Atomic force microscope measuring device based on angular measurement

A technology of atomic force microscope and angle measurement device, which can be applied in measurement device, optical device, scanning probe microscopy, etc., and can solve problems such as measurement principle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

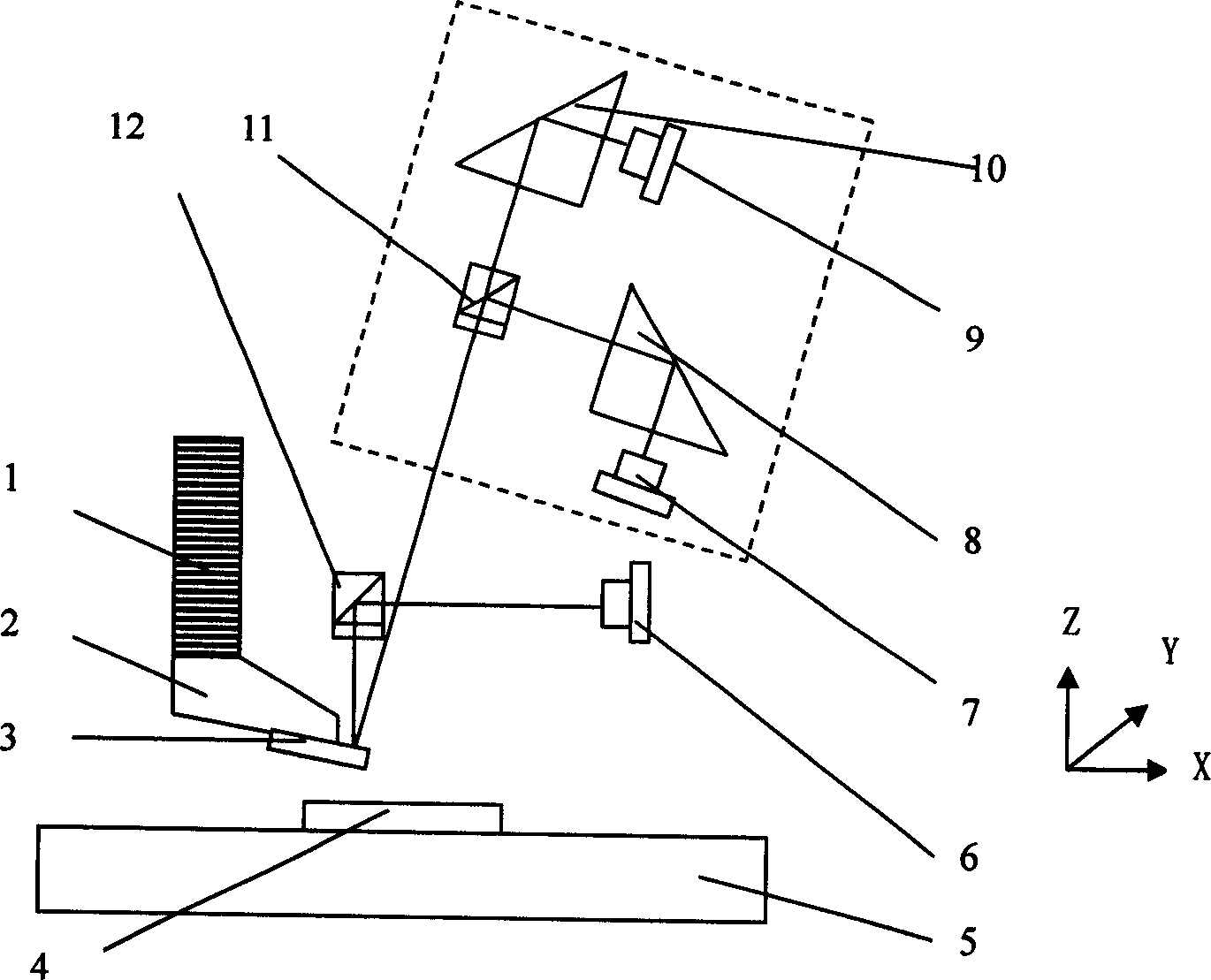

[0009] The AFM measurement method based on angle measurement, the angle change of the tip of the cantilever beam caused by the force change during the scanning process of the AFM probe, adopts the optical differential angle measurement device ( figure 1 inside the dotted line), the process is: the visible light emitted by the laser 6 is reflected by the polarizing beam splitter 12 after the converging lens, passes through the 1 / 4 wave plate, and is incident on the cantilever beam / AFM probe 3 reflective surface of the atomic force microscope, The laser reflected by the AFM probe carries the angle change information of the cantilever beam into the angle measurement device; the angle measurement device is fixed on the adjustable angle platform, which is fixed on the system base; when the initial force measurement is set, it can be It is considered that the output signal of the angle measuring device is "zero"; when the measuring force changes during the scanning process, the bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com