Gasification coal-saving environmental protection normal pressure hot-water boiler

A hot water boiler and normal pressure technology, applied in the design field of new indoor heating hot water boiler, can solve the problems of large consumption of raw materials, lower boiler thermal efficiency, complex manufacturing process, etc., to achieve large heat supply and clean and thorough ash removal , No environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

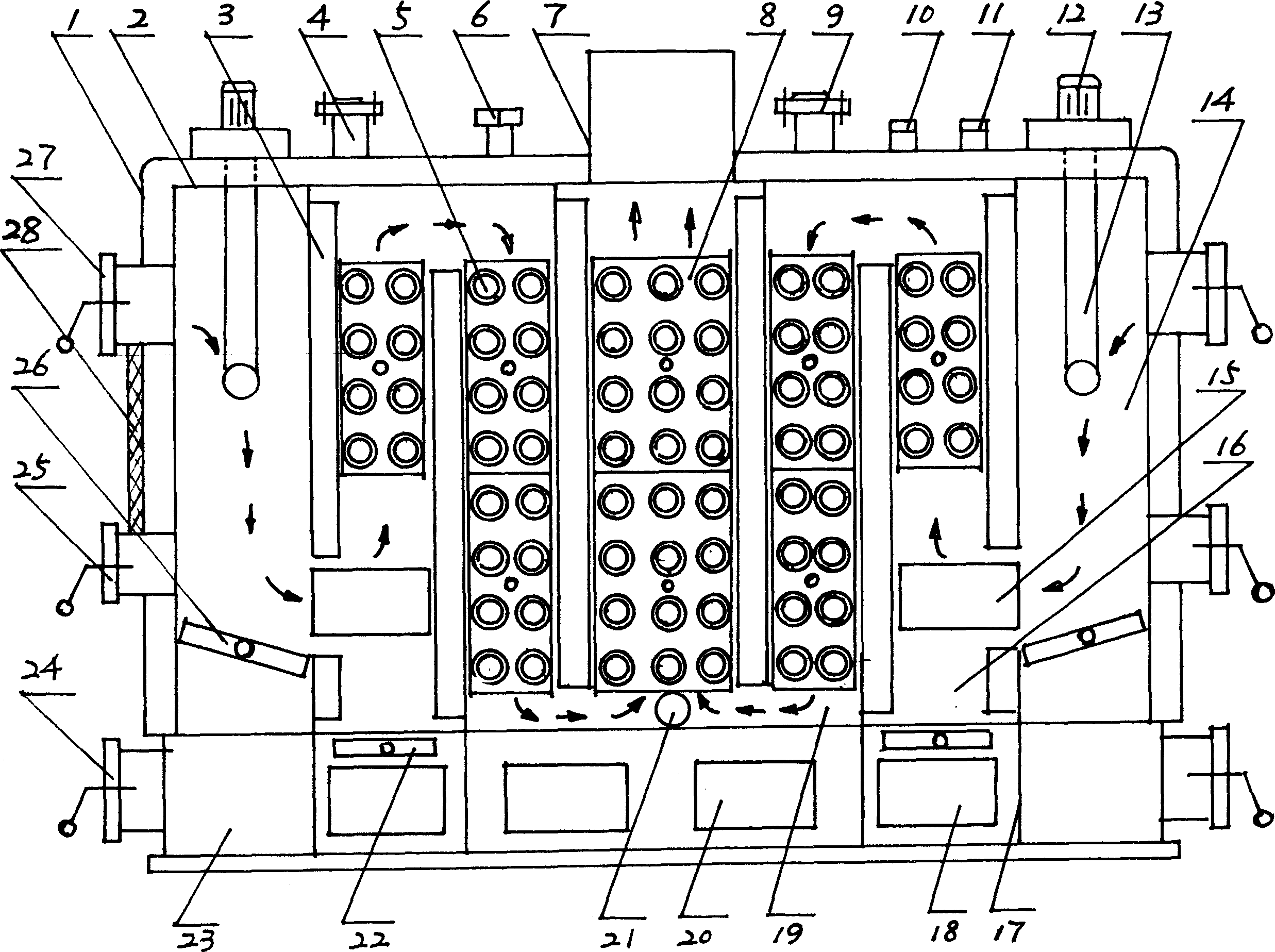

[0014] The gasification, coal-saving and environment-friendly atmospheric hot water boiler of the present invention is realized in this way, which will be described in detail below in conjunction with the accompanying drawings. See figure 1 , in the figure: 1 is the shell of the furnace body, 2 is the furnace, 3 is the water jacket partition, 4 is the water outlet pipe, 5 is the hot water pipe bundle, 6 is the explosion-proof valve, 7 is the flue, 8 is the porous plate pull rod manual cleaning Ash vessel, 9 is the atmospheric communication pipe, 10 is the pressure gauge, 11 is the thermometer, 12 is the blower, 13 is the air duct device, 14 is the gasification combustion chamber, 15 is the side furnace door, 16 is the secondary combustion chamber, 17 18 is the slag cleaning door, 19 is the heat exchange chamber, 20 is the ash cleaning door, 21 is the water inlet pipe, 22 is the movable grate, 23 is the base, 24 is the lower furnace door, 25 is the middle furnace door, 26 is a...

