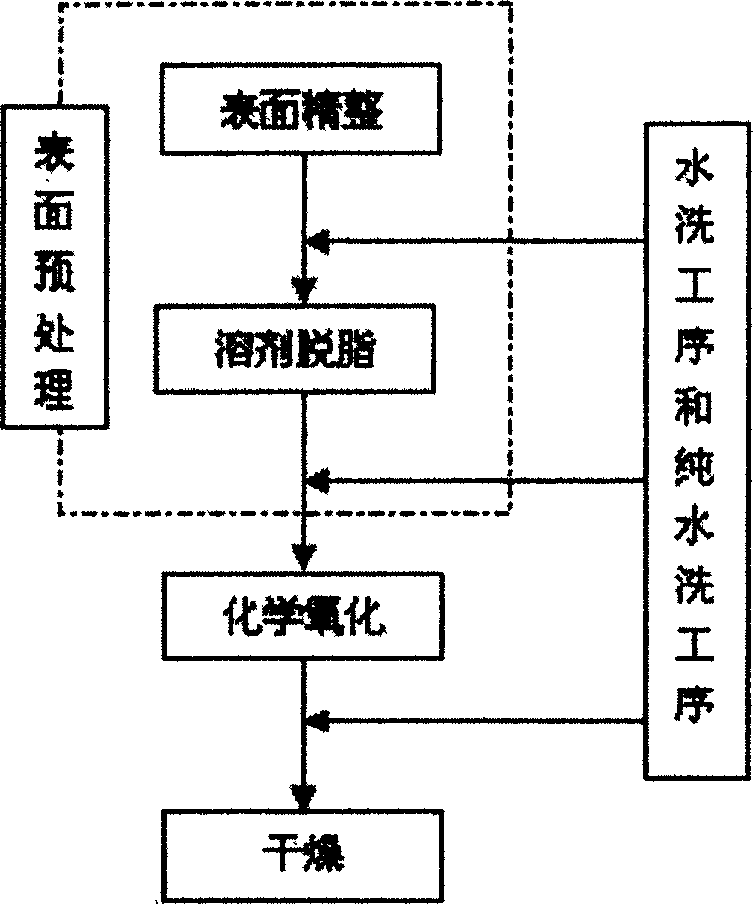

Process for magnesium alloy surface treatment

A surface treatment, magnesium alloy technology, applied in the direction of metal material coating technology, etc., can solve the problem that the degree of corrosion resistance may not meet the requirements, and achieve the effects of strong environmental friendliness, low energy consumption, and low chemical oxidation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Magnesium alloy sample: AZ91 magnesium alloy

[0036] Potassium permanganate [KMnO 4 ] 20g / L

[0037] Zirconium sulfate [Zr(SO 4 ) 2 ] 1.5g / L

[0038] Cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O] 0.5g / L

[0039] Oxidation process: 298K, 8min

[0040] The quality of the film layer is brownish red continuous film layer, dripping time is 24s, and the paint film adhesion is 100 points.

Embodiment 2

[0042] Magnesium alloy sample: ZM61 magnesium alloy

[0043] Potassium permanganate [KMnO 4 ] 30g / L

[0044] Zirconium sulfate [Zr(SO 4 ) 2 ] 1.0g / L

[0045] Cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O] 0.5g / L

[0046] Lanthanum nitrate [La(NO 3 ) 3 ] 0.5g / L

[0047] Oxidation process: 298K, 8min

[0048] The quality of the film layer is brownish red continuous film layer, the drip time is 25s, and the paint film adhesion is 100 points.

Embodiment 3

[0050] Magnesium alloy sample: AZ31 magnesium alloy

[0051] Potassium permanganate [KMnO 4 ] 40g / L

[0052] Zirconium sulfate [Zr(SO 4 ) 2 ] 0.5g / L

[0053] Cerium nitrate [Ce(NO 3 ) 3 ·6H 2 O] 1.0 / L

[0054] Lanthanum nitrate [La(NO 3 ) 3 ] 0.5g / L

[0055] Oxidation process: 298K, 8min

[0056] Film quality, brown-red continuous film, drip time 22s, paint film adhesion 100 points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com