Optical non-contact type narrow angle measuring device

A non-contact, measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of complex structure of the measuring system, limited installation space, large volume, etc., and achieve small size, high precision and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

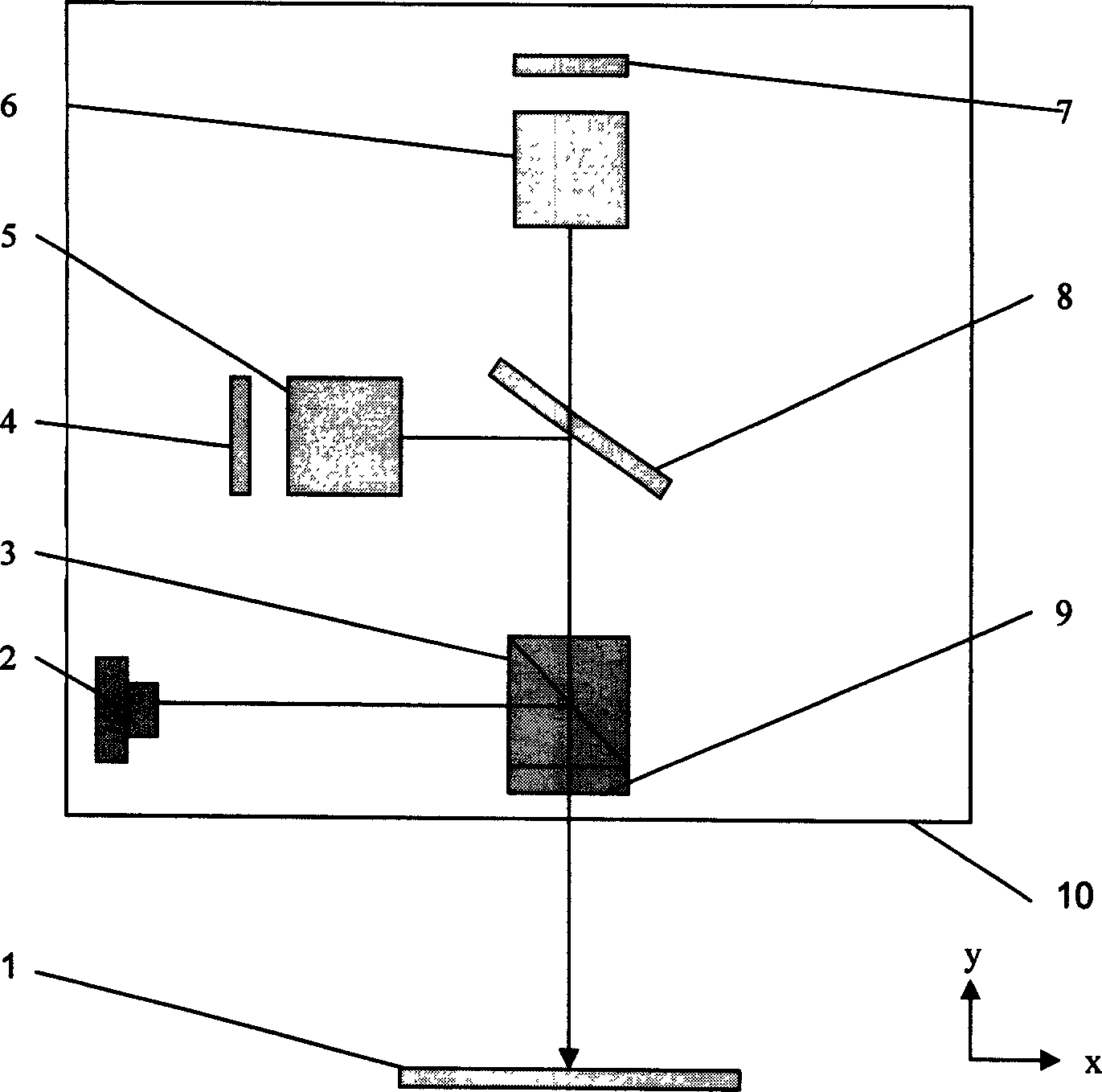

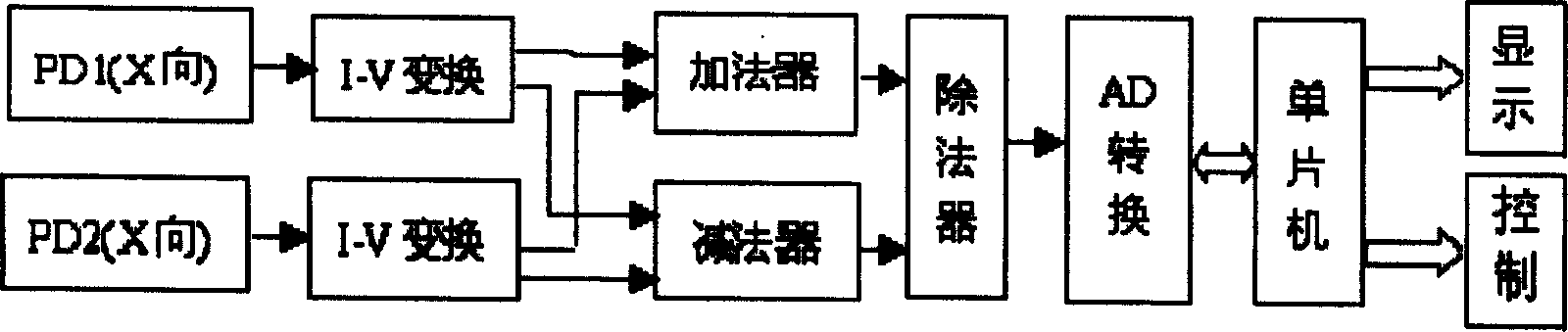

[0010] The optical non-contact small angle measuring device adopts the optical differential angle measuring device to detect the change of the rotation angle of the measured object. The process is: the semiconductor laser is integrated with the collimating lens to form 2 through the clamping frame, and the emitted light After passing through the polarizing beam splitter 3, the S polarized light in it is reflected and then passes through the 1 / 4 wave plate 9 to become circularly polarized light, which is incident on the surface of the object or the reflector 1 fixed on the surface of the measured object, and reflected from the measured reflecting surface Circularly polarized light, after passing through the beam splitter 9, becomes P polarized light, and then through the beam splitter 8, it is divided into two mutually orthogonal beams of equal energy. In 5 and 6, the intensity of the emitted light is detected by photodiodes 4 and 7, respectively. 2, 3, 4, 5, 6, 7, 8, and 9 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com