Embodiment 2

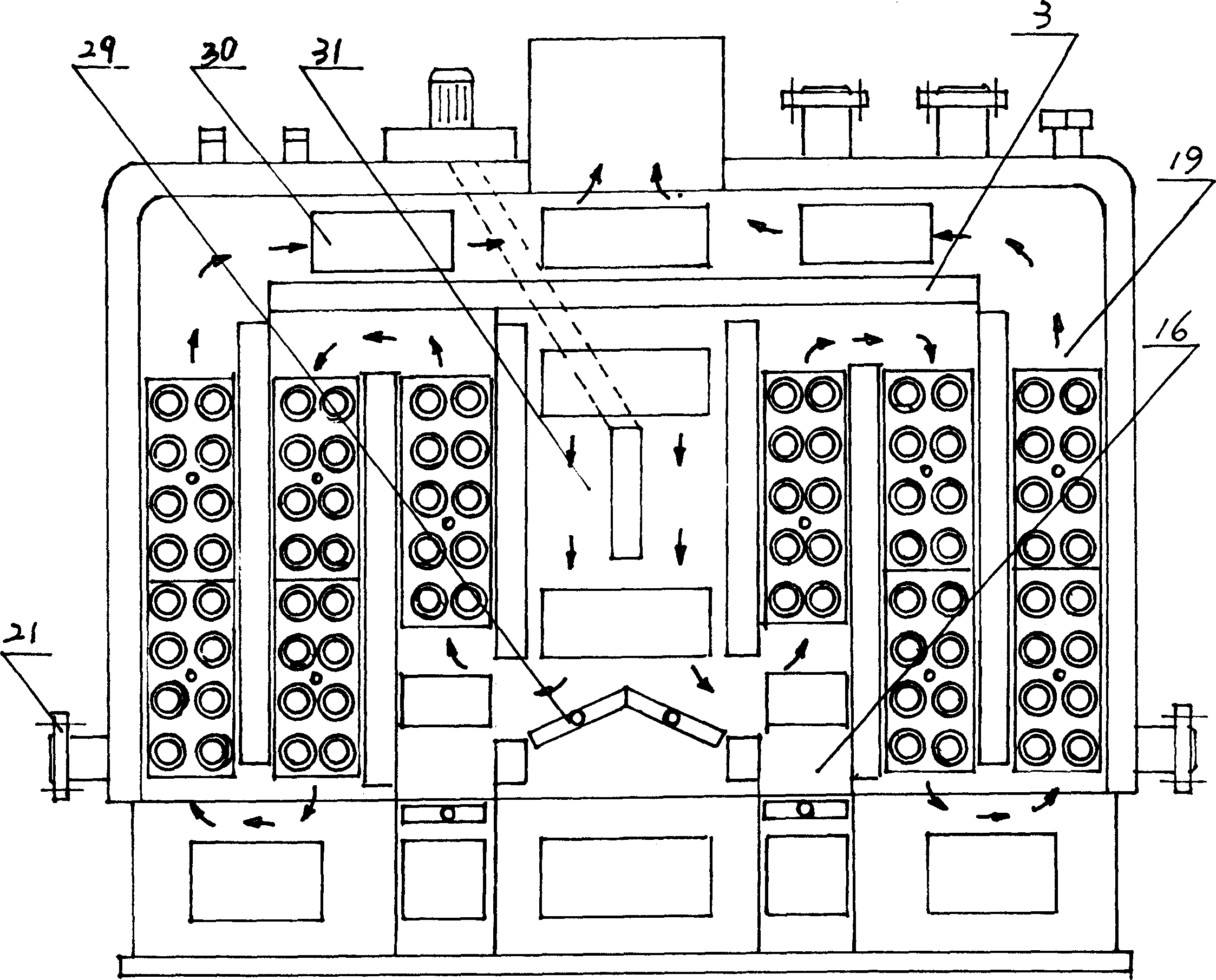

[0019] See figure 2 The structure of the two-way combustion chamber set in the gasification coal-saving environmental protection atmospheric hot water boiler is realized in this way. In the middle of the furnace 2, a two-way gasification combustion chamber 31 is set, and a two-way fire grate 29 is set at the bottom of the furnace body. The upper front and rear of the upper part of the body of furnace are provided with an upper cleaning door 30 . With this structure, the flue gas starts from the center of the furnace 2, goes to both ends, and after going through three processes, it is merged in the central flue 7 and discharged.

