On-star once image surface calibration method for interference type super spectrum imager

An on-board calibration and hyperspectral technology, which is applied in the directions of using multiple reflections to generate spectra and spectrum generation, can solve the problems of mechanical failures in the background technology and low reliability of on-board calibration, and solve the problems of insufficient light source energy, Improve strength and achieve flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

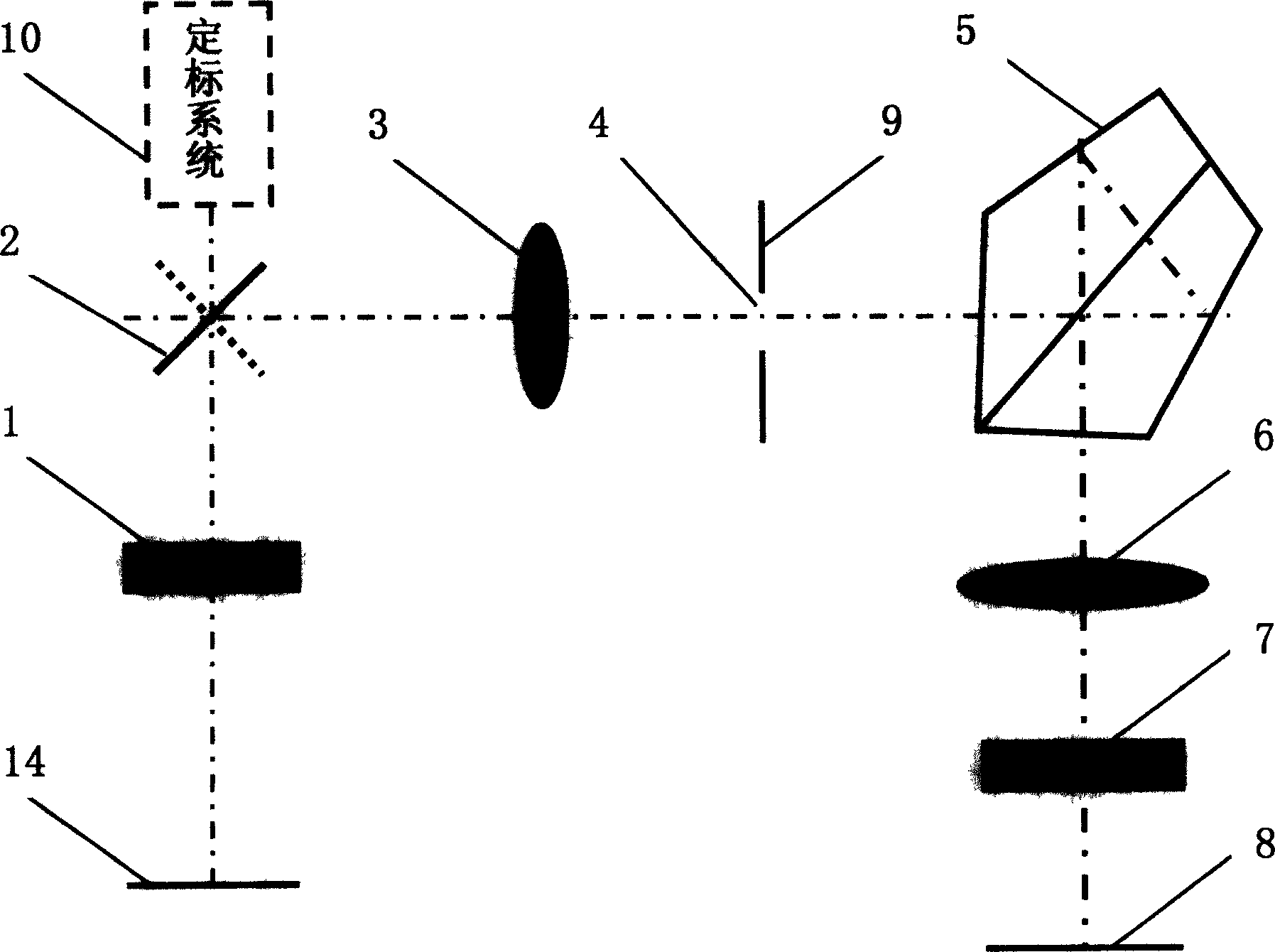

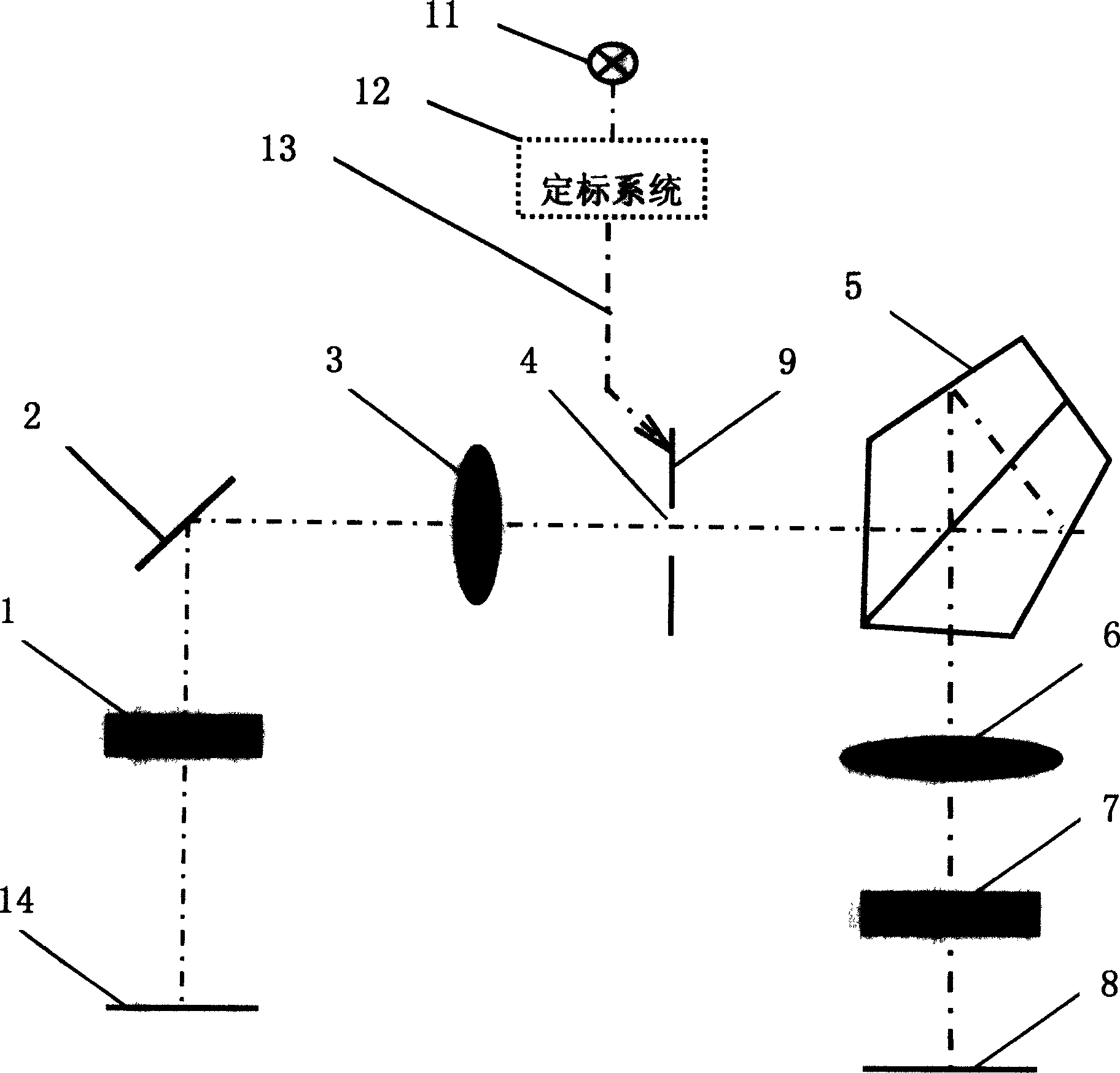

[0023] see figure 2 , the present invention utilizes the characteristics of the principle of the interferometric hyperspectral imager system, introduces a calibration light source 11 on the primary image plane 9, generates an interferogram on the detector image plane, that is, the secondary image plane 8, and realizes relative calibration on the star. Concrete implementation steps of the present invention are as follows:

[0024] 1. The calibration light source 11 passes through the calibration system 12 to generate calibration light 13 that can be imaged at the slit 4 . The position of the introduction point of the calibration light 13 can be any position on the primary image plane 9, which can be selected according to the conditions of the system structure. In order to improve the intensity of the interferogram and meet the requirements of the dynamic range of the detector response, the size of the area of the calibration light 13 on the primary image plane can be select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com