Embodiment 3

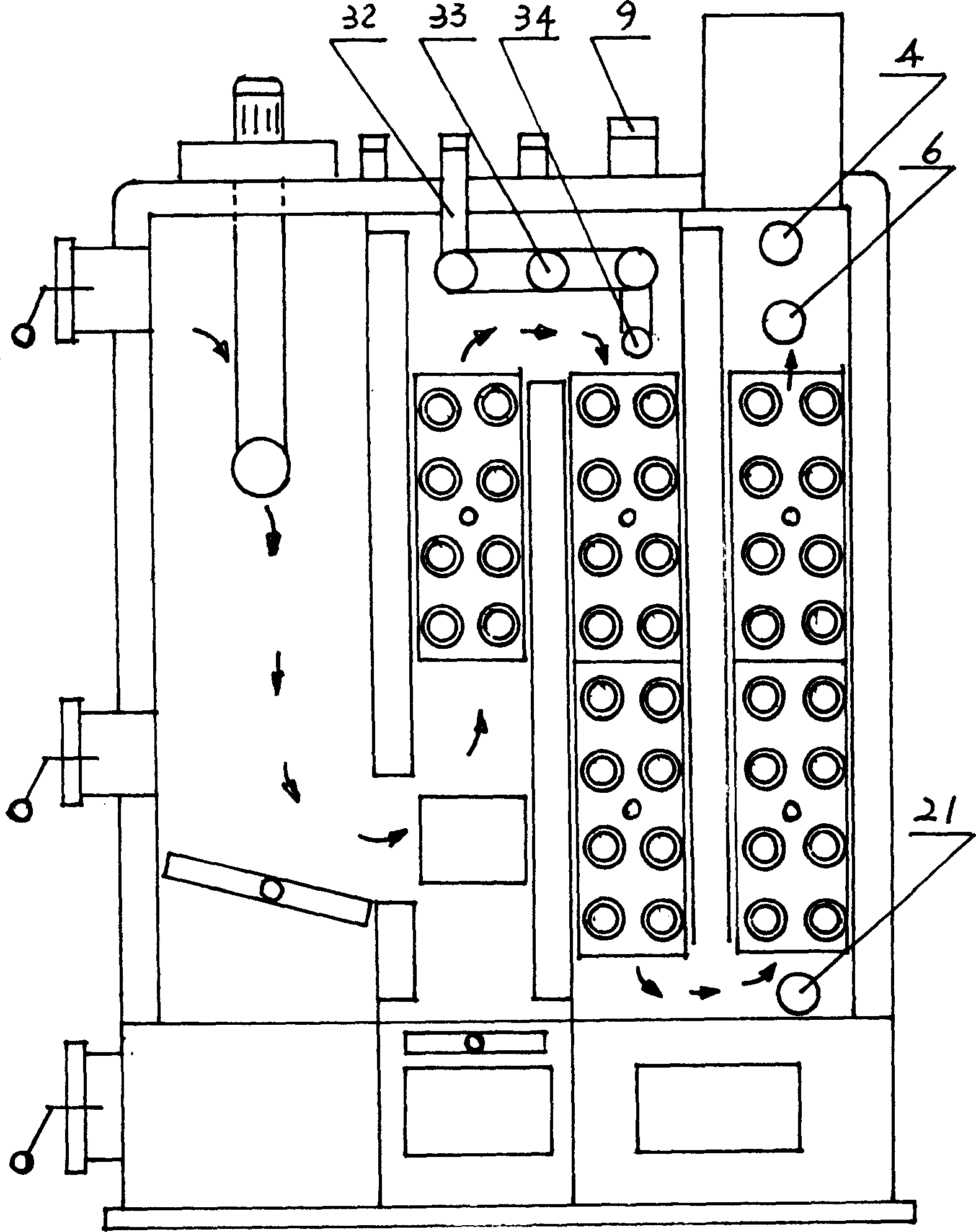

[0021] See image 3 , the bathing heater structure that is set in gasification coal-saving environmental protection normal pressure hot water boiler is realized in this way, heater 33, heater inlet pipe 32, heater outlet pipe 34 are set on the top of furnace liner 2. The flue gas starts from the front of the furnace 2 and is discharged from the flue 7 at the rear of the furnace through three processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com